About Us

Executive Editor:Publishing house "Academy of Natural History"

Editorial Board:

Asgarov S. (Azerbaijan), Alakbarov M. (Azerbaijan), Aliev Z. (Azerbaijan), Babayev N. (Uzbekistan), Chiladze G. (Georgia), Datskovsky I. (Israel), Garbuz I. (Moldova), Gleizer S. (Germany), Ershina A. (Kazakhstan), Kobzev D. (Switzerland), Kohl O. (Germany), Ktshanyan M. (Armenia), Lande D. (Ukraine), Ledvanov M. (Russia), Makats V. (Ukraine), Miletic L. (Serbia), Moskovkin V. (Ukraine), Murzagaliyeva A. (Kazakhstan), Novikov A. (Ukraine), Rahimov R. (Uzbekistan), Romanchuk A. (Ukraine), Shamshiev B. (Kyrgyzstan), Usheva M. (Bulgaria), Vasileva M. (Bulgar).

PDF

p. 46-46

PDF

p. 46-46

Traditional methods of getting spinels (solidphase mechanism from oxides of the appropriate metals) usually run with high temperatures and demand long heat treatment which is conditional upon not fast reactions. One of the methods of making such solidphase reactions faster is introduction of small additives of alkali metal halides into reaction environment. Aim of the research is study of infl uence of additive KCl on the process of formation of spinel NiFe 0,8 Cr 1,2 O4.

Material of the given composition was obtained with the help of ceramic technology. At a temperature of 1100 °С of heat treatment the process of formation of spinel structure takes 90 hours.

In the process of ongoing study synthesis of substances was carried from the oxides of nickel (II), chromium (III), iron (III) with the addition of potassium chloride. The starting materials were homogenized in an agate mortar for one hour with ethyl alcohol in the air, pressed into tablets and heat treated for 4–5 hours at a lower temperature. The completeness of spinel formation was controlled by X-ray phase analysis.

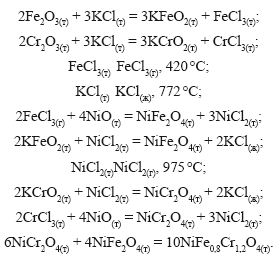

According to information in literature [1], introduction of alkali metals halides into the mixture allows synthesis at lower temperatures. It was marked that the effect from introduction of the additive is decrease with increasing temperature of heat treatment over 800 °С. As a result of the undertaken study it was found that the process of spinel formation at temperature 950–1050 °C is more complete. Explanation of the experimental fact may be given with regard of infl uence of gas phase, formation of which is possible in the course of the following reactions:

In the process of structure formation there were involved both ferric chloride (III) and nickel chloride (II), which is apparently the reason of a more complete reaction of spinel formation at higher temperatures. Formation of gas phase during the reaction takes, apparently, the process from diffusion sphere into kinetic one.

References

- Chervinko A.G. Influence of halogem anions on the process of formation of oxides of zinc ferrite // Chemestry and chemical technology. - 1972. - Т. 15, № 12. - P. 1831-1834.

Talanov V.M., Shabelskaya N.P., Ulianov A.K., Golovina A.G., Reznichenko L.A., Talanov M.V. POSSIBLE INFLUENCE OF POTASSIUM CHLORIDE ADDITIVE ON THE PROCESS OF FORMATION OF SPINEL NIFE 0,8 CR 1,2 O 4. International Journal Of Applied And Fundamental Research. – 2011. – № 2 –

URL: www.science-sd.com/389-23588 (23.02.2026).