About Us

Executive Editor:Publishing house "Academy of Natural History"

Editorial Board:

Asgarov S. (Azerbaijan), Alakbarov M. (Azerbaijan), Aliev Z. (Azerbaijan), Babayev N. (Uzbekistan), Chiladze G. (Georgia), Datskovsky I. (Israel), Garbuz I. (Moldova), Gleizer S. (Germany), Ershina A. (Kazakhstan), Kobzev D. (Switzerland), Kohl O. (Germany), Ktshanyan M. (Armenia), Lande D. (Ukraine), Ledvanov M. (Russia), Makats V. (Ukraine), Miletic L. (Serbia), Moskovkin V. (Ukraine), Murzagaliyeva A. (Kazakhstan), Novikov A. (Ukraine), Rahimov R. (Uzbekistan), Romanchuk A. (Ukraine), Shamshiev B. (Kyrgyzstan), Usheva M. (Bulgaria), Vasileva M. (Bulgar).

Engineering

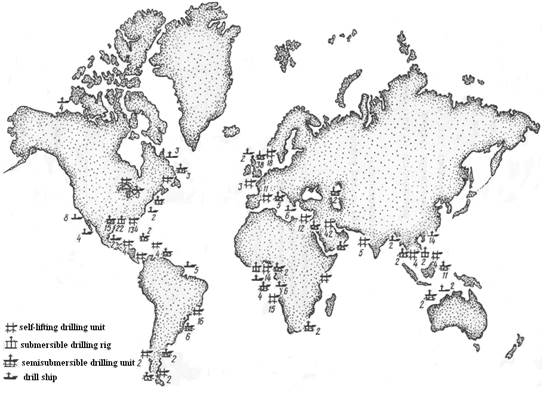

Figure 1. Geographical position of offshore drilling rigs

According to the project of Power strategy of the Russian Federation till 2035 oil and gas production on the shelf of the Arctic sea, the Far East sea and the southern seas is the most perspective direction [1, 2]. The share of oil and gas production on the Russian continental shelf in a total amount of world production of hydrocarbons will reach in 5% for oil and in 10% for gas by 2035. Development of fields of a Russian continental shelf has huge geopolitical, defensive and economic value. It has the following features: severe climatic conditions, difficult ice situation, low geological study of a subsoil and limitation. Sometimes it is impossible to apply traditional methods in ensuring safe operation of drilling rigs [3].

These problems makes it impossible to solve the key technical problems of trouble-free operation of oil and gas platforms. For successful solution of these problems it is necessary to apply the methodology of analysis and risk-based approach to achieve industrial safety.

The negative factors arising at operation of the offshore drilling rigs often have catastrophic consequences as rates of energy allocation are high, and possibilities of localization and accident elimination are limited. Accidents on the offshore drilling platforms can be followed by the big human victims and traumatism. Thermal impact of the fire and toxic influence of products of burning are dangerous for staff owing to the territory limitation of a platform and evacuation difficulties [4].

The first offshore drilling rigs are applied since 1934 at drilling shelves for stationary substructures [5]. World history of development of a continental shelf knows a variety of accidents with catastrophic consequences due to the lack of attention to identify measures and mitigate security threats. The most serious accidents on drilling ships and platforms of various types (semi-submersible, submersible, mobile, stationary) during 1979-2015 are given in Table 1.

Table 1. The list of the major accidents on the offshore drilling ships and platforms since 1979 to the present

|

Date and place |

Type of accident |

A brief description of the accidents and the main causes |

|

25.11.1979 The Chinese Sea |

Flooding of a platform |

The "Bokhay - II" drilling platform got to a 10 points storm when it was been towed at the sea. The platform turned over and sank because of flooding of the pump room. The cause is the violation of transportation rules.72 people were lost. The damage is the platform cost. |

|

15.02.1982 ThecoastofNewfoundland (CanadaCoast) |

Flooding of a platform |

Compartment crash of ballasting management as a result of hit of sea water through the damaged window. "Ocean Ranger" self-lifting table belonging to "Odeko" firm turned over and sank during a storm. The crew of a platform was lost (84 people). The damage is the platform cost. Design shortcomings, unpreparedness and the wrong actions of crew, insufficient quantity of saving means are the causes of an accident. |

