About Us

Executive Editor:Publishing house "Academy of Natural History"

Editorial Board:

Asgarov S. (Azerbaijan), Alakbarov M. (Azerbaijan), Aliev Z. (Azerbaijan), Babayev N. (Uzbekistan), Chiladze G. (Georgia), Datskovsky I. (Israel), Garbuz I. (Moldova), Gleizer S. (Germany), Ershina A. (Kazakhstan), Kobzev D. (Switzerland), Kohl O. (Germany), Ktshanyan M. (Armenia), Lande D. (Ukraine), Ledvanov M. (Russia), Makats V. (Ukraine), Miletic L. (Serbia), Moskovkin V. (Ukraine), Murzagaliyeva A. (Kazakhstan), Novikov A. (Ukraine), Rahimov R. (Uzbekistan), Romanchuk A. (Ukraine), Shamshiev B. (Kyrgyzstan), Usheva M. (Bulgaria), Vasileva M. (Bulgar).

Materials of the conference "EDUCATION AND SCIENCE WITHOUT BORDERS"

Process of mechanoactivation of dry construction mixes promotes increase of energy efficiency of production at the expense of significant increase in a blanket of processed strong substance. In grains of cement there are defects (cracks and dislocations), promoting acceleration of process of interaction of a knitting material with water solutions. Thus potential energy of knitting substance is more fully used and set process by cement of branded durability [15] is intensified.

From the point of view of achievement of high intensity of machining, improvement of quality of production, increase of productivity and energy efficiency of devices the most perspective are electromagnetic mechanoactivators (EMMA) [1,2,3,4,6,15].

In EMMA energy of an electromagnetic field will be transformed to kinetic energy of movement of plate elements which at the minimum costs of power of management transfer this energy in acts of power intense and adjustable contact interactions to grains of a processed material [3,4,11].

The purpose of this work is scientific justification of increase of energy efficiency of production of cement by a way of introduction to the technological line of the electromagnetic mechanoactivator based on a nonconventional way of transfer to mechanical energy by a tear of plate elements with using a quasineutral magnetic field of a direct current.

Material and methods of researches.

Subject of researches is the electromagnetic mechanoactivator for dispergating of construction mixes (cement). For creation of magnetic fields in the working volume of the electromagnetic mechanoactivator the method of the integrated equations is used.

Results of research and their discussion

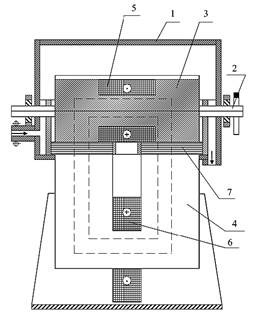

Now the electromagnetic mechanoactivator EMMA C is developed for dispergating of construction mixes (including cement) which constructive scheme and the principle of action represent a subject of the invention [17]. In the developed modification EMMA C (fig. 1) for the purpose of receiving particles of cement of a fragmental form plate ferromagnetic elements with the sharp sides providing shock using-up way of dispergating in combination with cutting [4,5,15] are used.

Fig. 1. Constructive scheme EMMA C:

I - case; 2 - rotor; 3 - cylinder; 4 - portable magnetic conductor, 5, 6 - management windings; 7 - cylindrical plate bodies

The size of power interactions between cylindrical ferromagnetic elements is defined by parameters of an electromagnetic field in working volumes of the activator [4, 8, 12, 13]. For the purpose of providing power effective operating modes at the minimum costs of energy of management (30 W) in designed EMMA C steel sites of a magnetic conductor don't reach a condition of saturation and the size of an induction of an electromagnetic field B in direct ratio depends at most current of I in the management windings (MW) in the range of values from 0,1 to 0,9 A [1,2,4,12,14].

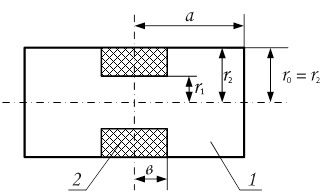

For creation of a magnetic field of a winding with current (OU) in the presence of a cylindrical rotor the method of the integrated equations [4,7] is used. Schemes to creation of magnetic fields in working volume EMMA C are submitted in fig. 2.

Fig. 2. Schemes to creation of magnetic fields in working volume EMMA C:

a – with an internal arrangement of OU on a rotor; - with rectangular portable magnetic circuit

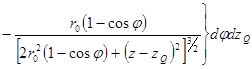

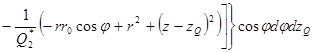

The integrated equation for definition of an unknown current layer looks like

![]() , (1)

, (1)

Where μ, μ0 - respectively magnetic permeability of ferromagnetic plate elements and working volume; ![]() ,

, ![]() - projections of a vector of a magnetic induction to an axis Z (the axis is combined with a device axis) according to a current layer and the multilayered coil with current.

- projections of a vector of a magnetic induction to an axis Z (the axis is combined with a device axis) according to a current layer and the multilayered coil with current.

