About Us

Executive Editor:Publishing house "Academy of Natural History"

Editorial Board:

Asgarov S. (Azerbaijan), Alakbarov M. (Azerbaijan), Aliev Z. (Azerbaijan), Babayev N. (Uzbekistan), Chiladze G. (Georgia), Datskovsky I. (Israel), Garbuz I. (Moldova), Gleizer S. (Germany), Ershina A. (Kazakhstan), Kobzev D. (Switzerland), Kohl O. (Germany), Ktshanyan M. (Armenia), Lande D. (Ukraine), Ledvanov M. (Russia), Makats V. (Ukraine), Miletic L. (Serbia), Moskovkin V. (Ukraine), Murzagaliyeva A. (Kazakhstan), Novikov A. (Ukraine), Rahimov R. (Uzbekistan), Romanchuk A. (Ukraine), Shamshiev B. (Kyrgyzstan), Usheva M. (Bulgaria), Vasileva M. (Bulgar).

Materials of the conference "EDUCATION AND SCIENCE WITHOUT BORDERS"

Research objective: to analyze the effect modes SPT, and create a mathematical model of microstructure characteristics depending on the modes SPT. For the studied microstructural characteristics taken following parameters: diameter of grain - dm , its area - S, number of grains per unit of area - N and surface hardness, the independent factors were: the energy of the impact - E, j (X1), preliminary statistical force - Fst, kN (x2), the diameter and width of roller - Dp and b, mm (X3,X4), the depth of hardening - h, mm (X5) (table. 1)