|

25.10.1983 The Chinese Sea |

Flooding of a platform |

In a tropical typhoon the "Glomar Dzhava Si" drill ship was ripped from anchors and turned over. The ship sank. 81 people were lost. The damage is the platform cost. |

|

06.07.1988 The North Sea |

Destruction of a platform, burst and fire |

At operation of a gas field on the production deck of the "Piper Alpha" platform there was a number of explosions and a fire. The platform was destroyed.164 people were lost. The damage is the platform cost. |

|

27.07.2005 The Indian Ocean |

Ship collision, destruction of a platform |

The surf wave struck the auxiliary boat standing near a platform so it crashed the platform designs. 49 people were lost. |

|

24.05.2008 The North Sea |

Oil slippage |

There was an oil slippage on the "Statf'ordA " oil-extracting platform. 156 people were evacuated. The part of oil got to the sea. |

|

24.03.2009 Sakhalin Island |

Oil slippage |

There was a failure of drilling rig part on "Molikpak" offshore drilling platform that was extracting oil on the Sakhalin shelf according to the Sakhalin-II project. 165 liters of hydrocarbons got to the ice. The accident consequences were quickly liquidated so there was not a pollution of the sea. |

|

22.04.2010 The Gulf of Mexico |

Fire, burst, large oil slippage |

"Deepwater Horizon" drilling platform sank in the Gulf of Mexico at the coast of Louisiana which was after a powerful explosion on the platform followed by the 36-hour fire. 11 people were lost. |

|

18.12.2011 The Sea of Okhotsk |

Capsizing of the platform |

"Kol'skaya" drilling platform turned over in stormy weather when it was towing from Kamchatka to Sakhalin. The waves were 5-6 meters high and the water temperature was a zero degrees. According to the latest data, only 14 people among 67 victims are rescued. |

|

25.03.2012 The North Sea |

Gas condensate leakage |

There was a large leak of natural gas on "Elgin" offshore platform belonging to "Total" company. The accident caused a security threat of people and environment. |

|

23.07.2013 The Gulf of Mexico |

Flow of gas, burst and fire |

The staff of tried to put the anti-blowout preventer in action, but operation was not successful. 44 people were evacuated. After that there was burst followed by fire. |

|

23.10.2014 The Caspian Sea |

Burst and fire |

On the "SOKAR" platform there were burst and fire. The accident causes are unknown. 12 people fell into the sea. |

|

1.04.2015 The Gulf of Mexico |

Fire on the platform |

There was burst on the "Abkatun Alfa" platform belonging to the Pemex company. The platform lit up. Nearly 300 people were evacuated, 16 people were injured, 4 people were lost. |

In addition, there were 47 cases of less serious accidents during the same period. Dealing with the consequences of each of these accidents cost at more than $ 1 million dollars. Total expenditures for these purposes amounted to $ 201.4 million dollars. From 1955 to 1982 small damages of drilling rigs resulted from storm or collisions. Dealing with the consequences of each of these damages cost less than 1 million dollars and the total cost amounted to $ 14.42 million dollars. (Table 2)

Table 2 - Causes of accidents on offshore drilling rigs

|

The causes of accidents |

The accidents terminated to loss of platforms |

Serious accidents |

Insignificant damages |

|||

|

quantity |

loss, million dollars |

quantity |

loss, million dollars |

quantity |

loss, million dollars |

|

|

Burst and fire |

33 |

521.5 |

19 |

52,1 |

12 |

1,86 |

|

Collision |

- |

- |

2 |

2,0 |

37 |

1,95 |

|

Storm |

24 |

234,6 |

17 |

65,8 |

20 |

6,6 |

|

Round trip of jacket legs |

3 |

21,0 |

13 |

49,9 |

6 |

3,3 |

|

Preparation for transportation |

4 |

205,0 |

- |

- |

1 |

0,1 |

|

Transportation |

9 |

56,2 |

16 |

84,4 |

3 |

0,75 |

|

Drilling |

9 |

59,0 |

11 |

34,8 |

- |

- |

|

Unknown |

10 |

85,5 |

7 |

150,4 |

11 |

3,75 |

Adverse weather conditions, capsizing of a platform by storm and hurricanes, collision of tankers with platforms, leak of hydrocarbons because of depressurization of the equipment owing to corrosion, device shutdown, destruction of a construction, and also wrong or incorrect personnel decisions in critical situations caused by equipment failures and emergency shutdown systems can become the causes of industrial accidents and disasters [6].

