About Us

Executive Editor:Publishing house "Academy of Natural History"

Editorial Board:

Asgarov S. (Azerbaijan), Alakbarov M. (Azerbaijan), Aliev Z. (Azerbaijan), Babayev N. (Uzbekistan), Chiladze G. (Georgia), Datskovsky I. (Israel), Garbuz I. (Moldova), Gleizer S. (Germany), Ershina A. (Kazakhstan), Kobzev D. (Switzerland), Kohl O. (Germany), Ktshanyan M. (Armenia), Lande D. (Ukraine), Ledvanov M. (Russia), Makats V. (Ukraine), Miletic L. (Serbia), Moskovkin V. (Ukraine), Murzagaliyeva A. (Kazakhstan), Novikov A. (Ukraine), Rahimov R. (Uzbekistan), Romanchuk A. (Ukraine), Shamshiev B. (Kyrgyzstan), Usheva M. (Bulgaria), Vasileva M. (Bulgar).

PDF

p. 22-24

PDF

p. 22-24

For the closest future an agglomeration remains one of the main methods of preparing iron-ore material for blast melting. Therefore, efforts of many scientists both in our country and abroad are nowadays aimed for the search of new means of carrying out the agglomeration process. To these means we can refer the agglomeration of iron-ore materials with usage of high-pressure air.

The following problems are studied in the work:

- an impact of separate parameters of caking regime - the pressure of the supercharged air, temperature of its heating, amount of fuel in furnace charge upon the efficiency of the agglomeration facility and quality of the final product;

- comparing the received data with indexes of agglomeration process under vacuum regime of caking.

The research has been carried out on the facility consisting of cylindrical caking bowl and electric air supercharger. Along the pitch of the bowl were placed connecting pipes for thermopair installment, measurement of air pressure above the layer and pressure of the discharged gas above the fire grate.

The furnace charge of the fixed composition was mixed and balled on a plate granulator, the duration of mixing dry and moist charge equaled approximately three minutes. Before the load of furnace charge into the bowl layers of bed with height of 10-15 mm and fineness of 5-10 mm were paced upon the fire grate. The height of furnace charge layer equaled 300 mm. An ignition of furnace charge was carried out under vacuum during 1 minute with coke breeze and wood shaving.

Within the initial period optimal fuel consumption and furnace charge wetness was defined, and as an optimal criterion the vertical caking speed and cold solidity of agglomerate was taken.

Under vacuum agglomeration an optimal content of cox breeze in furnace charge and its moist equaled 3,8 and 6,2 % correspondingly, and under caking with pressed cold air these values were lowered to 3,3 and 4,2 %. The consumption of cox breeze during caking with hot air was altered from 1 to 5 %. The basic capacity of СаО/SiO2 for all agglomerates equaled 0,95.

The prepared cake after its cooling on air was exposed to double dropping from the height of 2 m upon a steel plate. A fraction of +10 mm was considered as a proper agglomerate, fractions 0f 10-5 mm were used as a bed, and fraction of 0-5 mm was returned. The solidity of agglomerate was defined according to the output of fraction of 5-0 mm after its 4-time dropping and according to the barrel of Rubin.

The results of the experiments are provided in Table 1. The analysis of the data testifies for a significant impact of fuel consumption during the caking process upon the indexes of agglomeration process. Thus, under the caking with cold air with pressure of 0,2 MPa the best indexes of efficiency and quality of agglomerate were achieved with fuel consumption of 3,3 %.

With an increase of carbon consumption over the optimal value the output of the valid decreased as a result of the macroporous agglomerate that possessed lower solidity. The specific efficiency of the facility under the cox breeze consumption for caking of 3,3 % equaled 4,46 t/m2 per hour that is 3 times higher than that under vacuum caking. The cold solidity of the agglomerate, caked under pressure was imes higher than that of agglomerate, caked under vacuum. The higher solidity was achieved due to a significant consolidation of the furnace charge layer during the process of caking and receiving of finely porous normally-melted agglomerate. Obviously, during caking under pressure, as well as under vacuum agglomeration, it is necessary to set an optimal carbon consumption for the process.

