About Us

Executive Editor:Publishing house "Academy of Natural History"

Editorial Board:

Asgarov S. (Azerbaijan), Alakbarov M. (Azerbaijan), Aliev Z. (Azerbaijan), Babayev N. (Uzbekistan), Chiladze G. (Georgia), Datskovsky I. (Israel), Garbuz I. (Moldova), Gleizer S. (Germany), Ershina A. (Kazakhstan), Kobzev D. (Switzerland), Kohl O. (Germany), Ktshanyan M. (Armenia), Lande D. (Ukraine), Ledvanov M. (Russia), Makats V. (Ukraine), Miletic L. (Serbia), Moskovkin V. (Ukraine), Murzagaliyeva A. (Kazakhstan), Novikov A. (Ukraine), Rahimov R. (Uzbekistan), Romanchuk A. (Ukraine), Shamshiev B. (Kyrgyzstan), Usheva M. (Bulgaria), Vasileva M. (Bulgar).

Engineering

The aim of the present work is to identify the extent of hardening the surface of steel 30KHGSN2A and dynamics of the fracture processes at different frequencies and schemes of cyclic loading.

With increasing frequency cyclic loading, the slope of the curve of fatigue is markedly reduced [4]. This is due to the increase in the hardening of the material of the surface layers of steel 30KHGSN2A.

To ascertain the extent of cyclic hardening on the cross section of sample was prepared microsection in the fracture zone.

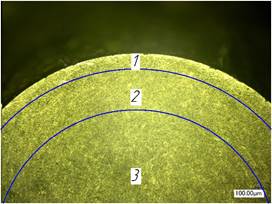

Fig.1. Microstructure illustrating the depth of hardening in the cross section of a steel sample after cyclic deformation in the bending of a rotating sample with a diameter of 5 mm, σ = 1010 MPa, N = 1.4 • 104 cycles, ω = 50 Hz.

Figure 1 shows the etched groove with a 2% solution of nitric acid, on which three zones are clearly visible: 1 - hardening zone; 2 - transition zone; 3 - the central zone. The area of ??hardening of the investigated material occupying a considerable part of the transverse area of ??the sample is shown in Fig. 1 at number 1. This zone is characterized mainly by a martensitic structure. At number 2, this figure indicates a transition zone in which the bainitic structure formed in the process of standard heat treatment is observed to a greater extent. It is obvious that the formation of the last due to the low rate of heat removal during quenching samples, which led to the formation of both types of structures (such as martensite and bainite). The central zone shown in Figure 1 has a troostito-sorbitol structure.

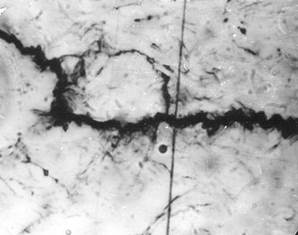

Figure 2. shows the microstructure of the general view of the main fatigue crack of steel after the cyclic flat bending of the sample.

Fig.2. Microstructure of the general view of the main fatigue crack.

The generation stage of a main fatigue crack is characterized by the presence of a large number of local plastically deformed volumes, as evidenced by the scale of the area of hardening (Fig. 1) which are the sources of occurrence of microscopic cracks, in this case, one of which turned into a main crack. Disclosure of the main cracks occurred in waves (Fig. 2) with periodic change of the sign of rotation may change the direction of growth of fatigue cracks associated with the selection of the optimal crystal slip systems (rotation with an invariant lattice with allowance for translational and rotational modes of plasticity), which change their direction in the process of cyclic deformation and phase changeover.

Thus, the wave character is shown in the distribution of plastic changes and associated fatigue cracks, and thus develop the deformation mechanisms of the rotary type (fragmentation of the material, the formation of local zones of bending-torsion, shirring surface, etc.).

2. Shetulov D.I., Myl'nikov V.V. Fatigue-induced damage of high-strength steels // Russian metallurgy (Metally). 2014. Т. 2014. No. 3. С. 241-245.

3. Mylnikov V. V., Shetulov D. I., Chernyshov E. A. On evaluation of durability criteria in carbon steels // Metals Technology. 2010. No. 2. p. 19.

4. Mylnikov VV, Shetulov DI, Pronin AI, Chernyshov EA Forecasting the strength and durability of materials of machine parts and structures, taking into account the frequency of cyclic loading // Izvestiya Vuzov. Ferrous metallurgy. 2012. No. 9. pp. 32-37.

Kondrashkin O.B., Mylnikov V.V., Chernyshov E.A., Shetulov D.I., Romanov A.D., Pronin A.I. CYCLIC HARDENING AND STAGES OF DESTRUCTION OF HIGH-STRENGTH STEEL. International Journal Of Applied And Fundamental Research. – 2017. – № 3 –

URL: www.science-sd.com/471-25281 (16.09.2025).

PDF

PDF