About Us

Executive Editor:Publishing house "Academy of Natural History"

Editorial Board:

Asgarov S. (Azerbaijan), Alakbarov M. (Azerbaijan), Aliev Z. (Azerbaijan), Babayev N. (Uzbekistan), Chiladze G. (Georgia), Datskovsky I. (Israel), Garbuz I. (Moldova), Gleizer S. (Germany), Ershina A. (Kazakhstan), Kobzev D. (Switzerland), Kohl O. (Germany), Ktshanyan M. (Armenia), Lande D. (Ukraine), Ledvanov M. (Russia), Makats V. (Ukraine), Miletic L. (Serbia), Moskovkin V. (Ukraine), Murzagaliyeva A. (Kazakhstan), Novikov A. (Ukraine), Rahimov R. (Uzbekistan), Romanchuk A. (Ukraine), Shamshiev B. (Kyrgyzstan), Usheva M. (Bulgaria), Vasileva M. (Bulgar).

Engineering

Development of electric networks is one of the most important indicators of the level of electrical power engineering. The most responsible and at the same time more vulnerable link in the mains is overhead power lines (OL). The deterioration of the technical condition of overhead lines in the past decades is one of the main causes of their damageability. The situation is exacerbated by the influence of sleet and wind loads on all the elements of overhead power lines.

Wear of 110 – 500 kV overhead power lines is approximately 60 %, and the failures over the last forty years have increased about twofold, and are due to the aging of materials and climatic influences (38 %) [4].

To efficiently operate OL need modernizing and reconstructing, and a further development of transmission facilities associated with the construction of new overhead power lines requires choosing a strategy for their development.

Relevance of the work is confirmed by the need for the development of concepts that can be a basis for prevention or elimination of failures on overhead power lines during extreme weather influences.

Design of overhead lines should be based on a systematic approach that takes into account the relationship of technical and economic parameters.

Development of concepts

The main task in the construction of overhead power lines is ensuring reliability and economic efficiency of electric networks. Since the life cycle of overhead lines consists of three components: design, installation and operation, it is necessary to consider ways to improve the reliability at these three stages.

A comprehensive indicator Ncom, combining reliable operation Рoper, design Рdes and mechanical strength of OL – ne is proposed as a criterion of reliability Кrel:

![]() (1)

(1)

Project reliability of an overhead power line subject to the adopted calculated mechanical loads on their elements is determined by the expression:

![]() (2)

(2)

where n is the life of an overhead line, [years]

T is repeatability period [years].

The probability of a failure-free operation during a year can be taken as reliability in operation:

![]() (3)

(3)

where ωj is a failure flow parameter for different (j) options to improve the reliability of OL [1 / year].

The mechanical strength of overhead wires is estimated by operational safety factor ne , which shows how many times the maximum specific load on the wire is less than the permissible one:

![]() (4)

(4)

where γ1 and γ7 are specific loads on the wire itself from the mass of the wire mass of and the wires coated with icing and wind, respectively, [N / mm2 · m]

γb - specific load on the wire at which it breaks, [N/m·mm2].

The optimal level of reliability is achieved with a minimum amount of costs Zij of a set of measures to increase reliability and provide compensation Dtij = Dsys + Dcons, where Dsys is system damage, Dcons is damage caused by accidental limitations to the power consumer.

![]() (5)

(5)

where i is a level of reliability

Coper.ij is costs of operation, [thousand. rub.]

Cdif.ij is differentiated tariff, [rub. / KW ∙ h]

δ = ∆Z /∆Нп is rate correction factor,

∆Z is increment of unit operating costs for the supplier, [thou. / KW ∙ h]

∆Нп is increment of specific values of lost profits for the consumer, [thou. / KW ∙ h], with δ > 1 being a supplement to the tariff, δ < 1 – discount, δ = 1 – a constant rate;

∆Wllj, ∆Wn llj are load losses of electricity and no-load losses, [kW ∙ h / year];

![]() is loss

of power on ice melting, [kW ∙ h / year [;

is loss

of power on ice melting, [kW ∙ h / year [;

E is a discount rate;

αд=1/(1+Е)t is a discount factor;

Тcalc a calculation horizon [years].