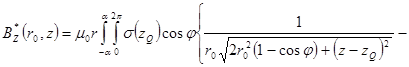

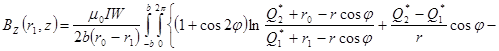

The component ![]() of a magnetic field in working volume is determined by a formula

of a magnetic field in working volume is determined by a formula

, (2)

, (2)

Where r0, 2а - respectively a radius and rotor length.

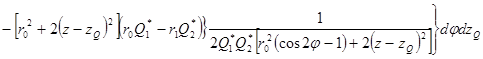

The component ![]() is presented by expression

is presented by expression

![]()

![]()

, (3)

, (3)

Where![]() ;

; ![]()

![]() ,

,

2b, r1 - respectively width and internal radius of OU.

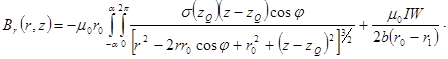

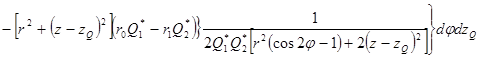

Formulas for calculation of a magnetic field in any point of working volume look like

;

;

![]()

![]()

; (4)

; (4)

![]() ; (5)

; (5)

![]() , (6)

, (6)

Where W-number of rounds of OU

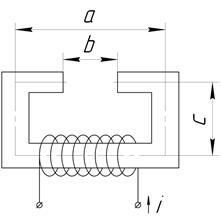

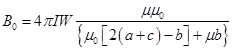

Settlement formulas in a technique of creation of magnetic fields of mechanoactivators with an external arrangement of OU on a portable magnetic conductor are received in the Cartesian system of coordinates. The magnetic field not indignant of a rotor in working volume is uniform

, (7)

, (7)

Where a, c - respectively width and core length.

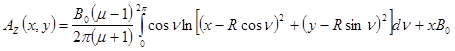

Vector magnetic potential of the field revolted with a rotor looks like

![]()

, (8)

, (8)

where ![]() .

.

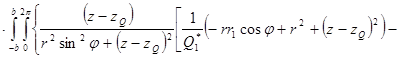

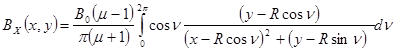

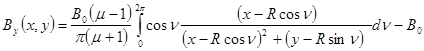

Components ![]() of a vector are defined by expressions

of a vector are defined by expressions

![]()

, (9)

, (9)

. (10)

. (10)

Intensity of a field is calculated by formula

![]() . (11)

. (11)

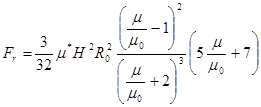

For calculation and the analysis of size of dispersing loadings of Fr in EMMA C at mechanoactivation of cement grains used a formula (12) received on the basis of the analysis and development of dipolar model of D.K. Maxwell [2,4,7,9,16]:

(12)

(12)

The coefficient of volume filling of working volume grinding bodies is considered by the relation![]() . Changing μ0 in limits

. Changing μ0 in limits![]() , it is possible to consider extent of filling of working volume of processing of a product of a ferromagnetic component (here

, it is possible to consider extent of filling of working volume of processing of a product of a ferromagnetic component (here![]() - absolute magnetic permeability). The case corresponds

- absolute magnetic permeability). The case corresponds![]() to empty working volume. At

to empty working volume. At ![]() working volume it is completely filled with plate elements.

working volume it is completely filled with plate elements.

As a result of researches it is established that in EMMA C there are combined processes of homogeneous hashing and thin crushing. Products of a grinding have a fragmental (crushed-stone) form with acute angles and the developed configuration. Such form of particles of cement promotes increase of its physical and chemical activity and an intensification of process of interaction with water solutions.

As a result of the experimental and statistical analysis the method of factorial planning of experiment revealed optimum operating modes EMMA C: the size of an electromagnetic induction in volume of material V=0,38tl processing, coefficient of volume filling of working volume ferromagnetic plate elements of the cylindrical K=0,34 form, the frequency of rotation of a rotor of n=24![]() . By the dispersive analysis with use of analyzers of Frisch firm it is established that in grinding products the mass fraction of particles in the rational range of dispersion from 5мкм to 40 microns makes 74% (a mass fraction of particles the size less 5 microns - 14%, more 40 microns – 12%). Receiving powdery cement with rational granulometric structure and a form of particles promotes its uniform and fast curing. Reduction of expenses of energy at a stage of mechanoactivation of cement grains by 1,3 times is thus revealed.

. By the dispersive analysis with use of analyzers of Frisch firm it is established that in grinding products the mass fraction of particles in the rational range of dispersion from 5мкм to 40 microns makes 74% (a mass fraction of particles the size less 5 microns - 14%, more 40 microns – 12%). Receiving powdery cement with rational granulometric structure and a form of particles promotes its uniform and fast curing. Reduction of expenses of energy at a stage of mechanoactivation of cement grains by 1,3 times is thus revealed.

