About Us

Executive Editor:Publishing house "Academy of Natural History"

Editorial Board:

Asgarov S. (Azerbaijan), Alakbarov M. (Azerbaijan), Aliev Z. (Azerbaijan), Babayev N. (Uzbekistan), Chiladze G. (Georgia), Datskovsky I. (Israel), Garbuz I. (Moldova), Gleizer S. (Germany), Ershina A. (Kazakhstan), Kobzev D. (Switzerland), Kohl O. (Germany), Ktshanyan M. (Armenia), Lande D. (Ukraine), Ledvanov M. (Russia), Makats V. (Ukraine), Miletic L. (Serbia), Moskovkin V. (Ukraine), Murzagaliyeva A. (Kazakhstan), Novikov A. (Ukraine), Rahimov R. (Uzbekistan), Romanchuk A. (Ukraine), Shamshiev B. (Kyrgyzstan), Usheva M. (Bulgaria), Vasileva M. (Bulgar).

Engineering

Values, defined through the approximation tables, depend on three parameters: angle extent of greasing layer or covering angle (120°, 180°), relative concentricity χ (0,4 ÷ 0,99), and relation between piston head length and piston diameter l/d (0,4 ÷ 1,5). The studied bearings work in terms of low angle spike speed and low oil viscosity.

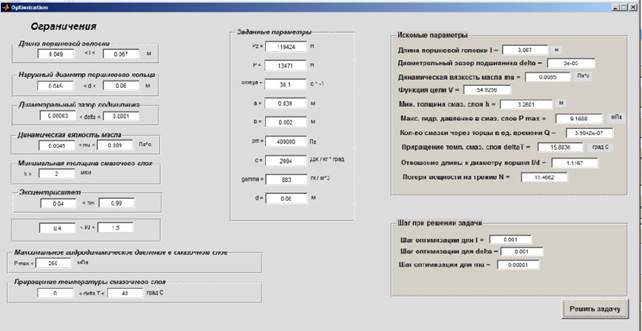

Before the calculations we have to input the set (constant) parameters: grease supply pressure; specific oil heat capacity; specific ill mass; piston diameter. The following limitations are introduced: piston head length l; diametral bearing gap D; dynamic oil viscosity m; maximum hydrodynamic pressure Pmax; evaluation of dynamic bearing load in terms of semi-liquid and limiting friction Pz; increase in greasing layer temperature DT; 0 concentricityа c ; relations between piston head and piston diameter l/d.

Searched parameters are: l – piston head length; D - diametral bearing gap; m - dynamic oil viscosity.

Optimization of bearing parameters is carried out via method of gradient descent [2]:

The program interface is provided in picture 1.

Picture 1.

The program allows us to calculate optimal bearing size with the set limitations and initial parameters.

2. V.I. Surkin, B.V. Kurchatov Greasing of tractor engines (monograph). –Chelyabinsk, 2009, 226 p.

Zaviyalov O.G. SOLVING THE PROBLEM OF OPTIMIZING PISTON CAM SLID BEARING OF TRACTOR ENGINE. International Journal Of Applied And Fundamental Research. – 2013. – № 1 –

URL: www.science-sd.com/452-24473 (11.02.2026).

PDF

PDF