About Us

Executive Editor:Publishing house "Academy of Natural History"

Editorial Board:

Asgarov S. (Azerbaijan), Alakbarov M. (Azerbaijan), Aliev Z. (Azerbaijan), Babayev N. (Uzbekistan), Chiladze G. (Georgia), Datskovsky I. (Israel), Garbuz I. (Moldova), Gleizer S. (Germany), Ershina A. (Kazakhstan), Kobzev D. (Switzerland), Kohl O. (Germany), Ktshanyan M. (Armenia), Lande D. (Ukraine), Ledvanov M. (Russia), Makats V. (Ukraine), Miletic L. (Serbia), Moskovkin V. (Ukraine), Murzagaliyeva A. (Kazakhstan), Novikov A. (Ukraine), Rahimov R. (Uzbekistan), Romanchuk A. (Ukraine), Shamshiev B. (Kyrgyzstan), Usheva M. (Bulgaria), Vasileva M. (Bulgar).

Engineering

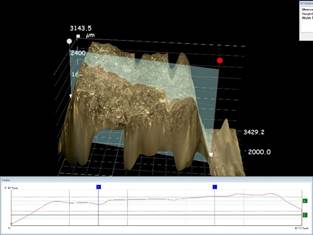

Study of fractured surfaces was performed using optical microscope KEYENCE VHX-1000 with enhanced capabilities through improved telephoto optical system and digital image processing.

a)

a)

b)

b)

c)

c)

Figure 1,a shows a macroscopic view of the fracture surface of a flat specimen with the smallest number of inclusions of the solid phase, consisting of a fibrous zone with regions of randomly arranged fibers without any preferential orientation. The foci of destruction and the zone of nucleation of the crack are indeterminate (Figure 1,b), which is associated with the stability of the process of high-energy propagation of the fracture during destruction. The fracture is characterized by a morphologically uniform destruction surface, i.e. homogeneous in macro geometry without geometric zones that differ significantly in the relief with the presence of the same type of fracture elements, which is shown in Fig. 1, b as a characteristic of the degree of unevenness of the fracture surface in a direction perpendicular to the plane of application of the load. A small amount of dispersed inclusions in the matrix of the material under study at considerable distances leads to the formation of low ridges in some directions, which can be explained by the fact that they are circumvented or bent by the front of the crack propagation, to which this advance is simpler than for the body of high-hard phases. In this case, the polycrystalline nature of the structure (grain structure) determines the fact that the front of material destruction undergoes a slight branching.

2. Romanov D. A., Chernyshov Y. A., Mylnikov V. V., Romanova E. A. Development of technology for obtaining composite material based on aluminum // international journal of applied and fundamental research. 2014. No. 12-2. P. 176-179.

4. Chernyshov E. A., Mylnikov V. V., Romanov D. A., Romanova E. A. development of a method to manufacture cast multicomponent systems with a given size and distribution of nonmetallic reinforcing particles // Modern problems of science and education. 2014. No. 6. P. 324.

3. Chernyshov E. A., Investigation of the microstructure aluminating particulate-filled cast composite material obtained by internal oxidation / E. A. Chernyshov, Lonchakov S. Z., A. D. Romanov, V. V. Mylnikov, E. A. Romanova // advanced materials. 2016. No. 9. P. 78-83.

Mylnikov V.V., Romanov A.D., Chernyshov E.A., Shetulov D.I., Pronin A.I., Kondrashkin O.B. THE DESTRUCTION OF THE TENSILE DISPERSION-STRENGTHENED COMPOSITE MATERIAL. International Journal Of Applied And Fundamental Research. – 2017. – № 3 –

URL: www.science-sd.com/471-25283 (15.12.2025).

PDF

PDF