About Us

Executive Editor:Publishing house "Academy of Natural History"

Editorial Board:

Asgarov S. (Azerbaijan), Alakbarov M. (Azerbaijan), Aliev Z. (Azerbaijan), Babayev N. (Uzbekistan), Chiladze G. (Georgia), Datskovsky I. (Israel), Garbuz I. (Moldova), Gleizer S. (Germany), Ershina A. (Kazakhstan), Kobzev D. (Switzerland), Kohl O. (Germany), Ktshanyan M. (Armenia), Lande D. (Ukraine), Ledvanov M. (Russia), Makats V. (Ukraine), Miletic L. (Serbia), Moskovkin V. (Ukraine), Murzagaliyeva A. (Kazakhstan), Novikov A. (Ukraine), Rahimov R. (Uzbekistan), Romanchuk A. (Ukraine), Shamshiev B. (Kyrgyzstan), Usheva M. (Bulgaria), Vasileva M. (Bulgar).

The Key words: gold, leaching, extraction, pulp density, cyanide concentration.

The Introduction.

In the explored and proven gold reserves, Kazakhstan is ranked the 10-th place in the world (e.g. the 3-rd place in the CIS), in mining – 13,4 t. – the 25-th place (e.g. the 4-th place in the CIS). According to the «Tauken – Samruk» National State Company data, the mineral and resource base of the gold fields and deposits in Kazakhstan is presented by the 287 ones (e.g. 38 of them – the gold – bearing complex ones, 60% – in fact, the gold ore ones, and 2% – the alluvial ones). So, in the industrial development (e.g. the licences have already been issued), today, there are more, than one hundred gold fields and deposits [1].

In comparison with the world gold ore mineral and resource base, in Kazakhstan a more significant role, as in the reserves, well as in the mining, the complex ores fields and deposits are being played. The fields and deposits of the copper and porphyritic types of the ores are of much smaller specific proportion. According to the reserves and quality level, the main gold ore fields and deposits in Kazakhstan are comparables with the fields deposits of the foreign countries, and, in principle, could be provided a higher level of the gold production in the country. At the same time, at the unfavorable world conjuncture of the gold, the presentation more stringent requirements for the qualitative and quantitative parameters of the individual fields and deposits and for the mineral and resource base, as a whole, is become inevitable. Under the world prices at the end of the century conditions, the total number of the competitive reserves is made up, approximately, 75% of counted on the reserves balance, proper, gold ore native fields and deposits and 27% of the complex fields and deposits reserves. Now, only 41%, proper, the gold ore fields and deposits are of its own free – milling, of which more than half are belonged to the technically resistant category with low gold content [2].

The resource base depletion of the gold mining enterprises and companies, anyway, is made to be raised the question on the involvement in the processing of the refractory gold – bearing ores with low gold content. Abroad, this challenge solution has already been begun on the massive scale, after the low – cost technologies appearance for the gold extracting from the poor ores. In particular, the mining production wastes with the metal content of 0,8 – 1,5 g./t. are become actively involved into the processing by the heap leaching method [3].

The solution of above – indicated challenge is, practically, presented the particular relevance and special urgency, especially for Kazakhstan. So, the overwhelming majority of the gold ore fields and deposits in Kazakhstan, are involved into the gold production, are presented themselves the refractory ones and, usually, refractory cyaniding gold – bearing ores of the copper porphyritic type with the low gold content. For example, the gold content does not exceed 0,1 – 0,2 g./t. in the major Kazakh fields and deposits of this type (e.g. «Aktogai, «Aidarly, «Kounrad, «Koksai). A number of the ore objects (e.g. «Samarskoe, «Kokstalzhal) are characterized by containing of 0,2 – 0,8 g./t. The increased gold contents have also been fixed in the ores of the copper vein type field and deposit «Shatyrkol» (e.g. 0,8 g./t.) [1].

It is required the special and individual approach, having based on the structured complex studies carrying out, for the new technologies to be created and to be developed, having provided the greatest gold extraction from these types of the ores [4 – 6].