Table 1

|

Factors |

Levels |

||

|

- |

0 |

+ |

|

|

Х1 |

150 |

250 |

350 |

|

Х2 |

20 |

30 |

40 |

|

Х3 |

10 |

15 |

20 |

|

Х4 |

15 |

25 |

35 |

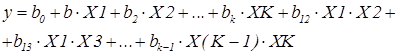

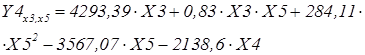

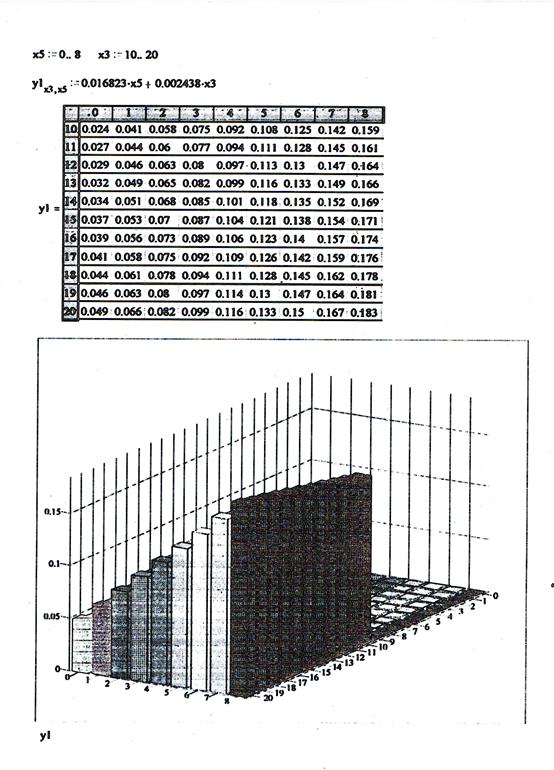

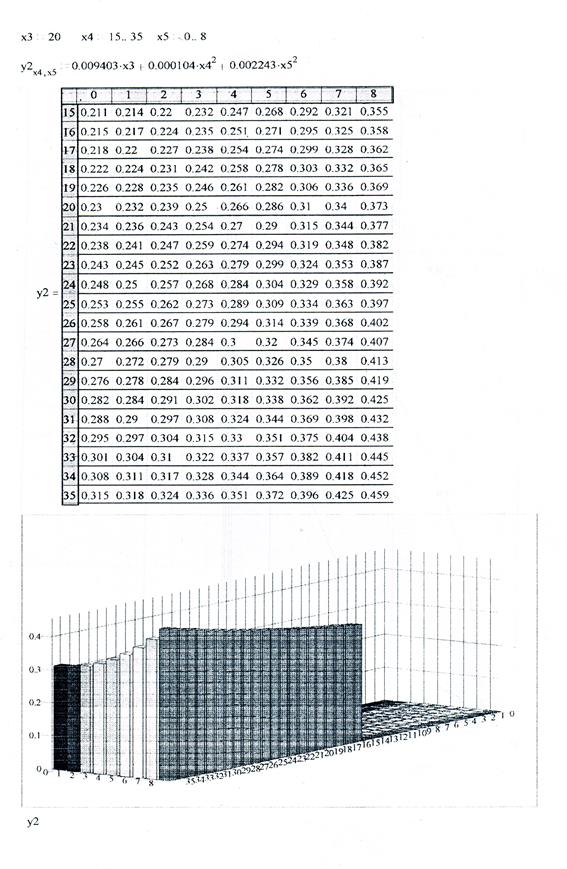

Necessary data the results of the experiment are given in the form of a planning matrix. Using the program for data processing in Statistica 5.1 the company StatSoft Inc. We make the regression equation in the form:

Defining the regression coefficients bO, b1, ... bK, we obtain the following dependencies:

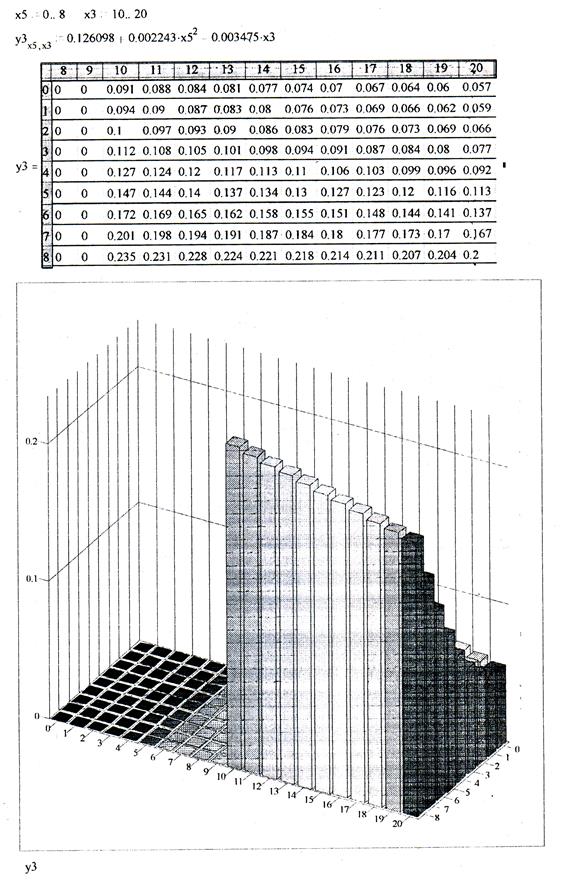

When X3=20, X4=15, X5=0...8

![]()

