About Us

Executive Editor:Publishing house "Academy of Natural History"

Editorial Board:

Asgarov S. (Azerbaijan), Alakbarov M. (Azerbaijan), Aliev Z. (Azerbaijan), Babayev N. (Uzbekistan), Chiladze G. (Georgia), Datskovsky I. (Israel), Garbuz I. (Moldova), Gleizer S. (Germany), Ershina A. (Kazakhstan), Kobzev D. (Switzerland), Kohl O. (Germany), Ktshanyan M. (Armenia), Lande D. (Ukraine), Ledvanov M. (Russia), Makats V. (Ukraine), Miletic L. (Serbia), Moskovkin V. (Ukraine), Murzagaliyeva A. (Kazakhstan), Novikov A. (Ukraine), Rahimov R. (Uzbekistan), Romanchuk A. (Ukraine), Shamshiev B. (Kyrgyzstan), Usheva M. (Bulgaria), Vasileva M. (Bulgar).

Materials of the conference "EDUCATION AND SCIENCE WITHOUT BORDERS"

The Abstract:

The formation mechanism of the dispersing efforts in the ferro-particles’ magneto – liquefied layer of the electromagnetic mechano-activators (EMMA) has been revealed. The force interaction dependence between the grinding elements from the structure group deformation angle from the ferro-spheres in the instruments’ working volumes has been presented and analyzed. It has been found, that the structural models deformation angle from the ferro-elements and its value is characterized the organization and the structure group destruction process, and it is determined the power and the energy characteristics of the electromagnetic mechano-activators.

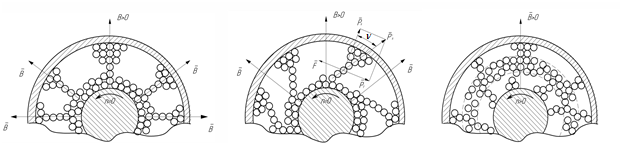

So, the EMMA operation principle is based on the energy conversion of the constant electromagnetic field by its sign into the kinetic energy of the working bodies’ motion (Fig.1) with the subsequent transmission and the partial accumulation of this energy in the material being processed [1,2,3].

a b c

Fig.1. The «sliding layer» organization in the EMMA: a – the structural imaging formation from the ferro-magnetic elements; b – the force interaction between the ferro-magnetic elements; с – the sliding layer formation. B – the magnetic field induction; n – the rotation frequency of the movable cylinder; F – the interaction forces between the ferro-magnetic elements; ![]() – the tangential shear force;

– the tangential shear force; ![]() – the deformation angle of the structural imaging from the ferro-elements.

– the deformation angle of the structural imaging from the ferro-elements.

The energy-intensive nature of the dispersing forces in the shock, the shock-wear, and the abrading modes is resulted in the structural defects accumulation in the material’s grains, the surface curvature increasing, the phase transformations, and even the crystals’ amorphization, which is affected upon their chemical activity [1]. The mechano-activation efficiency is defined in the EMMA by the accumulated quality of the energy processed material, and it, moreover, is depended on the difference in the rates of the defects accumulation in the material, and their disappearance.

As a result of the theoretical and experimental studies [1,2,3,4,5] it has been found, that the EMMA can be considered, as the power amplifier, having allowed you to be transferred the substantial largest energy, by its size, to the magneto-liquefied layer of the working elements (e.g. the ferro-bodies) with the low energy consumption to be created the magnetic field (e.g. up to 30 Wt) and its regulation in the wide – range of the values. For all this, the efficient physical and the mechanical processes control in the layer of the working elements to be ensured the uniform distribution of the mechanical power transmission into the processing environment is practically provided the inequality carrying out [1,4]:

![]() , (1)

, (1)

where ![]() the current power in the control winding (CW);

the current power in the control winding (CW); ![]() the minimum value of the current power in (CW), at which the structural groups from ferro-bodies are being created;

the minimum value of the current power in (CW), at which the structural groups from ferro-bodies are being created; ![]() – the induction in the device cabinet;

– the induction in the device cabinet; ![]() – the radii, respectively, of the inner and outer cylinders, having restricted the device working volume;

– the radii, respectively, of the inner and outer cylinders, having restricted the device working volume; ![]() –the minimum thickness of the device cabinet;

–the minimum thickness of the device cabinet; ![]() – the magnetic permeability of the working volume;

– the magnetic permeability of the working volume; ![]() – the height of the device cabinet;

– the height of the device cabinet; ![]() – the number of the CW turns.