The new technologies creation, having aimed at the processing of the refractory gold – bearing ores with the low gold content, with more evidence and confirmation of their holdings and reserves, is the significant reserve expansion in the gold production volumes in Kazakhstan.

The possibility and development of the technological conditions of the gold leaching from the complex copper-, gold – bearing ore, which are typical for a number of the gold – bearing fields and deposits in Kazakhstan, have already been studied by us in this paper.

The Research Methods.

The researches conducting have been involved several stages – definition phase, the chemical composition of the original ore and, directly, the experiments themselves conduction on the gold leaching from the gold – bearing ore in the field and deposit of the Southern Kazakhstan.

The ore phase composition definition has been conducted by the petrographic and mineralogical researches – by the study of the solid and powder samples of the original gold – bearing ore. The mineralogical researches of the solid samples have already been conducted, using the «MIN – 8» microscope. The mineralogical composition of the origin ore has been determined by the researches of the previously prepared powered samples under the «OLYMPUS» microscope in the transmitted light in the immersion environment, at the further increasing up to 400x.

The analysis chemical method and the «Axios PANalytical B.V» roentgen – fluorescent spectrometer (Holland) have been used for the determination of the elemental composition of the ore.

The rational composition of the original ore has been determined by the preliminary experiments, using the bottle leaching method. It has been determined, that the content of the easily cyanided gold in the original ore – 0,43 g./t. or 54,4% of the total gold content in the original ore. For all this, 36,7% is accounted for a share of the free easily cyanided gold, and the rest 17,7% – for a share of the free easily cyanided gold, having found in the joints.

The technological experiments on the gold extraction from the copper-, gold – bearing complex ore have been conducted by the sludge leaching method. The average content of the main elements in the original ore, having accepted for the experiments conduction, has been made up: gold 0,79 g./t., silver < 0,5 g./t., copper less, than 0,1% and sulphur total ~0,013%.

The selection of the experimental conditions has been carried out on the basis of the experimental design and planning. Following the «steep ascent» methodology, the procedure of the fractional replication of three – factor experiment variables has been realized: the solvent concentration (NaCN) – (х1), the pulp density (e.g.Т:Ж) – (х2), and the leaching duration – (х3).

The pulp density (e.g.Т:Ж) has been varied from 1:1 up to 1:2 in these carried out experiments. The solvent concentration has been ranged from 0,05% up to 0,5%. The experiments duration, ceteris paribus, has been made up – 8 h., 12 h., 24 h., and 48 h.

The barium oxide and calcium oxide costs, in all the carried out experiments, have been constant and have been amounted 1 g. and 0,2 g., respectively. The band-and-hook-hinge of the original ore, in all the carried experiments, has been constant – 200 g. The size of the original ore – has been (-1+0,0) mm. The water volume consumption, in all the carried out experiments, has been constant, and it has been made up 123 ml.

After each series of the experiments completion, in the sediment leaching – the gold content has been determined in кеке, whereupon the loss of the gold with кеком has been calculated and, further, the gold extraction in the solution.

The Experimental Results and Their Discussion.

The petrographic researches of the gold – bearing ore rock have been shown, that the original ore is, practically, presented by the gold – bearing beresite Late – Ordovician granodiorites with the thick vein with marked sulphide of iron and copper mineralization. The ore is consisted of the numerous large (e.g.1,0 – 1,5 mm.) quartz «points», having presented themselves the round or lenticular formations, often strongly cataclastic in the granoblastic aggregate and basic underlying tissue. The latter has been folded by the unit of the sub-paralleled orientated sericite scales with the small amount of chlorite and sub-paralleled interbedded iron hydroxides. The carbonate and ore dissemination are indicated in their small amounts. The prismatic crystals of the feldspar are observed, which are entirely substituted by the aggregate of the thin – scaly sericite with a small amount of quartz, as well as lamellar, seldom, at least, vaguely diamond – shaped grains of the mafic minerals, having entirely substituted by the chlorite and muscovite. The gold in the original ore is associated with the pyrite psevdo-amorphous aggregates. The native gold isolations are, practically, confined to the goethite aggregates cracks, having formed the elongated-irregular shapes and veins, the size of the first microns up to 0,15 mm. in them.

