About Us

Executive Editor:Publishing house "Academy of Natural History"

Editorial Board:

Asgarov S. (Azerbaijan), Alakbarov M. (Azerbaijan), Aliev Z. (Azerbaijan), Babayev N. (Uzbekistan), Chiladze G. (Georgia), Datskovsky I. (Israel), Garbuz I. (Moldova), Gleizer S. (Germany), Ershina A. (Kazakhstan), Kobzev D. (Switzerland), Kohl O. (Germany), Ktshanyan M. (Armenia), Lande D. (Ukraine), Ledvanov M. (Russia), Makats V. (Ukraine), Miletic L. (Serbia), Moskovkin V. (Ukraine), Murzagaliyeva A. (Kazakhstan), Novikov A. (Ukraine), Rahimov R. (Uzbekistan), Romanchuk A. (Ukraine), Shamshiev B. (Kyrgyzstan), Usheva M. (Bulgaria), Vasileva M. (Bulgar).

PDF

p. 16-18

PDF

p. 16-18

Type metals are manufactured based on the system antimony-lead-tin. Antimony (8-23 %) enters the composition of type metals increasing their hardness and decreasing their shrinkage in cooling. Tin (2-7 %) improves their casting characteristics and eliminates extraordinary fragility of the metal, and lead is the base of any type metal.

There are used several grades of type metals, depending on the composition the metals differ by their melting temperature, hardness and other properties.

However all the type metals must satisfy the following technical requirements:

- to melt at a possible low temperature;

- to have good casting properties, i.e. to be liquid at the casting temperature;

- to have low shrinkage at solidifying;

- not to damage matrixes and parts of the casting mechanism as a result of melted metal chemical effect;

- to have high mechanical strength in solid state;

- the metal losses in repeated castings must be minimal;

- not to be toxic;

- not to contain in its composition scarce and expensive metals, i.e. to be economically acceptable;

- prints cast from a type metal mustn't damage under the action of water, atmospheric conditions, washing matters and in warehousing.

Of all the requirements listed the most important properties defining the type metal quality are casting properties and hardness.

The type metal hardness is one of the most significant operation properties, as the harder is the type metal, the higher is its wear resistance, the higher is the impression resistance of the plate made of this metal.

During the last years the printing industry with mass numbers of copies uses a computer text input or photo-polymer plates, however in printing specific production (reproductions, engravings, etc.) there is still used a type matter, that's why the problem of improving the type metal quality is still urgent.

In some studies [1, 2] there was noted that barium-containing additives effect positively the type metals hardness. A natural barium,-containing matter is barite. It is a mineral presenting barium sulfate (BaS04), it is rather widely spread in nature and is the main barium source in chemistry. In many cases barium in barite is partly substituted by strontium, lead or calcium. Barite possesses high density - 4,3-4,7 g/сm3, its hardness by Moos scale is from 3,0 till 3,5.

Kazakhstan possesses about 23 % of all the world barite resources. In the world practice the main part of barite (about 75 %) is used for drilling oil and gas bore-holes. However during the last years barite is more widely used in other industries. Prospective lines of barite use is cement branch, heavy concretes and ferroalloys producing, etc.

In this work there is studied barite additives effect on the type metals hardness. For studies there were used samples prepared from the existing used type metal (its composition is shown in Table 1). The type metal used after washing was milled and mixed with barium-contai8ning matter which was usually a barite concentrate of the Zhairem deposit, containing about 95 % of pure barite. Barite additives were made over 100 % by mass.

To carry out experiments the barite concentrate was milled till the size 400 mkm (90 %) and combined with the system metal part. As barite tends to burn out, in loading barite was placed in the middle of the crucible, and the melting was carried out in the closed graphite crucible at the temperature 350 °С. In the system melting there took place a melt natural homogenization, and there was no chemical liquation on the ingot body. After the melting the samples were cooled and subjected to studying for hardness and wear resistance.

Their hardness was determined by Brinnel method in accordance with State standard 9012-59 for lead and other alloys. Wear resistance of the alloys obtained was determined with the help of measuring the sample mass changing (SS 23.224-86) by the formula:

![]()

where gei; gii is mass loss for individual tested reference and studied samples, g.