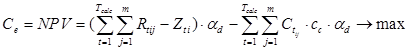

As a criterion of efficiency Ce can be offered a net discount income:

, (6)

, (6)

where NPV is a net discount income, [thousands/rubles];

Rij is an income reached at t – pace of calculation [thousands/rubles];

Ztjis is costs incurred at the t – step, taking into account the damage caused by electricity shortage, [thousand. rub.];

αd is a discount factor;

Ct ij is capital investments in the j – case scenario of OL [thousand. rub.];

cc is a correction factor of capital appreciation;

i is reliability of OL.

Alternative choice of overhead power lines can be done using Pareto methods.

Two approaches to development of overhead lines operating in adverse weather conditions can be marked out for newly designed and created overhead power lines.

The first concept is typical for countries with economies in transition, where economic characteristics do not allow to have a mechanically robust structural element being able to withstand icing and wind loads without the use of ice melting.

The existing Russian regulations provide for less stringent requirements to ensure the reliability of power systems than in the United States and Europe. At the same time, the Russian power systems provides greater use of emergency management.

The basis of the legal reliability in the electric power engineering lies in the Civil Code of the Russian Federation and the Federal Law "On Electric Power Industry". In accordance with the Civil Code of the Russian Federation a power supply company must supply electricity to consumers through the connecting network in the amount stipulated in the contract and in compliance with the feed mode, agreed by the parties. At the same time the level of reliability of power supply is not set firmly and specifically. The number and duration of outages as the main indicators of reliability are determined by the electricity supply company and the consumer in a joint agreement. Civil Code regulates the quality of the energy supplied to meet the requirements set by the "state standards and other mandatory rules." In Russia, "Requirements for the quality of electrical energy in electric networks of general purpose" (GOST R54149-2010)are valid, which, however, does not reflect customer requirements in terms of reliability of power supply, in particular in the number of breaks. In the "Rules for Electrical Installation" (RB-7) reliability index – cut-off times (Т cut-off) is defined and normalized. But the number of breaks is not standardized. Therefore, such a norm in the modern market relations does not reflect the interests of the parties. Rationing of failure is only possible through the use of failure statistics specific to existing networks.

The arguments given above allow us to conclude that Russia's legal framework is not designed to give effect to the economic management mechanism of electricity supply reliability at the stage of formation of contracts [2].

In order to improve the OL design reliability the 7th edition (RB-7) of Electrical Safety Code increased regulatory load return period up to 25 years, changed the method of determining estimated climate loads. Zoning maps on ice and wind strength are revised. In our country and abroad, intensive development in high-tech materials and construction poles, wires, insulators is being conducted.

Main features of the first concept of overhead power line development:

- the main way to deal with icing is ice melting.

Ice melting adversely affects the environment ecology and increases the

cost of electricity transmission in winter due to the increase of power losses

(![]() ) [3].

) [3].

– Period of design loads equal to T = 25 years is not associated with a service life of the main equipment, so it does not reflect the true level of reliability.

– It is not possible to adjust the reliability of economic methods due to the imperfection of the legal framework. The level of reliability of the various categories of consumers is not taken into account. Regulatory documents do not regulate the number and duration of outages. A unit cost of damage compensation is not approved; there are no differentiated by the level of reliability electricity tariffs therefore there is no investment incentives to increase reliability.

– There is no database to monitor indicators such as system reliability, and reliability of power supply for end users.

– All efforts are aimed at improving ice melting systems [1].

The second concept - involves a compromise between the costs of creating lines and costs for their operation. The mechanical strength of overhead power lines and their elements is higher than in the first concept, but also the need for melting ice during operation arises less frequently.

The main objectives: increasing the life and reliability of OL equipment, reducing construction time and costs of its operation.