In order to be clarified the mineral composition of the ore, previously prepared powered sample were subjected to the mineralogical studies under the «OLYMPUS» microscope in the transmitted light in the immersion environment, at the further increasing up to 400x.

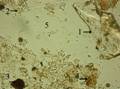

In some photo-pictures of the powered samples of the original ore, having photographed under the microscope (Fig.1), clearly expressed phases of quartz, feldspars, and iron hydroxides (e.g. goethite) can be seen. The predominant amounts of the hematite, which are formed in result of the magnetite crystals replacement, have been found.

Fig.1. Photos of the original ore samples, 400x.

1 – quartz; 2 – feldspar; 3 – hematite; 4 – iron hydroxides (e.g. goethite);

5 – immersion medium.

Along with the defined phases, the other phases – sericites, chlorites, and carbonates have already been found in the original ore.

In result of the carried out studies, the mineral composition of the original ore, which is presented in the Table No.1, has been established.

The Table No.1.

The Mineral Composition of the Original Gold – Bearing Ore.

|

The Minerals Name |

Content, %

|

The Minerals Name |

Content, % |

|

Quartz |

32,9 |

Galenite (galena) |

* |

|

Sericite, rarely muscovite |

23,2 |

Cerussite |

* |

|

Feldspars |

16,4 |

Chalcosine (chalcocite) |

* |

|

Chlorites, rarely biotite |

13,7 |

Chrysocolla |

* |

|

Carbonates |

8,2 |

Covellite |

* |

|

Iron Hydroxides |

5,3 |

Grothite |

* |

|

Hematite |

1,7 |

Zircon |

* |

|

Magnetite |

0,6 |

Pyrite |

** |

|

Apatite |

0,4 |

Chalcopyrite |

** |

|

Rutile |

0,3 |

Malachite |

** |

* single grains; ** rare grains.

The results of the studies by the elemental composition of the original ore determination have been presented in the Tables No. No. 2,3.

The Table No.2.

The Results of the Spectral Elemental Analysis of the Original Gold – Bearing Ore.

|

Elements |

Symbols |

Content, % |

Elements |

Symbols |

Content, % |

|

Copper |

Cu |

0,080 |

Yttrium |

Y |

2*10-3 |

|

Vanadium |

V |

0,010 |

Lead |

Pb |

1,5*10-3 |

|

Zirconium |

Zr |

0,012 |

Gallium |

Ga |

1,5*10-3 |

|

Strontium |

Sr |

0,025 |

LithiumLi |

1,5*10-3 |

|

|

Phosphorus |

P |

0,05 |

Scandium |

Sc |

1,2*10-3 |

|

Barium |

Ba |

0,10 |

Cobalt |

Co |

1,2*10-3 |

|

Manganese |

Mn |

0,10 |

Bithmus |

Bi |

5*10-4 |

|

Titanium |

Ti |

0,3 |

Molybdenum |

Mo |

5*10-4 |

|

Niobium |

Nb |

0,6 |

Ytterbium |

Yb |

2,5*10-4 |

|

Zinc |

Zn |

5*10-3 |

Tin |

Sn |

2*10-4 |

|

Chrome |

Cr |

5*10-3 |

Germanium |

Ge |

0,8*10-4 |

|

Nickel |

Ni |

4*10-3 |

Silver |

Ag |

2*10-5 |

The Table No. 3.

The Results of the Chemical Analysis of the Original Ore.