As a reference there was used an analog type metal without barite additives.

To obtain valid results all the measuring was carried out no less than on three doubles, the discrepancy didn't exceed 5 %. The confidential assessment of the results was carried out by the way of comparing to the empiric standard with the significance level Р = 0,98. The assessment of the discrepancy significance between the parameters compared was carried out with the help of Student criterion Р = 0,98.

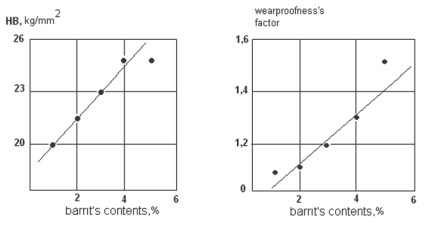

The results of the studies carried out are shown in Table, on the base of which there were built the dependences of hardness and wear resistance factor on barite content in the alloy.

Barite content effect on the alloy properties

|

Sample No |

Alloy composition, % |

Alloy properties |

||||

|

Sn |

Sb |

Pb |

barite |

НВ, kg/mm2 |

Wear resistance factor |

|

|

Reference |

5 |

14,5 |

80, 5 |

- |

19 |

1 |

|

1 |

5 |

14,5 |

80, 5 |

1 |

20 |

1,05 |

|

2 |

5 |

14,5 |

80, 5 |

2 |

22 |

1,05 |

|

3 |

5 |

14,5 |

80, 5 |

3 |

23 |

1,15 |

|

4 |

5 |

14,5 |

80, 5 |

4 |

25 |

1,2 |

|

5 |

5 |

14,5 |

80, 5 |

5 |

25 |

1,2 |

As we can see from the Table and Figure, barite additives increase the alloy hardness and wear resistance about 20 % on the average.

The mechanism of positive effect on the alloy hardness and, consequently, on wear resistance is not still quite clear. However, taking into consideration the diagram antimony-lead-tin, there can be supposed the forming of the triple solid solution alloyed with barium. Partial barium substitution with lead atoms in the solution leads to increasing the friction-induced stress in the lattice, and hardening takes place by the mechanism which is analogous to hardening of alloyed ferrite [4].

Type metal hardness and wear resistance dependence on barite content

In this work there was not analyzed in details barite effect on other important properties of type metals, such as liquidity and tendency to shrinkage. However in visual observation these properties didn't change. All the mold details were not filled completely, shrinkage extent was 0,8 % on the average. This value somewhat exceeds the one indicated in SS 5235-72 (0,7 %). In this connection the further increasing barite additives seems to be inexpedient.

The studies carried out showed the possibility of increasing type metals wear resistance by means of introducing small quantities (1-5 %) of barite additives. This trend seems to be prospective as barite concentrate is rather inexpensive raw material.

Conclusions

1. There has been experimentally proved the possibility to use barite for increasing some properties of type metals.

2. Introducing small quantities (1-5 %) of barite permits to increase 15-20 % type metals hardness and wear resistance.

1. Berezin B.I. Printing production material study. - 2-d edition. - М.: Materialovedeniye, 1972. - 420 p.

2. Tyan V.D., Kubarev A.D., Zhangarayev A.Zh., Kakenov N.K., Dzhasupov А.Т. Complex use of barite ores of Zhairem deposit // J. Complex use of mineral raw materials. - 1982. - №6. - Р. 39.

3. Pankov V.A., Kozhevnikov G.N., Zhauchkov V.I., Lukin S.V., Parfenov А.А. Obtaining barium-containing alloys from barite ores // J. Complex use of mineral raw materials. - 1981. - №11. - Р. 63.

4. Goldstein M.N., Grachyov S.V., Veksler Yu.G. Special steels. - М.: Мtallurgy, 1989.

5. Lokshin E.P., Voskoboinikov N.B. Barium. Barium and its properties. - М.: Nedra, 1996. - 350 p.

Isagulov, Kvon S.S., Malashkevichute, Tulegenova S.N. STUDYING BARITE EFFECT ON SOME PROPERTIES OF TYPE METALS. International Journal Of Applied And Fundamental Research. – 2012. – № 1 –

URL: www.science-sd.com/450-24004 (11.02.2026).