– the number of the CW turns.

The increase in strength and number of the shock impacts upon the final product is occurred during the surfaces’ offset acceleration, having limited the EMMA working volume. For all this, it is necessary the centrifugal force action to be compensated for the м.д.с. control winding (e.g. or the windings) [1,5]:

w = 0,16![]() , (2)

, (2)

where K – the coefficient, having characterized the compensated centrifugal force value, by means of the control windings м.д.с. increasing; F – the adhesion force between the ferro-spheres and the inner cylinder surface; G – the ferro-sphere mass.

The force interaction ![]() in the contact system from the two working elements of the spherical form by the radius

in the contact system from the two working elements of the spherical form by the radius ![]() and the magnetic permeability

and the magnetic permeability ![]() in the magnetic field of the strength

in the magnetic field of the strength ![]() and the moment of the forces

and the moment of the forces ![]() interaction of the field with the working bodies system of the magneto-liquefied layer have already been defined by the expressions [1,3]:

interaction of the field with the working bodies system of the magneto-liquefied layer have already been defined by the expressions [1,3]:

![]()

![]() ; (3)

; (3)

![]()

![]()

![]()

![]() . (4)

. (4)

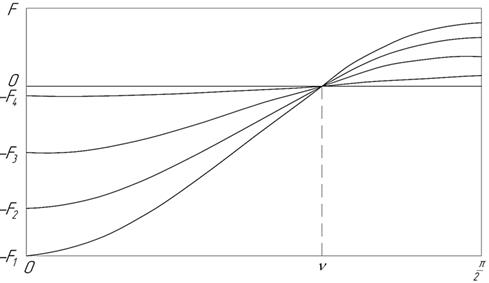

The angle ![]() is the deformation angle of the structural models from the ferro-elements and its value, having defined the force between all these elements, it, moreover, is described and characterized the organizing and destruction process of the structural group (Fig.1). So, the dependence of the force interaction between the working bodies in the magneto-liquefied layer from the deformation angle of the structural models from the ferro-spheres has been presented in the Fig.2.

is the deformation angle of the structural models from the ferro-elements and its value, having defined the force between all these elements, it, moreover, is described and characterized the organizing and destruction process of the structural group (Fig.1). So, the dependence of the force interaction between the working bodies in the magneto-liquefied layer from the deformation angle of the structural models from the ferro-spheres has been presented in the Fig.2.

Fig.2. The Qualitative Dependence of the Force Interaction ![]() between the Grinding Spheres from the Deformation Angle

between the Grinding Spheres from the Deformation Angle ![]() of the Structural Group.

of the Structural Group.

If ![]() =0, when the line, having connected the ferro-bodies’ centers, is paralleled to the tension vector of the unperturbed magnetic field, we have:

=0, when the line, having connected the ferro-bodies’ centers, is paralleled to the tension vector of the unperturbed magnetic field, we have:

![]()

![]()

![]() . (5)

. (5)

So, the minus sign before the formula is indicated the fact, that the attraction is occurred before the spheres. For all this, the ferro-spheres (e.g. the working bodies) are organized into the stable structures with the maximum force interaction between themselves and the surfaces, having limited the EMMA working volume. By moving all these surfaces, the structures are being deformed, and the angle ![]() is being increased, which is reduced the force interaction between the device’s working bodies. Upon reaching the critical deformation angle

is being increased, which is reduced the force interaction between the device’s working bodies. Upon reaching the critical deformation angle ![]() =

=![]()

![]() , the force

, the force ![]()

![]() The angle, at which the working bodies’ attraction is practically replaced by their repulsion, is defined by the following expression:

The angle, at which the working bodies’ attraction is practically replaced by their repulsion, is defined by the following expression:

![]()

![]()

![]() . (6)

. (6)

At ![]()

![]() , i.e., when the line, having connected the working bodies’ centers, is perpendicular to the vector of the field tension, the purposeful re-orientation of the working bodies is taken its place in the EMMA volume, with the energy-intensive multi-point creation of the force contacts between all these elements through the processed material layer. For all this, the uniform distributions are provided the mechanical energy transmission into the processing environment. Thus, the interaction force is practically determined by the following expression:

, i.e., when the line, having connected the working bodies’ centers, is perpendicular to the vector of the field tension, the purposeful re-orientation of the working bodies is taken its place in the EMMA volume, with the energy-intensive multi-point creation of the force contacts between all these elements through the processed material layer. For all this, the uniform distributions are provided the mechanical energy transmission into the processing environment. Thus, the interaction force is practically determined by the following expression:

![]()

![]()

![]() . (7)

. (7)

So, the force interaction between the ferro-spheres in the structural groups’ basis is defined by the mirror images method.

At ![]() =0 and

=0 and ![]()

![]() the moments of the interaction forces of the ferro-spheres are

the moments of the interaction forces of the ferro-spheres are ![]() . The case of the balance

. The case of the balance ![]() =0 is the stable one,

=0 is the stable one, ![]()

![]() – is unstable.

– is unstable.

The use validity of the mathematical model has been confirmed by the results of the experimental studies of the АПК electro–technological processes on the models, the experimental sample (e.g. the RF patent № 1457881) and the development of industrial EMMA design (e.g. the RF patent № 2007094, the certificate of the RF for the utility model № 769) [7,8,9]. Thus, it has been determined, that the energy use of the constant by its sign and regulated by the electro – magnetic field magnitude in the processes of the technological processes activation is allowed to be created the easily – manageable energy – intensive mechanical stresses and impacts by the most economic way, it, moreover, is ensured the uniform transmission of the mechanical energy into the processing environment, and also it is allowed to be carried out the adjustable two – way relationship and its interrelation in the apparatus – technological production systems [1].

2. Bezzubtzeva M.M., Volkov V.S., Zubkov V.V., “The Devices’ Study with Magneto – Liquefied Layer”. // «The Basic Researches», 2013. – № 6., Part 2., p.p. 258 – 262;

3. Bezzubtzeva M.M., Volkov V.S., “The Applied Theory of the Electromagnetic Method of Mechanical Activation”. // «The Proceedings of the International Academy of Agricultural Education». 2013, № 16., Volume 3., p.p. 93 – 96;

4. Bezzubtzeva M.M., Volkov V.S., “The Modes Study of Electromagnetic Mechano – Activators Operation”. // «The Successes of Modern Natural History», 2012. – № 8. – p.p. 109 – 110;

5. Bezzubtzeva M.M., Volkov V.S., “The Providing Conditions of Milling Process Control Products in Electromagnetic Mechano – Activators”. // «The International Journal of Applied and Basic Researches», 2012. – № 7. – p.p. 93 – 94;

6. Bezzubtzeva M.M., “The Energy – Efficient Method of Electromagnetic Activation”. // «The International Journal of Experimental Education»", 2012, – № 5. – p.p. 92 – 93;

7. The RF Patent № 1457881, 03.12.1993;

8. The RF Patent № 2007094, 15.02.1994;

9. The Certificate of the Russian Federation for a Utility Model № 769, 16.09.1995.

Bezzubtzeva M.M., Volkov V.S., Gubarev V.N. THE PHYSICAL AND MECHANICAL PROCESSES STUDY IN FERRO-BODIES’

MAGNETO – LIQUEFIED LAYER OF ELECTROMAGNETIC MECHANO – ACTIVATORS (EMMA) . International Journal Of Applied And Fundamental Research. – 2013. – № 2 –

URL: www.science-sd.com/455-24425 (24.02.2026).

PDF

PDF