|

Elements |

Symbols |

Con- tent, % |

Elements |

Symbols |

Con- tent, % |

|

Silicon dioxide |

SiO2 |

59,67 |

Titanium dioxide |

TiO2 |

0,45 |

|

Aluminum trioxide |

Al2O3 |

15,49 |

Sulfur pyrite |

Spyrite |

<0,25 |

|

Iron trioxide |

Fe2O3 |

6,24 |

Sulfur total |

Stotal |

0,0125 |

|

Calcium oxide |

CaO |

4,81 |

Phosphorus pentoxide |

P2O5 |

0,18 |

|

Iron oxide |

FeO |

3,61 |

Manganese oxide |

MnO |

0,16 |

|

Potassium oxide |

К2О |

3,61 |

Copper |

Cu |

0,092 |

|

Sodium oxide |

Na2O |

1,79 |

Lead |

Pb |

<0,02 |

|

Magnesium oxide |

MgO |

1,78 |

Zinc |

Zn |

<0,01 |

|

Gold, g./t. |

Au |

0,79 |

The others |

|

5,51 |

|

Silver, g./t. |

Ag |

<0,5 |

|

|

|

The Conditions of Experiments Conducting on the Gold-Bearing Ore Leaching by Sludge Method, and Their Results Are Given in the Table No. 4.

The Table No.4.

The Results of Sludge Leaching of the Origin Gold – Bearing Ore.

|

t., ho- ur |

Concen-tration NaCN, % |

The Pulp Density, Т:Ж |

||||||||

|

1:1 |

1:1,5 |

1:2 |

||||||||

|

Au in кеке |

Extra-ction Au in soluti-on, % |

Au in кеке |

Extra-ction Au in soluti-on, % |

Au in кеке |

Extra-ction Au in soluti- on, % |

|||||

|

Сon - tent, g./t. |

Losses, % |

Con - tent, g./t. |

Losses, % |

Con - tent, g./t. |

Losses, % |

|||||

|

8 |

0,05 |

0,29 |

36,71 |

63,29 |

0,26 |

32,91 |

67,09 |

0,24 |

30,38 |

69,62 |

|

0,10 |

0,26 |

32,91 |

67,09 |

0,24 |

30,38 |

69,62 |

0,22 |

27,85 |

72,15 |

|

|

0,25 |

0,22 |

27,85 |

72,15 |

0,20 |

25,32 |

74,68 |

0,21 |

26,58 |

74,42 |

|

|

0,50 |

0,20 |

25,32 |

74,68 |

0,19 |

24,05 |

75,95 |

0,20 |

25,32 |

74,68 |

|

|

12 |

0,05 |

0,26 |

32,91 |

67,09 |

0,26 |

32,91 |

67,09 |

0,24 |

30,38 |

69,62 |

|

0,10 |

0,24 |

30,38 |

69,62 |

0,24 |

30,38 |

69,62 |

0,23 |

29,11 |

70,89 |

|

|

0,25 |

0,20 |

25,32 |

74,68 |

0,20 |

25,32 |

74,68 |

0,22 |

27,85 |

72,15 |

|

|

0,50 |

0,20 |

25,22 |

74,68 |

0,20 |

25,32 |

74,68 |

0,21 |

26,58 |

76,42 |

|

|

24 |

0,05 |

0,24 |

30,38 |

69,62 |

0,25 |

31,65 |

68,35 |

0,24 |

30,38 |

69,62 |

|

0,10 |

0,22 |

27,85 |

72,15 |

0,23 |

29,11 |

70,89 |

0,22 |

27,85 |

72,15 |

|

|

0,25 |

0,19 |

24,05 |

75,95 |

0,22 |

27,85 |

72,15 |

0,22 |

27,85 |

72,15 |

|

|

0,50 |

0,18 |

22,78 |

77,22 |

0,20 |

25,32 |

74,68 |

0,20 |

25,32 |

74,68 |

|

|

48 |

0,05 |

0,20 |

25,32 |

74,68 |

0,20 |

25,32 |

74,68 |

0,20 |

25,32 |

74,68 |

|

0,10 |

0,20 |

25,32 |

74,68 |

0,18 |

22,78 |

77,22 |

0,19 |

24,05 |

75,95 |

|

|

0,25 |

0,15 |

18,99 |

81,01 |

0,16 |

20,25 |

79,75 |

0,16 |

20,25 |

79,75 |

|

|

0,50 |

0,15 |

18,99 |

81,01 |

0,15 |

18,99 |

81,01 |

0,15 |

18,99 |

81,01 |

|

The final results of carried out studies are shown the principal possibility of the gold extraction from the gold – bearing ore with low gold content by the leaching method.