Conclusion

Introduction EMMA C in a technological production line of cement allows to receive better finished goods and to increase energy efficiency of a production line by introduction of process of electromagnetic mechanoactivation and reduction of expenses of energy at a dispergating stage.

2. Bezzubceva M.M. Teoreticheskie osnovy elektromagnitnogo izmel'cheniya. SPb.: SPbGAU, 2005.160s.

3. Bezzubceva M.M. Energoeffectivniy sposobelectromagnitnoy aktivacii // Mejdunarodniy jurnal eksperimentalnogo obrazovaniya, 2012. №5. S. 92-93.

4. Bezzubceva M.M., Volkov V.S. Teoreticheskie osnovy jelektromagnitnoj mehanoaktivacii. – SPb.: SPbGAU, 2011. 145s.

5. Bezzubceva M.M., Volkov V.S. Elektromagnitnye meshalki. Teoriya i tehnologicheskie vozmozhnosti. Saarbrucken GmbH.: Palmarium Academic Publishing, 2013. 141 s.

6. Bezzubceva M.M., Volkov V.S. Povishenie energoeffectivnosti bezothodnoy tehnologii proizvodstva korma // Materiali Mejdunarodnoy nauchno-prakticheskoy konferencii / Pod. red. A.V.Pavlova.- Saratov: Izd-vo «KUBiK», 2010. S. 133-134.

7. Bezzubceva M.M., Volkov V.S. Teoreticheskie issledovaniya elektromagnitnogo sposoba mekhanoaktivacii // Mejdunarodniy jurnal prikladnih I fundamentalnih issledovaniy. 2012. №5. S 72-74

8. Bezzubceva M.M., Volkov V.S. Issledovanie rejimov raboti electromagnitnih mekhanoaktivatorov // Uspehi sovremenogo estestvoznaniya. – 2012. – № 8 – S. 109-110.

9. Bezzubceva M.M., Volkov V.S. Prikladnaya teoriya sposoba elektromagnitnoy mekhanoaktivacii // Izvestiya Mezhdunarodnoy akademii agrarnogo obrazovaniya, 2013.- T. 3, № 16. S 93-96.

10. Bezzubceva M.M., Volkov V.S. Aktivator dlya tonkogo izmel'cheniya materialov // Innovacionnye tehnologii mehanizacii, avtomatizacii i tehnicheskogo obslujivaniya v APK. Sbornik materialov Mejdunarodnoy nauchno-prakticheskoy internet – konferencii. Orel GAU, 2008. S.122-126.

11. Bezzubceva M.M., Volkov V.S. K voprosu rascheta energetiki rabochego processa v electromagnitnih mekhanoaktivatora (EMMA) // Mejdunarodniy jurnal prikladnih i fundamentalnih issledovaniy. 2012. №57. S 129-130.

12. Bezzubceva M.M., Volkov V.S. Obespechenie usloviy upravleniya processom izmelcheniya produktov v elektromagnitnom mekhanoaktivatore. // Mejdunarodniy jurnal prikladnih i fundamentalnih issledovaniy 2012. №7. S. 93-94

13. Bezzubceva M.M., Volkov V.S. Zubkov V.V. Issledovanie apparatov s magnitoojijennim sloem. // Fundamentalnie issledovaniya, №6 (chast 2). 2013.

14. Bezzubceva M.M., Mazin D.A., Zubkov V.V. Issledovanie koefficienta obemnogo zapolneniya ferromagnitnoy sostavlyayushey v apparatah s magnitoojijennim sloem // Izvestiya SPbGAU, 2011. № 23. S. 371-377

15. Bezzubceva M.M., Kovalev M.E. Aktivizaciya suhih sroitelnih smesey v el-ektromagnitnom mekhanoaktivatore s primeneniem eksergeticheskogo kriteriya dlya ocenki effektivnosti izmelcheniya // Aktualnie problem energetiki APK: Materiali II Mejdunarodnoy nauchno-prakticheskoy konferencii / Pod. red. A.V.Pavlova.- Saratov: Izd-vo «KUBiK», 2011. С. 129-132.

16. Maksvell D.K. Izbrannie sochineniya po teorii electromagnitnogo polya. М.: Izd-vo tehniko-teoreticheskoy literaturi, 1952. 685 s.

17. Pugovkin P.R., Bezzubceva M.M., Svetlov V.V. Elektromekhanicheskoe ustriystvo dlya obrabotki shokoladnih mass. Patent RF № I45788I. - Opubl. v BI № 45, 1989

Bezzubceva M. M., Ruzhyev V.A., Yuldashev R. Z. ELECTROMAGNETIC MECHANOACTIVATION OF DRY CONSTRUC-TION MIXES. International Journal Of Applied And Fundamental Research. – 2013. – № 2 –

URL: www.science-sd.com/455-24165 (20.04.2024).

PDF

PDF