About Us

Executive Editor:Publishing house "Academy of Natural History"

Editorial Board:

Asgarov S. (Azerbaijan), Alakbarov M. (Azerbaijan), Aliev Z. (Azerbaijan), Babayev N. (Uzbekistan), Chiladze G. (Georgia), Datskovsky I. (Israel), Garbuz I. (Moldova), Gleizer S. (Germany), Ershina A. (Kazakhstan), Kobzev D. (Switzerland), Kohl O. (Germany), Ktshanyan M. (Armenia), Lande D. (Ukraine), Ledvanov M. (Russia), Makats V. (Ukraine), Miletic L. (Serbia), Moskovkin V. (Ukraine), Murzagaliyeva A. (Kazakhstan), Novikov A. (Ukraine), Rahimov R. (Uzbekistan), Romanchuk A. (Ukraine), Shamshiev B. (Kyrgyzstan), Usheva M. (Bulgaria), Vasileva M. (Bulgar).

For realization of technology of digital prototypes, in our opinion, the most suitable CAD Autodesk Inventor [1]. With its help it was possible to design a variety of technical objects, determination of strength properties of mechanical systems and their detailed visualization. Moreover, the possibilities of virtual solid modeling are not limited to: any material, neither the size nor the structural composition. In this material presents the experience and results of modeling of engineering products used in conducting training sessions and performing scientific research on the analysis of regularities of transformation of mechanical motion [2,3].

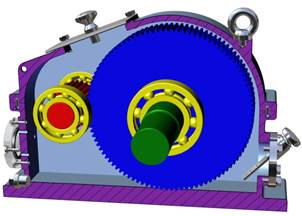

Figure 1 (and next) presents the image of a solid model cylindrical one-stage reductor, developed by us (a - the general view of the longitudinal section; b - a view of the inside device). For educational purposes and is implemented by the so-called paradoxical concept design - application in the structure of the virtual solid-state digital model obviously incompatible real product components: the ring bolt and lifting fixture, the oil-level indicator rod type and in the form of a transparent window.

а b

Fig. 1

Figure 2 presents the image of a solid model of the electromechanical drive in the form of technical illustrations with explanatory and cut reductor.

Fig. 2

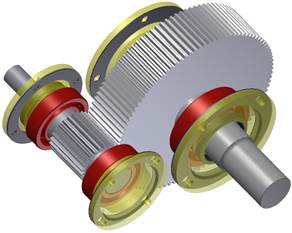

Figure 3 presents the image of a solid model gear in the form of a technical illustration (a) and exploded with the specification of (b).

а b

Fig. 3

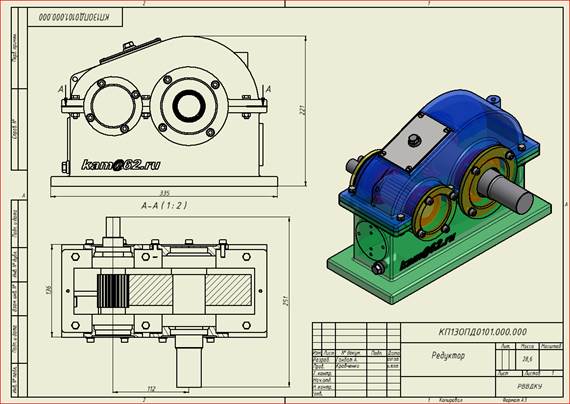

Figure 4 presents the image of the design document - the general view drawing of the reductor, which is produced in semi-automatic mode on the basis of the created virtual model.

Fig. 4

Moreover, the number and complexity of species and cuts has no system no value: it "sees" virtual three-dimensional image of the product.

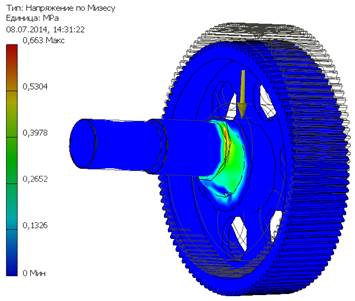

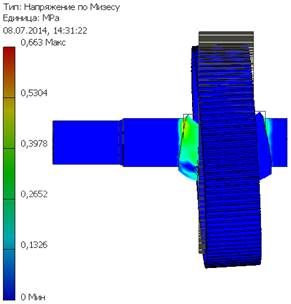

Figure 5 shows the result of the load from the action of the radial force wheels on the shaft (Fig. 5,a). Moreover, the system is so adequately reflects all the nuances of deformation of parts of the mechanism that you can easily find the errors in the design of this assembly. So in Fig. 5,b that during deformation under load gear shifting from initial vertical position.

а b

Fig. 5

A detailed analysis of the relative position of parts (the wheel and shaft) confirms the hypothesis about non-compliance with the conditions of strict symmetry of the placement of the wheel relative to the supporting journals shaft and the disturbance of the geometry of gearings, which, in turn, may lead to a change in the set of kinematics gear teeth up to jamming. Thus, the system allows to avoid design errors in its initial stages.

We present in this paper the concept of a paradoxical design involves programmable making the wrong technical solutions (paradoxes), and the learner is offered by CAD them to detect, eliminate, and to present a solution to this engineering (technical) problem. Subject-shaped technical thinking of students in the context of three-dimensional solid modeling is developing most dynamically and contributes to sustainable development of required competencies presented to the specialist, responsible for the operation of modern machinery.

2. Кравченко А.М., Кравчук Н.В. Информационные технологии в инженерном образовании: монография. – Рязань, РВАИ, 2008;

3. Бышов Н.В., Кравченко А.М., Борычев С.Н. и др. Основы инженерного проектирования: монография. – Рязань, РГАТУ, 2011.

Kravchenko A.M. THE PARADOXICAL CONCEPT OF DESIGN IN THE ANNEX TO THE TECHNOLOGY OF DIGITAL PROTOTYPES. International Journal Of Applied And Fundamental Research. – 2014. – № 2 –

URL: www.science-sd.com/457-24559 (15.02.2026).

PDF

PDF