The main features of the second concept of overhead line development:

– To improve the reliability of the OL project repeatability of standard loads should be agreed with lifetime of structure. Repeatability periods shown in Table 1 can be offered. With an OL length of more than 100 km repeatability period of climatic loads shall be increased in proportion to the length of the overhead line.

Table 1 - Recommended repeatability periods for the second concept

|

i-reliability level |

Repeatability period Т, years |

Probability of no excess of climatic loads, Р |

OL lifetime, n, years |

OL voltage, kV |

Reliability of accepted rated loads Рdes |

|

1 |

25 |

0,96 |

50 |

110 |

0,13 |

|

2 |

35 |

0,97 |

50 |

220 |

0,235 |

|

3 |

50 |

0,98 |

50 |

330 and more |

0,36 |

– Controlled rate of power outages should be approved for different categories of consumers.

– Differentiated tariffs for consumers of different reliability categories should be developed [5].

– To calculate the damages caused by a power interruption it is necessary to develop a differentiated unit cost of power supply interruption damage.

It is necessary to identify optimal settlement and off-design (including force majeure) conditions, a degree of responsibility of subjects depending on these conditions, as well as mechanisms for redress through the insurance system. A contractual relationship system should serve as an essential tool for implementing economic and regulatory reliability management system. Companies build their relations on a contractual basis. Assessment of costs allows justifying the selling price of electricity at the prescribed level of reliability in the contract, and damage assessment allows justifying a starting point for determining a fine amount. Correctly set level of reliability minimizes losses to both suppliers and consumers of power [6].

- Mechanical strength of OL is increased through the use of high-tech equipment that can withstand icing and wind situations: polyhedral metal poles; special wires and lightning protection cables impervious to icing (wire brand AERO-Z), high-temperature wire (GTACSR, TACSR ACS and others), Curie couplings, intraphase spacers (dampers), interphase insulating spacers, silicone polymer insulators, special design line fittings of increased wear resistance, annular protection of polymeric materials, etc.

Use of fluctuation limit wires (wire vibration limiters and ground wire type of eccentric loads and loads of pendulum type, etc.).

Rejection of ground wires (installation of surge arresters or long spark dischargers).

- Reducing by half the length of the span by inserting additional support in areas prone to large overhead line icing and wind loads.

Improvement of OL operation:

- during the operation period ice melting, as an additional means of improving the overhead lines reliability can be partially applied;

- introducing in electric networks of automated information system monitoring the icing (equipping the line with monitoring, operating in real time operation mode, applying thermodynamic monitoring method) [7, 8.9];

- timely implementation of security measures to maintain the temperature at a level that prevents ice build-up;

- improving ice melting schemes.

This concept is proposed as a major in the transition period of the Russian economy.

Elaboration of overhead power line development options

According to the proposed concept four options of a 110 kV overhead line were elaborated.

Option 1. Stringing wires of AERO-Z 301-2Z brand on concrete supports of PB 110 -5 reinforced concrete (RC) type.

Option 2. Wire of GTACSR 240/40 (wire clearance) brand, concrete supports of PB 110 -5 RC type. During icing current load is planned to increase due to the current load circuit events.

Option 3. Wire of TACSR ACS 240/40 brand, metal lattice towers of P-110 -5 ML type and reduction of intermediate span by 30 %.

Option 4. Wire of AC 240 / 39 brand, metal multi-faceted support of PS 35 / 110 PU – 9 type, an intermediate span between supports halved.

Adopted repeatability period T = 35 years.

