About Us

Executive Editor:Publishing house "Academy of Natural History"

Editorial Board:

Asgarov S. (Azerbaijan), Alakbarov M. (Azerbaijan), Aliev Z. (Azerbaijan), Babayev N. (Uzbekistan), Chiladze G. (Georgia), Datskovsky I. (Israel), Garbuz I. (Moldova), Gleizer S. (Germany), Ershina A. (Kazakhstan), Kobzev D. (Switzerland), Kohl O. (Germany), Ktshanyan M. (Armenia), Lande D. (Ukraine), Ledvanov M. (Russia), Makats V. (Ukraine), Miletic L. (Serbia), Moskovkin V. (Ukraine), Murzagaliyeva A. (Kazakhstan), Novikov A. (Ukraine), Rahimov R. (Uzbekistan), Romanchuk A. (Ukraine), Shamshiev B. (Kyrgyzstan), Usheva M. (Bulgaria), Vasileva M. (Bulgar).

Materials of the conference "EDUCATION AND SCIENCE WITHOUT BORDERS"

Forging on radial – forging machine has a number of advantages: high accuracy of the forgings, the ability to achieve high total reduction without damage, higher performance compared with traditional methods of forging: on presses and hammers, etc. Along with these advantages, this process has a number of features: metal flow is characterized by a pronounced movement in the longitudinal direction and slowly - in the radial. Also, for a single compression is relatively small deformation of the metal. Together, these features create a stress - strain state in which fine worked out surface layers of the metal, but in the central region can virtually absent plastic deformation. Thus there is insufficient study of the axial forgings, without destroying the structure of cast metal. [1]

Circumvent such a feature of the process in various ways, for example by increasing the reduction per pass. However, when forging of high alloy steel, this approach is undesirable because of their low ductility, may cause defects such as cracks, tears, etc. Another solution is to use a combination of certain strain - speed parameters of the forging process with a particular form of the working tool. Thus there is an increased flow of metal to the center of forging, which causes stress in the axial zone, exceeding the yield strength, but not exceeding the tensile strength of the metal to provide a plastic deformation and, as a consequence destroying cast structure without formation of defects.

To test this theory has been used simulation of the forging operation at the RFM in an engineering software DEFORM-3D, based on the use of finite element method Was studied two variant forms of the dies: basic and modified.

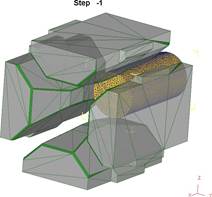

Simulation was carried out according to the following general scheme. First models of dies and billet were created in SolidWorks and then united in assembly. After the assembly were imported into DEFORM-3D Multiple Operations. Curve yield strength of the workpiece assigned by superalloy CrNi56WMoTiAl (EP199) [2]. Workpiece was divided into finite - element mesh of 35,000 elements. The heating temperature of the workpiece was 1150°C. Then movement of the tool and workpiece was specified, also were set the boundary conditions of friction and heat transfer, stopping criteria, and run the calculation. Initial assembly, imported into DEFORM-3D, is shown in Figure 1.

Figure 1. Initial assembly

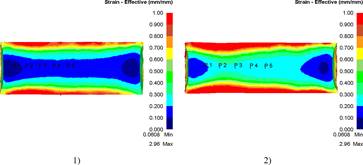

After complete calculating the obtained data were analyzed in the DEFORM–3D Postprocessor. Model of the forging was applied to longitudinal axial slice for assessing the internal stress - strain state. For a more accurate estimate was additionally set a number of points at which stress–strain state was also determined. The points were located in the axial zone at different distances from the end of the forging, their locations are shown in Figure 2.

Figure 2. Location of control points

Distribution of effective strain after forging using base dies shown in Figure 3.1., using modified dies - in Figure 3.2. As can be seen, using modified dies allow to create higher strain in the axial region of the forging, at the same degree of relative deformation.

Figure 3. Distribution of effective strain

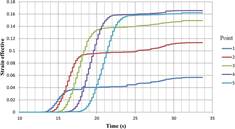

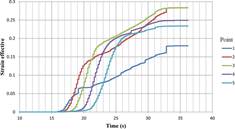

Data from the control points are shown in Figures 4 and 5 leads to the conclusion that the values of effective strain in the axial deformation zone by using a modified form of the dies are 1.5-2 times higher than the base form.

Figure 4. Values in the control points at the initial settings

Figure 5. Values in the control points at the modified settings

Conclusions

According to the results of simulation, it can be concluded that the use of certain deformation - speed parameters of the forging process in conjunction with the form of the working tool allows to destroy the structure of cast metal in forging for radial - forging machines across the entire cross section of the forging, thereby improving the quality of products from high-strength steels and alloys.

2. Resistance to plastic deformation of metals and alloys. Poluhin P.I., Gong G.Y., Galkin A.M. M., Metallurgiya, 1976. - 488 p.

Antoshchenkov Yu.M., Taupek I.M. THE POSSIBILITY OF OBTAINING HIGH-QUALITY FORGINGS FROM HIGH-ALLOY STEELS AND ALLOYS USING RADIAL – FORGING MACHINES. International Journal Of Applied And Fundamental Research. – 2013. – № 2 –

URL: www.science-sd.com/455-24072 (24.02.2026).

PDF

PDF