About Us

Executive Editor:Publishing house "Academy of Natural History"

Editorial Board:

Asgarov S. (Azerbaijan), Alakbarov M. (Azerbaijan), Aliev Z. (Azerbaijan), Babayev N. (Uzbekistan), Chiladze G. (Georgia), Datskovsky I. (Israel), Garbuz I. (Moldova), Gleizer S. (Germany), Ershina A. (Kazakhstan), Kobzev D. (Switzerland), Kohl O. (Germany), Ktshanyan M. (Armenia), Lande D. (Ukraine), Ledvanov M. (Russia), Makats V. (Ukraine), Miletic L. (Serbia), Moskovkin V. (Ukraine), Murzagaliyeva A. (Kazakhstan), Novikov A. (Ukraine), Rahimov R. (Uzbekistan), Romanchuk A. (Ukraine), Shamshiev B. (Kyrgyzstan), Usheva M. (Bulgaria), Vasileva M. (Bulgar).

Engineering

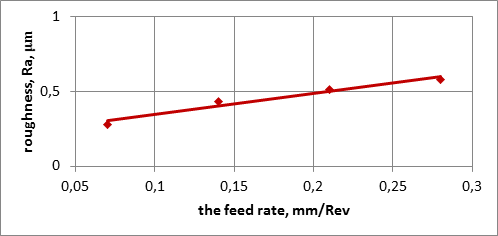

An analysis of the influence of the feed on the roughness of the treated surface is shown in Fig. 1. The results of the influence of the feed amount on the roughness of the treated surface are as follows: increasing the feed amount from 0.08 to 0.24 mm / rev causes accordingly an increase in the surface roughness.

Fig. 1. Flow effect on machined surface roughness at cutting speed V = 390 m/min; depth of cut t = 0.2 mm.

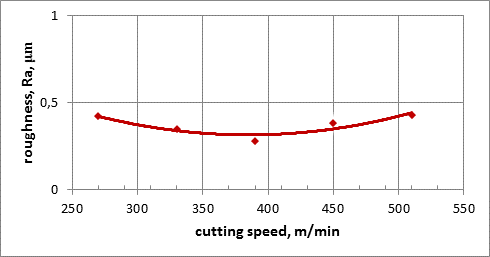

Figure 2 shows the impact of changes of cutting speed on roughness of machined surface.

Fig. 2. The influence of cutting speed on roughness of machined surface at the feed rate S = 0.07 mm/Rev; depth of cut t = 0.2 mm

In the interval of cutting speeds from 260 to 390 m/min, the roughness parameter Ra decreases. In the cutting speed range between 360 and 420 m/min, the roughness is a little resistant due to the reduction components of the cutting forces, a stabilizing system for mechanical processing. If the speed is higher than 430 m/min, the curves associated with the roughness to take the form of increase due to fluctuations associated with high speeds.

2. Enec, M., Serebryakov V.I., Schwarzburg L.E. Influence of composition of the coating of tool inserts by the method of PVD for surface roughness in turning // Technology of mechanical engineering. 2010. No. 8. pp. 25-28.

3. Pronin, A. I., Mylnikov V.V., Chernyshov E.A., Shetulov D.I. Determination of the optimum cutting speed in hard turning using acoustic emission signals // Control. Diagnosis. 2014. No. 4. pp. 40-44.

4. Pronin, A. I., Mylnikov V.V., Chernyshov E.A. The reasons for the low efficiency of the plates of cutting ceramics with hard turning // Materials Science. 2014. No. 5. pp. 13-15.

5. Pronin, A. I., Mylnikov V.V., Shchelkunov, E.B., Vinogradov, S.V. Application of orthogonal Central composite design of experiments to optimize the turning of hardened steel 40X cutting ceramics // Bulletin of engineering. 2016. No. 8. pp. 43-48.

Pronin A.I., Mylnikov V.V., Kondrashkin O.B., Chernyshov E.A., Shetulov D.I. STUDY OF THE INFLUENCE OF SEVERAL FACTORS OF THE TOKAR PROCESSING TO THE FORMATION OF THE ROUGHNESS OF THE PROCESSED SURFACE. International Journal Of Applied And Fundamental Research. – 2017. – № 3 –

URL: www.science-sd.com/471-25284 (06.02.2026).

PDF

PDF