About Us

Executive Editor:Publishing house "Academy of Natural History"

Editorial Board:

Asgarov S. (Azerbaijan), Alakbarov M. (Azerbaijan), Aliev Z. (Azerbaijan), Babayev N. (Uzbekistan), Chiladze G. (Georgia), Datskovsky I. (Israel), Garbuz I. (Moldova), Gleizer S. (Germany), Ershina A. (Kazakhstan), Kobzev D. (Switzerland), Kohl O. (Germany), Ktshanyan M. (Armenia), Lande D. (Ukraine), Ledvanov M. (Russia), Makats V. (Ukraine), Miletic L. (Serbia), Moskovkin V. (Ukraine), Murzagaliyeva A. (Kazakhstan), Novikov A. (Ukraine), Rahimov R. (Uzbekistan), Romanchuk A. (Ukraine), Shamshiev B. (Kyrgyzstan), Usheva M. (Bulgaria), Vasileva M. (Bulgar).

Engineering

Production of high quality products is provided by modern conditions of internal market development and foreign trade impact of current situation on it. Increasing of the competitiveness of products for Russian footwear industry is the main question. One way of solving the problem is to increase the quality of the footwear due to applying of new materials or materials with modified and structured characteristics.

The most typical and common vices of footwear made of genuine leather are defects in top layer defects of leather: cracks, crumbling film, tearing, abrasions, and others [1].

Coating and top layer cracks of leather are caused at the crease line by the damage due to fatigue because of repeated mechanical action (bending, stretching) and insufficient adhesion of the coating film. The number of surface defects and the nature of their location among the footwear upper is largely determined by the type and properties of the leather. Chrome footwear surface defects do not cause the termination of its operation in most cases, but significantly detract the appearance. There is no effective means to remove these defects. In addition, a number of surface defects during further operation can turn into a cross-cutting.

The most common cross-cutting defects are stripping and tearing resulting from external mechanical influences. Along with this, cross-cutting cracks appear in footwear with uppers of chrome tanning leather, including the cattle leather in the area of the bend, emerging from the surface cracks of the top layer of the dermis, as well as through attrition of toe, vamp, backdrop formed from surface abrasions by influence of repeated foot punching during the prolonged exploitation [2].

Loss of shape and trampling are also belong to chrome uppers defects of footwear significantly worsen its appearance. The extent of these defects across the area and the rate of occurrence determined by the properties of leather used for the uppers, right mix of materials and pads, the degree of properties changes at molding of uppers, as well as the conditions of its operation. Besides, there are significant numbers of defects arising by the influence of external influences of exploitation due to the deterioration of physical and mechanical properties of materials. Numerous scratches are the most frequently encountered.

Terms of genuine leather uppers exploitation, the nature and location of defects on it depend on the type of footwear. The greatest number of cross-cutting defects is observed among the army footwear, which is subjected to more intense wear than the other [3].

Materials properties are the most significant for the assessing of the quality of footwear made of chrome tanning genuine leather, as they predetermine the technology of manufacturing of products and the rules for operation.

Therefore the effect of radio frequency low pressure plasma on the mechanical characteristics of the workpiece of chrome-tanned uppers of cattle was investigated. The effect of exposure to the plasma was determined by comparing the characteristics of the materials treated in the radio frequency capacitive discharge with the characteristics of control samples.

The parameters of radio frequency capacitive discharge were the following: discharge power Wp = 0,15-2,01 kW, plasma gas flow (argon) G=0,04-0,12 g/s, the operating pressure in chamber P=13,3 -80 Pa, time of treatment t = 1 – 15 min.

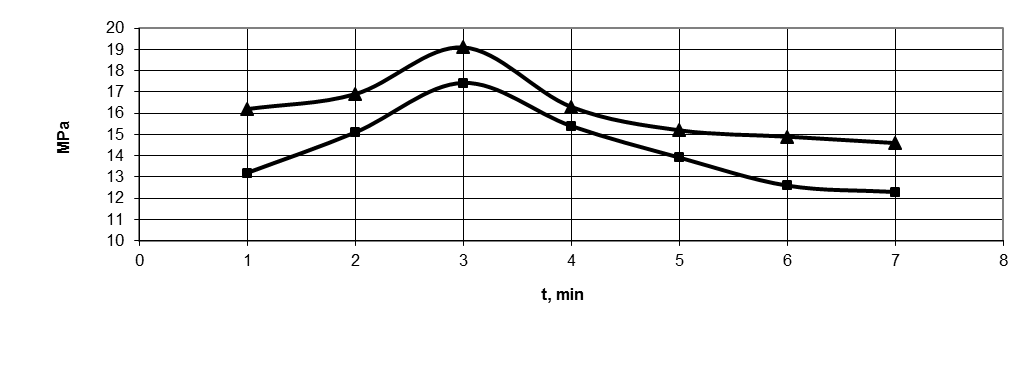

Figure 1 shows the dependence of the tension during the appearance of the top layer cracks and the tensile strength of the leather on the duration of the plasma treatment.

Figure 1 shows that the indicators of stress during the appearance of the top layer cracks and the tensile strength of the upper leather are the most at the following parameters of the plasma treatment Wp = 1,6 kW, P = 13,3 Pa, G = 0,04 g/s, t = 3min. The following increasing of the plasma processing time these parameters fall down [4].