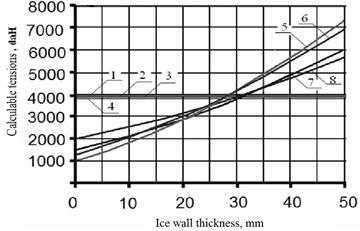

Dependences of the total tension Тυ.ic. in wires under icing and wind loads (Figure 1) are built.

|

|

1 – Тdop (ТACSR 240/40); 2 – Т dop (GТACSR 240/40); 3 – Т dop (Aero-Z 301-2Z); 4 – Т dop (АС 240/40); 5 – Тυ.ic. (GТACSR 240/40); 6 – Тυ.ic. (TACSR 240/40); 7 – Тυ.ic. (АС 240/40); 8 – Тυ.ic. (Aero-Z 301-2Z)

|

Figure 1 - The total tension in wires in pure ice

with a density of 900 kg / m3 and wind at velocity of υ = 8 m / s

Comparative analysis of the calculation results showed:

1. When replacing an ACSR wire with an AERO-Z wire investments increase 2,19 – fold, and the reliability of the line increases 3,08 – fold.

2. When replacing an ACSR wire with a GTACSR (Gap-Type Thermal-Resistant Conductor) wire investments increase 1,33 – fold, the reliability increases 2,17 – fold.

3. When replacing the reinforced concrete poles with metal lattice towers, reducing the span distance by 30 % and replacing an ACSR wire with a TACSR (Aluminum Alloy Conductor Steel – Reinforced) wire investments increase 3,38 – fold and reliability increases 2,25 – fold.

4. When replacing concrete supports with multifaceted metal ones and reducing span distance twice investments increase 1,19 – fold, the reliability does 3,17 times.

Conclusions:

1. The main reasons for the decline in reliability of electric overhead lines: equipment aging and impact of extreme weather conditions.

2. For the transition period of the Russian economy, a concept of overhead line development is brought forward which permits to control reliability by economic methods requiring improvement of the legal framework and introduction of modern high-tech equipment.

3. An alternative concept of overhead power line construction is brought forward permitting to increase the efficiency of investment in the construction of overhead lines operating in adverse weather conditions.

2. Bereznev, Y.I. On the problem of reliability of power supply / Y.I. Bereznev // Power Engineering Specialist. – 2007. – № 10. – pp. 24-25.

3. Diagnosis, reconstruction and operation of overhead power lines in the glaze areas: tutorial. /I.I.Levchenko, A.S.Zasypkin, A.A.Alliluev, E.I.Satsuk. – M .: MEI Publishing House, 2007. – 448 p .: Ill.

4. Improving the efficiency of 110-220 kV overhead power lines icing areas. Monograph. / G.G.Ugarov, N.Y. Shevchenko, Y. Lebedeva, A.G.Soshinov. M .: Pero, 2013. 187 p.

5. Improvement of the tariff system for electricity / N.V. Gusev, N.Y. Shevchenko, A.G. Soshinov, Y. V. Lebedeva // Bulletin of the Nizhny Novgorod University after N.I. Lobachevsky. - 2010. – № 5, ch. 1. – pp. 277-280.

6. Measures to reduce sleet and wind accidents in electrical networks / M.V. Panasenko, N.Y. Shevchenko, N.P. Khromov, A.G. Soshinov // Electrical equipment: maintenance and repair. – 2014. – № 8. – pp. 30 -37.

7. Monitoring the intensity of glazed frost building on overhead power lines and contact networks / D.E. Titov, G.G. Ugarov, A.G. Soshinov // Power Stations. – 2014. – № 11. – pp. 42-46.

8. Shevchenko N.Y., Y.V. Lebedeva, Khromov N.P., Soshinov A.G. Implementation of an automated surveillance system of icing monitoring in Kamyshin electrical networks // Modern problems of science and education. – 2009. – № 5 – pp. 127-132 URL: www.science-education.ru/33-1246 (access date: 04/23/2014).

9. Thermodynamic method for monitoring sleet deposits on wires / D.E. Titov // Electrical equipment: maintenance and repairs. – 2014. – № 4. – pp. 37-44.

Shevchenko N.Yu., Lebedeva Yu.V., Soshinov А.G. 110-220 kV OVERHEAD POWER LINES DEVELOPMENT CONCEPTS IN GLAZE-ICE AREAS. International Journal Of Applied And Fundamental Research. – 2016. – № 4 –

URL: www.science-sd.com/466-25028 (16.04.2024).

PDF

PDF