About Us

Executive Editor:Publishing house "Academy of Natural History"

Editorial Board:

Asgarov S. (Azerbaijan), Alakbarov M. (Azerbaijan), Aliev Z. (Azerbaijan), Babayev N. (Uzbekistan), Chiladze G. (Georgia), Datskovsky I. (Israel), Garbuz I. (Moldova), Gleizer S. (Germany), Ershina A. (Kazakhstan), Kobzev D. (Switzerland), Kohl O. (Germany), Ktshanyan M. (Armenia), Lande D. (Ukraine), Ledvanov M. (Russia), Makats V. (Ukraine), Miletic L. (Serbia), Moskovkin V. (Ukraine), Murzagaliyeva A. (Kazakhstan), Novikov A. (Ukraine), Rahimov R. (Uzbekistan), Romanchuk A. (Ukraine), Shamshiev B. (Kyrgyzstan), Usheva M. (Bulgaria), Vasileva M. (Bulgar).

Engineering

Strengthening of natural components in the national education makes a deeper study of modern information technologies, aimed at the improvement of the engineering design and the development of virtual design. Such advanced technology can certainly be attributed to the technology of digital prototypes implemented in CAD/CAE-package Autodesk Inventor Professional. This is a powerful tool of development of digital models (prototypes) engineering products, taking into account not only the slightest nuances geometric form, but physical and mechanical properties of constructional material and allows, therefore, in semi-automatic mode to perform the whole complex of works on development of three dimensional virtual images from elementary parts to complex technical systems and full-scale architectural complexes, including the production of the necessary con-structural documentation (drawings, specifications).

One of the characteristic features of this software is its ability to interactively monitor the correct implementation of the parts in the site, the tracking presence mates and taking into account their mutual mobility (degrees of freedom kinematic pairs). Virtual test work products developed in Inventor, reduces the probability of errors and increase the technological effectiveness of production. Possible test of crossings static parts with backlighting (figure 1) intersecting parts (collisions)and check of potential intersection of the moving parts of the mechanism using variations of dependency or drag-and-drop components.

Figure 1

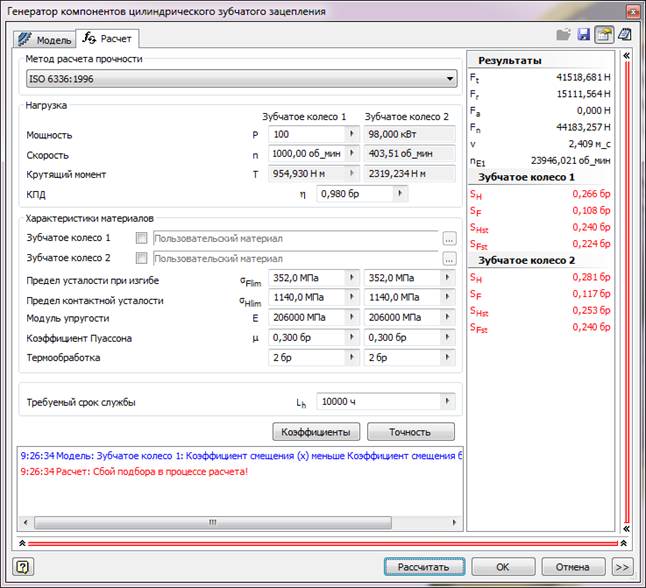

Automatic monitoring of observance of the important design parameters allows to reduce the likelihood of errors. This feature allows you to control the length, distance, angle, diameter, perimeter loop, area, volume and weight. When the values of monitored parameters beyond the specified range, you receive a warning signal. Offset error is a diagnostic tool with which you can identify potential problems in the design and find ways to correct them (figure 2).

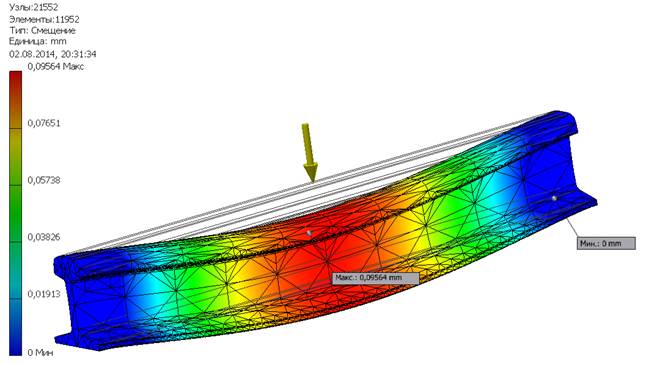

Function analysis by finite element method (figure 3), intended for calculation of stresses and strains, helps to improve quality of products and prevent operational faults. Dynamic analysis allows to calculate the strength and speed for each part in real conditions with variable load, friction and dynamic behavior of components such as springs and dampers.

Figure 2

The issues noted above makes indispensable Autodesk Inventor during the development of such basic engineering disciplines: "Theory of mechanisms and machines", "Resistance of materials" and "Machinery" [1,2].

Besides, the technology of digital prototypes, implemented in CAD Autodesk Inventor allows the engineer with maximum efficiency to realize their creative potential is not being distracted by routine operations, and learned objectively and adequately analyze the object of study for adoption optimal solutions for the choice of reasonable values of the parameters of a technical system.

Figure 3

2. Бышов Н.В., Кравченко А.М., Борычев С.Н. и др. Основы инженерного проектирования: монография. – Рязань, РГАТУ, 2011.

Kravchenko A.M. THE TECHNOLOGY OF DIGITAL PROTOTYPES IN ENGINEERING EDUCATION. International Journal Of Applied And Fundamental Research. – 2014. – № 3 –

URL: www.science-sd.com/458-24597 (03.03.2026).

PDF

PDF