Fig. 1. Dependence of the strength of the uppers made of cattle leather on the duration of plasma treatment

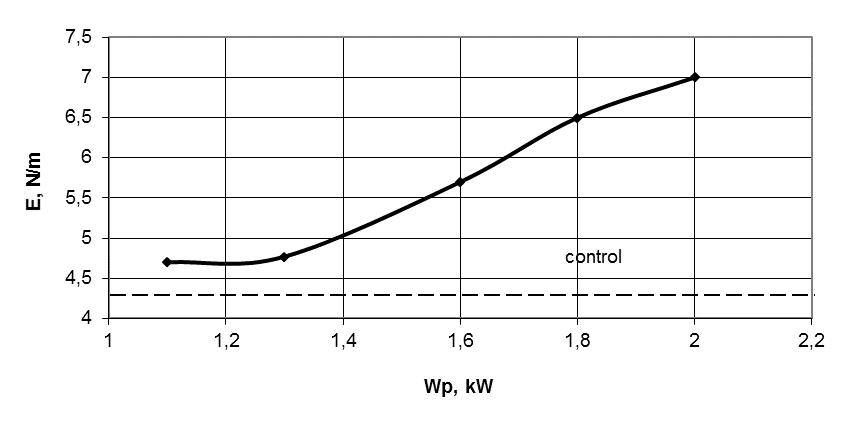

Modulus of elasticity is one of the indicators that characterize the material's resistance to stretching. The calculation of the elastic modulus and hardness is carried out during deformation of the material (fig. 2).

Fig. 2. Dependence of elasticity modulus of the uppers made of cattle leather on the discharge power (P=13,3 Pa, GAr=0,04 g/s, t = 3 min)

Figure 2 shows that plasma treatment enhances the elastic modulus at the following parameters Wp=1,6 kW, P=13,3 Pa, GAr=0,04 g/s, t = 3 min. Elasticity modulus of uppers after treatment increased by 30% comparing with the control sample.

The results of studies of the effect of plasma treatment on the mechanical properties are shown in Table 1.

Table 1. Effect of RF - plasma on the mechanical properties of the uppers made of chrome tanning cattle leather (P=13,3 Pa, GAr=0,04 g/s, t = 3 min)

|

Sample |

Control |

Wp=1,6 kW |

Wp=1,8 kW |

|

Leather resistance to flexure, points Resistance to abrasion, points Elongation stress 10 MPa, % |

3 40

35 |

4 61

34 |

4 60

33 |

Table 1 shows that leather resistance to flexing was increased after plasma treatment relative to the control by 33%, abrasion resistance by 50%, the elongation stress at 10 MPa after plasma treatment decreases relative to the control by 3-6 %.

The impact of nonequilibrium low-temperature plasma on the materials of textile industry could lead to changes in the structure of the material.

For leather materials mechanical properties are determined by the forces of structural elements cohesion and the coupling strength between the structural elements of the material and are characterized by the influence of external forces on the material [5]. Radio frequency discharge increases the mechanical properties due to the change in the spatial conformation of macromolecules in the material as a result of its straightening and increasing the distance between the fiber bundles. The increased modulus of elasticity of chrome-tanned cattle leather is associated with an increase of the average density of fibers and hardening of the molecular bonds.

The results of element analysis of samples of chrome-tanned cattle leather are presented in table 2. It has been established that plasma treatment does not alter the chemical composition of leather.

Таble 2 – Influence of plasma treatment on the element analysis of cattle leather (P=13,3 Pa, GAr=0,04 g/s, t = 3 min)

|

Sample |

Elements, % |

|||||||

|

C |

N |

O |

P |

Al |

S |

Cl |

Cr |

|

|

Control |

62,34 |

10,08 |

20,24 |

0.44 |

0.80 |

2.22 |

0.51 |

3.37 |

|

Experimental |

59.56 |

11.91 |

22.71 |

- |

0.30 |

1.94 |

0.19 |

3.38 |

Thus, the research results show that the RF plasma treatment allows to increase the mechanical properties of footwear materials which save product consumer characteristics with lifetime increasing.

2. Analysis of production and operational impacts of the environment on natural polymers. Garipova G.I., Makhotkina L.Yu. Bulletin of Kazan Technological University. 2013. V.16. № 19. p.186 -187.

3. Regulation of the forming ability of complex materials for footwear industry with the use of low-temperature nonequilibrium plasma / Makhotkina L.Yu. // Thesis for the degree of Doctor of Technical Sciences / Kazan, 2006.

4. The method of treating leather. Abdullin I.Sh., Makhotkina L.Yu., Fakhrutdinova G.R. A patent for an invention RUS 2298040. 22.09.2005.

5. Processing of footwear materials by RF plasma of low pressure. Makhotkina L.Yu. Leather and footwear industry. 2006. №5. P.36-37.

Makhotkina L.Y., Khristoliubova V.I. VARIATION OF FOOTWEAR WEAR RESISTANCE DEPENDING ON METHODS OF TREATMENT. International Journal Of Applied And Fundamental Research. – 2015. – № 1 –

URL: www.science-sd.com/460-24749 (04.03.2026).

PDF

PDF