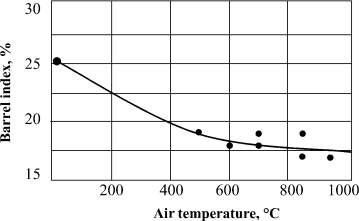

Fig. 1 provides the impact of air temperature and fuel consumption under caking upon the cold solidity of agglomerates. According to the picture data we can see that under the fuel consumption of 1,8 % the solidity of agglomerates, caked under the heated up to 950 °С air is higher than that of agglomerate, caked with cold air. Barrel index of agglomerate decreases correspondingly by 7,0 and 12,0 % (absolute values) compared to agglomeration under pressure of cold air and vacuum caking (barrel index - 30 %). With an increase of air temperature from 500 to 950 °С with fuel consumption of 1,8-2,5 % the agglomerates' solidity styed practically the same.

The results of test cakings with different cox consumption

|

Cox breeze for mass of dry fyrnace charge, % |

Vertical caking speed, |

Caked output, % |

Valid output for the caked mass, % |

Specific |

Fraction output (0-5) mm after dropping, % |

Agglomerate content, % |

|

|

Fegen |

FeO |

||||||

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

|

Agglomerate, received under the temperature and air pressure (20 °С and 0,2 MPa) |

|||||||

|

2,8 |

55,6 |

91,2 |

81,2 |

4,37 |

4,2 |

58,3 |

9,8 |

|

3,3 |

56,1 |

92,3 |

82,0 |

4,46 |

3,8 |

58,2 |

12,9 |

|

4,0 |

54,5 |

92,0 |

81,0 |

4,29 |

3,7 |

59,0 |

16,3 |

|

5,0 |

57,1 |

92,4 |

79,1 |

4,38 |

3,9 |

59,2 |

19,8 |

|

6,0 |

54,5 |

93,7 |

78,6 |

4,16 |

4,0 |

60,1 |

26,6 |

|

Agglomerate, received under the temperature and air pressure (600 °С and 0,2 MPa) |

|||||||

|

1,5 |

47,4 |

90,3 |

88,1 |

3,74 |

3,5 |

58,0 |

5,7 |

|

2,0 |

25,6 |

91,1 |

91,6 |

4,68 |

2,8 |

57,9 |

6,2 |

|

2,5 |

54,5 |

89,5 |

92,3 |

4,87 |

2,6 |

58,6 |

8,6 |

|

3,0 |

54,5 |

90,0 |

91,6 |

4,85 |

2,2 |

58,3 |

10,8 |

|

5,0 |

58,1 |

95,5 |

87,3 |

4,93 |

2,8 |

60,3 |

23,2 |

|

Agglomerate, received under the temperature and air pressure (950 °С and 0,25 MPa) |

|||||||

|

1,5 |

65,2 |

89,8 |

91,8 |

5,82 |

3,0 |

57,6 |

3,4 |

|

1,8 |

63,3 |

89,5 |

91,4 |

5,75 |

2,8 |

58,0 |

4,2 |

|

2,0 |

62,5 |

91,3 |

92,0 |

5,53 |

2,8 |

57,5 |

6,4 |

|

2,5 |

63,8 |

90,2 |

92,2 |

5,72 |

2,7 |

57,8 |

8,8 |

|

3,0 |

61,2 |

91,7 |

91,0 |

5,42 |

2,4 |

57,8 |

12,2 |

|

Agglomerate, received under the temperature and air pressure (1100 mm) |

|||||||

|

3,8 |

20,0 |

84,6 |

73,2 |

1,42 |

11,7 |

57,8 |

13,7 |

The results of test cakings under different pressures

|

Cox breeze for mass of dry fyrnace charge, % |

Vertical |

Caked output, % |

Valid output for the caked mass, % |

Specific |

Fraction output (0-5) mm after dropping, % |

Agglomerate content, % |

|

|

Fegen |

FeO |

||||||

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

|

Agglomerate, received under the temperature of 20 °С and fuel content in furnace charge of 3,3 % |