Complicating and analyzing of accidents happened on different kinds of offshore drilling rigs makes it possible to combine several integrated and interconnected groups of the causes: uncontrollable blow out of oil and/or gas from wells; integrity violation of supporting structure or supporting pillar bearer and also equipment failure (or technical bugs); personnel errors; technogenic incidents (collision with ships, helicopter crash, sabotage, etc.); natural exposure. Such distribution of accidents shows that the considerable part of accidents happens because of the personnel errors: process disturbance, improper pilotage, berthing wrong to offshore oil and gas facilities. According to statistical data emergency incidents are distributed as shown in Figure 2.

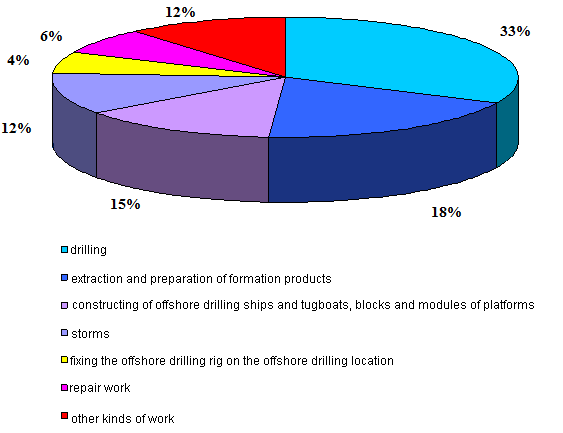

Figure 2. Marine drilling statistics of emergency incidents since 2001 to 2015

As seen in Figure 2, the most part of accidents on the offshore drilling rigs and platforms happens at repair works and a significant part of all accidents happens due to non-compliance of production schedules.

The most common types of accidents at technological operations are emissions, fires and spills (oil spillage). Most of all accidents happens at drilling (33%) and extraction (18%). The less significant accidents happen under displacement of oil and gas field surface facility, booster and technical facilities.

We distributed accidents by types that took place on oil and gas field surface facility in various geographical areas. The results show that 50% of accidents happened on movable oil and gas constructions and about 36% of accidents happened on stationary platforms. There were twice less accidents on the North Sea oil and gas fields than in the Gulf of Mexico. This fact can be explained with a great number of stationary, movable and other constructions, underwater and surface wells in this area.

2. Barakhnina V.B., Khafizova A.A., Kireev I.R. [ High accident rate causes on the offshore oil and gas platforms] Ecological Bulletin of Russia, №2, 2012. — pp. 20–24.

3. Rudenko, S.V. Design stage risk analysis of oil spouter at drilling and operation on the continental shelf oil and gas platforms. Scientific Workshop Proceedings "Industrial safety. Modern methods of technogenic risk analysis in young scientists studies, Scientific and Technical Center "Industrial safety". – M., 2004. – pp. 23-28.

4. Lisanov M.V., Simakin V.V. Accident risk analysis at hazardous production facilities of offshore oil and gas fields // Materials of the II International Conference ROOGD-2008 the "Development of oil and gas resources of the Russian shelf: Arctic and Far East", 2008. – pp. 20-51.

5. Movsum-zade E.M., Mastobaev B.N., Mastobaev Yu.B. i dr. Offshore Oil. Development of techniques and technologies. – SPb.: Nedra, 2005. – 240 p.

6. Safonov V.S., Odishariya G.E., Sheberstov E.V. Scientific Workshop Proceedings "Industrial safety declaration experience and liability insurance. Development of accident risk assessing methods at hazardous production facilities". Scientific and Technical Center "Industrial safety"- M.: OOO «VNIIGAZ», 2003. – pp. 124-142.

Fattakhova E.Z., Barakhnina V. B. ACCIDENT RATE ANALYSIS ON THE OFFSHORE OIL AND GAS PRODUCTION INSTALLATIONS AND PLAT-FORMS. International Journal Of Applied And Fundamental Research. – 2015. – № 1 –

URL: www.science-sd.com/460-24767 (20.04.2024).

PDF

PDF