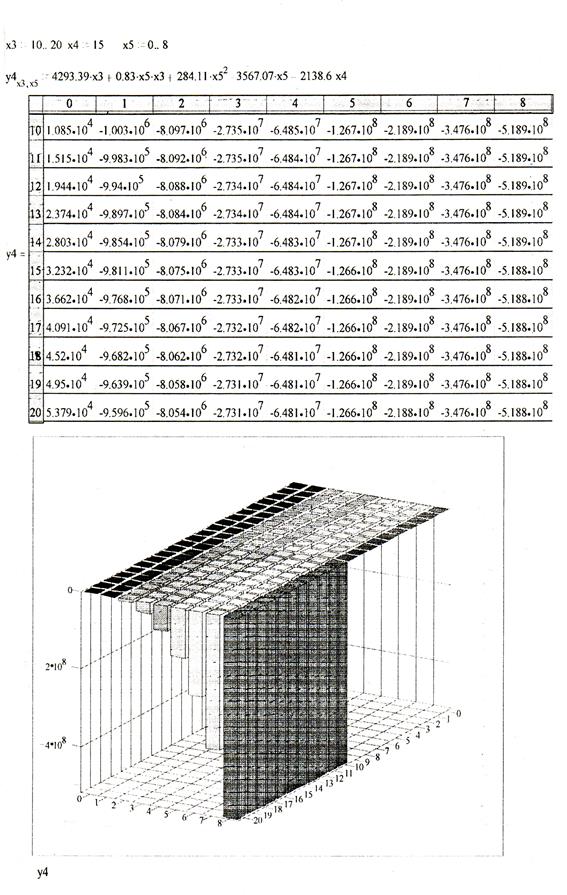

when X3=10...20 X4=0...8

![]()

when X3=10...20, X5=0

![]()

when X3=10...20, X4=15, X5=0...8

The results of calculations and the obtained equations are presented depending on pictures 1-4. A number of summands in the model reflect the impact of individual factors, and mixed interaction effects: impact energy, static component of the load, the geometric parameters of the indenter and the depth of the hardened layer. From a mathematical model shows that the most complex nature of the dependence of grain size for steel 110G13L on the diameter of the indenter. Studies also indicate the need for optimization this parameter. Thus, using a mathematical model was found that most small grains fixed on the surface of samples of steel 110G13L, hardened SPT.

Testing the significance of the coefficients was performed by student's criterion: S{bj} = 2,57, at a significance level of 0.05, confidence interval Δbj =2,5; S{b} = 1,05. Largest regression coefficient conclude that the most significant factor is the diameter of the roller when processing CIO, the variance of the reproducibility of results S2(y) is 0,28, the variance of the adequacy of ![]() =1,0,

=1,0, ![]()

![]() . Consequently, the model is adequate. Thus we obtain adequate model for which the level of significance is equal to 0.05.

. Consequently, the model is adequate. Thus we obtain adequate model for which the level of significance is equal to 0.05.

Studies have shown that cause hardening of the HMS when static-pulse processing is crushing corns of austenita in small blocks and blocking the slip planes that provides a significant increase in microhardness and durability.

Mathematical model of the quantitative characteristics of the microstructure of steel 110G13L, which enabled to evaluate the significance of the modes of the static-pulse hardening.

Conclusions: as a result of metallographic research of samples of steel 110G13L, hardened, ICN, in terms of production, the analysis of influence of modes of SPT on the main characteristics of the microstructure. As a result of the implementation of full factorial experiment 24 and processing of data in the packet Statistics 5.1 the company StatSoft Inc. mathematical model of microstructure characteristics depending on the modes SPT, which is represented by a polynomial of the second degree.

Microstructural study confirmed the results of tests on durability, microhardness and mechanical characteristics of the samples from the HMS, hardened SPT in production conditions.

Picture 1.

Picture 2.

Picture 3.

Picture 4.

2. Kokoreva O.G. Study of parameters of quality of the surface layer when handling static-pulse methods. sat scientific papers of International scientific-practical conference «Science, education, society: challenges and prospects of development», Tambov, 2013, pp. 79-81.

3. Y.P. Adler and others. Planning of the experiment in search for optimal conditions. M: Nauka, 1971, p. 283.

4. Lazutkin A.G., Kokoreva O.G. Hardening static-pulse processing. New materials and technologies in machine building and instrument engineering: Materials of the scientific-tehn. proc. Penza, 1996, pp. 26-31.

5. Soloviev D.L. etc. Hardening of heavy-loaded parts by the method of static-impulse electrical FPD. STIN, 2002, no.5, pp. 13-15.

6. Kirichek A.V., Kokorev O.G. Hardening of heavy-duty surfaces crosses turnouts. Status of development prospects of the road complex: Sat. scientific articles. Vol. 3. Bryansk: BGITA, 2001, pp. 39-41.

Kokoreva Olga Grigoryevna Modeling of the characteristics of the microstructure of the surface with strengthening of static-pulse treatment. International Journal Of Applied And Fundamental Research. – 2013. – № 2 –

URL: www.science-sd.com/455-24168 (28.02.2026).

PDF

PDF