|||||||

|

0,2 |

30, |

76,1 |

2,21 |

9,8 |

30 |

58,5 |

6,5 |

|

0,5 |

40,5 |

81,5 |

3,21 |

4,3 |

28 |

58,4 |

8,9 |

|

1,0 |

56,1 |

82,0 |

4,46 |

3,8 |

25 |

58,2 |

12,9 |

|

1,5 |

64,5 |

82,0 |

5,13 |

4,0 |

26 |

58,7 |

12,5 |

|

2,0 |

85,7 |

82,5 |

6,87 |

3,6 |

25 |

58,5 |

13,3 |

|

Agglomerate, received under the temperature of 600 °С and fuel content in furnace charge of 2,2 % |

|||||||

|

0,5 |

40,0 |

85,2 |

87,8 |

3,49 |

3,2 |

58,5 |

5,2 |

|

1,0 |

54,5 |

91,2 |

88,6 |

4,70 |

3,3 |

59,0 |

7,1 |

|

1,5 |

62,5 |

88,7 |

90,5 |

5,49 |

2,7 |

58,1 |

8,3 |

|

2,0 |

80,0 |

87,9 |

91,6 |

7,12 |

2,9 |

58,3 |

8,4 |

|

2,0 |

80,0 |

92,6 |

88,3 |

6,86 |

3,5 |

58,0 |

9,3 |

Fig. 1. The dependence of barrel index of an agglomerate solidity upon the air temperature with different fuel content:

Fuel content under temperatures:

20 °С - 3,3; 500 °С - 2,5; 600 °С - 2,2; 700 °С - 2,2; 850 °С - 2,0; 950 °С - 1,8

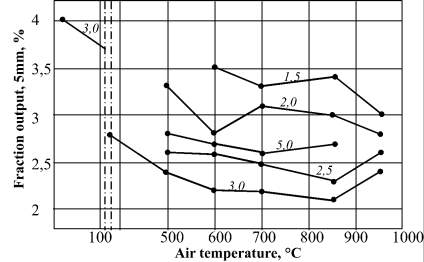

The greatest impact upon the cold solidity of agglomerates carried the fuel consumption for caking. Fig. 2 provides the dependence of fraction output (-5) mm after 4-time dropping depending on fuel consumption under air temperatures for caking of 500-950 °С. With an alteration of fuel consumption for caking from 1,5 to 3 % an increase in agglomerate solidity was observed, while the further increase in fuel consumption up to 5 % led to a decrease in agglomerate solidity. A characteristic of agglomerate solidity is also the fraction output - 5 mm and the output of the valid after caking. As shows the picture, an optimal fuel consumption for the valid output equals 2,5 % for all air temperatures, besides, for low fuel consumptions (lower than 2,5 % along with an increase in air temperature an output of valid agglomerate increases). With fuel consumptions over 2,5 % an impact of temperature weakens.

Fig. 2. Dependence of an agglomerate solidity upon the air temperature with different fuel content:

Digits by curves - fuel consumption under caking, %

According to the provided data we can suppose that the best agglomerate according to cold solidity with caking with air, heated up to 500-700 °C was received with fuel consumption of 2,5 %. An increase in pressure under caking with hot (600 °C) air allowed us not only to increase efficiency, but also to improve the quality of the received agglomerate. With pressure increase from 0,05 to 0,2 MPa the output of valid agglomerate increased from 87,5 to 91,6 %.

Isin D.K., Isagulov A.Z., Oryngozhina S.E., Isin B.D., Zholdubayeva Z.D. AN IMPACT OF SOME FACTORS UPON THE PROCESS OF CAKING OF IRON-ORE MATERIAL. International Journal Of Applied And Fundamental Research. – 2012. – № 1 –

URL: www.science-sd.com/450-24006 (11.02.2026).