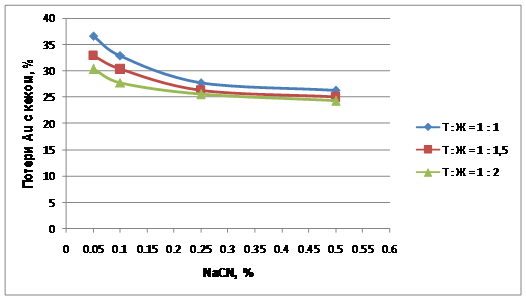

In Fig.1, A) it has been shown, that the gold extraction increasing in the solution is depended on the gold losses minimization with the кеком: at the leaching duration 8 hours, with the concentration increasing of sodium cyanide, the gold with кеком losses are being reduced. More scattered and diffused nature of the curves in the range of the cyanide concentration change from 0,05% up to 0,25%, is indicated on the degree of the pulp density influence on the gold losses with the кеком. The density of pulp further increasing from Т:Ж=1:1 up to Т:Ж=1:2 (e.g. at NaCN=0,05%) practically reduces the gold losses with the кеком for 7 – 9% abs. At the cyanide concentration further increase from 0,25% up to 0,5%, the pulp density on the gold with кеком losses is rendered only the weak effect. This is evidenced by the curves character in the Fig. 1, A), wherein in the indicated region of the cyanide concentration change, the curves are highly compressed to each other and have only the small spread.

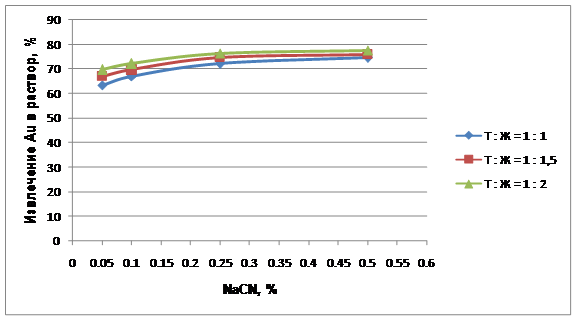

The analysis of the finite function dependence graph – the gold extraction in the solution, of the selected variable parameters, is in full agreement with the established, in the Fig. 1, A), regularities: the gold extraction in the solution is being increased with the increasing concentration of the solvent – sodium cyanide, the further increase of which is, practically, led to lower losses of the gold with кеком. For all this, the pulp density change towards further increase also is made only the minor contribution to the increase in the gold extraction in the solution (Fig.1, B).

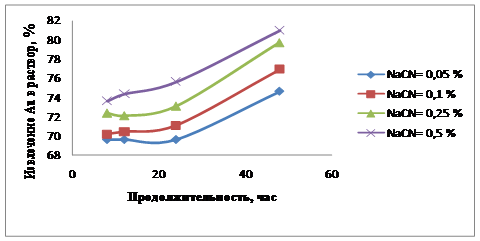

In the Fig. 2, it has been shown the leaching duration effect on the gold extraction in the solution at the constant pulp density Т:Ж=1:2, and the sodium cyanide various concentrations. It, moreover, can be seen, that in the contrast to the solvent concentration and pulp density, the leaching time increase has the great impact on the gold extraction completeness from the gold – bearing ore. For example, at the constant values of the sodium cyanide and the pulp density, the gold extraction increase from the original ore in the solution is further increased with the leaching time increase, and it is reached the maximum at the sodium cyanide elevated concentration (e.g. 0,5%) and the leaching time, which is equal to 48 hours.

Thus, the obtained final results by the gold – bearing ore leaching are, practically, shown, that gold extraction completeness from the ore is determined, on the one hand, by the gold with кеком losses reduction, on the other hand, – the necessary conditions creation for its further extraction from the refractory part. It should be optimized, primarily, the solvent concentration (e.g. sodium cyanide), the initial size of the original ore, and the leaching time, for the gold extraction increase in the solution at the leaching. For all this, regardless of the fact, that pulp density for the gold extraction is affected insignificantly, to neglect it, in view of its significant impact on the gold with кеком losses, should not do it.

Au losses with the кеком, %. A)

Au extraction in the solution, % B)

Fig.1. The solvent concentration impact (e.g. NaCN) and the pulp density

for the gold with кеком losses A) and the gold extraction in the solution

B) at the leaching duration 8 hour.

a) Au extraction in the solution, %; b) Duration, hour.

Fig.2. The gold extraction dependence in the solution

from the leaching duration (e.g.Т:Ж=1:2).

The suggested assumptions and established regularities, having obtained, experimentally, are fully confirmed by the results of the mathematical processing of the obtained data.

The assessment of the correlation degree of the desired function – the gold with кеком losses (у1), with each separately taken variable parameter – with the sodium cyanide concentration (х1); with the pulp density (х2), the leaching duration (х3) has been allowed to be received the following pair correlation equations:

у1 = 0,2364 – 0,1128 х1 r = 0,66; (1)

у1 = 0,2422 – 0,0028 х2 r = 0,24; (2)

у1 = 0,2122 – 0,0014 х3 r = 0,61. (3)

The low value of the simple correlation coefficient (r = 0,24) of the equation (2) is indicated on the weak influence of the pulp density (х2) on the gold with кеком losses (у1).

Nevertheless, the multiple correlation equation (4), having described the gold with кеком losses, depending on all three variables, is rather very high value of the multiple correlation coefficient (r = 0,90), which is indicated on the effect of the pulp density at the desired value:

у1 = 0,2687 – 0,1128 х1 – 0,0028 х2 – 0,0014 х3 (4)

Thus, the final equation of the multiple correlation, having predicted the gold extraction in the solution (у) at the leaching, depending on the sodium cyanide concentration (х1), the pulp density (х2), the leaching duration (х3), and the gold with кеком losses (у1) has the following form:

у = 0,0035 – 0,0188 х1 – 0,0092 х2 – 0,0065*10-2 х3 + 126,55 у1 (5)

r = 0,98.

The Conclusions:

1. The final results of the mineralogical studies, rational and chemical composition of the complex gold – bearing ore have been given. The principle possibility of the gold extraction by the sludge leaching method from the ore grain size (-1,0+0,0) mm., having contained 0,79 g./t. gold, less 0,5 g./t. silver, and less 0,1% has been shown.

2. As a result of the rational composition of the original ore studies it has been found, that even in the grain size (-1,0+0,0) mm., the content of easily cyanided gold in the original ore is made up 0,43 g./t. , or 54,4% of the total gold content in the original ore. Moreover, 36,7% of them, is accounted for a share of the free gold, and the remaining – 17,7% – for a share of the gold, having located in the splices.

3. It has been shown, that for maximum gold extraction in the solution from the original ore, it is necessary to be conducted a finer division of the original material and the provision of the high cyanic solution concentration (e.g. 0,5%). This will allow to be increased the gold extraction from the refractory portion of the original ore and, significantly, to be reduced the leaching time.

2. Bekzatov A.,” The Gold of Kazakhstan: a Short Review”. // «Uralgold», 2014;

3. Makarov V.A., ”The Gold of Technogenic Mineral Objects – Resources and Challenges of Geological and Technological Assessment”. // «Gold and Technologies», 2011, № 3 (13);

4. Seydaly A.S., Goroshko E.V. , ”The Prospects for Development of Gold – Mining Industry in Kazakhstan”. – «Almaty,: KazGOSINTI», 1999;

5. Lodeyshchikov V.V., ”The Gold and Silver Extraction Technology from Refractory Ores”. // JSC «Irgiredmet», Irkutsk, 1999, p. 786;

6. Meretukov E.N., Orlov A.M., ”The Precious Metals Metallurgy. Foreign Experience”. – М.: «Metallurgy», 1991.

Dosmukhamedov N.K., Komkov A.A., Dauletbakov T.S., Mambetaliyeva A.R., Zholdasbay E.E THE COPPER – BEARING COMPLEX POOR ORES

PROCESSING TECHNOLOGY SELECTION AND JUSTIFICATION

. International Journal Of Applied And Fundamental Research. – 2014. – № 2 –

URL: www.science-sd.com/457-24706 (22.02.2026).

PDF

PDF