About Us

Executive Editor:Publishing house "Academy of Natural History"

Editorial Board:

Asgarov S. (Azerbaijan), Alakbarov M. (Azerbaijan), Aliev Z. (Azerbaijan), Babayev N. (Uzbekistan), Chiladze G. (Georgia), Datskovsky I. (Israel), Garbuz I. (Moldova), Gleizer S. (Germany), Ershina A. (Kazakhstan), Kobzev D. (Switzerland), Kohl O. (Germany), Ktshanyan M. (Armenia), Lande D. (Ukraine), Ledvanov M. (Russia), Makats V. (Ukraine), Miletic L. (Serbia), Moskovkin V. (Ukraine), Murzagaliyeva A. (Kazakhstan), Novikov A. (Ukraine), Rahimov R. (Uzbekistan), Romanchuk A. (Ukraine), Shamshiev B. (Kyrgyzstan), Usheva M. (Bulgaria), Vasileva M. (Bulgar).

Engineering

The interest in carbon nanotubes (CNTs) and the breadth of research activities across the world on their application potential have been extraordinary in the last decade. CNTs were first discovered by Sumio Iijima of the NEC Corporation in 1991 [1] in the soot of an arc discharge apparatus. These are elongated fullerenes with diameters as small as 0.7 nm and lengths of up to several microns.

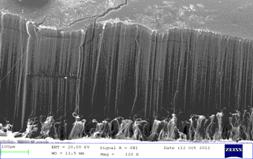

Fig.1: High Magnification of the forest type CNTs that were produced by CVD system. a, MWNTs and b, Separated morphologies of MWNTs

2. Electrical Property

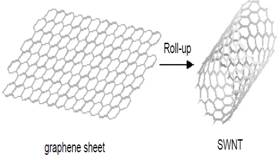

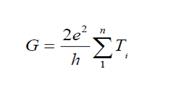

When a grapheme sheet rolls up into a SWNT, confinement of electrons around the circumference is observed [1]. The unique electrical properties of SWNT arise from such confinement of the electrons, which can move in a several micrometer scale only along two directions at room temperature. Here the transport is ballistic hence the terminal conductance (G) of a one dimensional system is given by Landauer equation [2].

where 2e2/h is the quantum of conductance and Ti is the transmission coefficient of each contributing subband (conduction channel) produced by the confinement of electrons along the circumference of the CNT. The electronic transport properties of CNT can change depending on: the degree of graphitization, chirality, diameter, the microstructure of the tube, extent of functionalization and doping [2]. The remarkable peculiarity of CNT is the possibility of band gap engineering by control of their microstructure.

2.1 Tensile testing

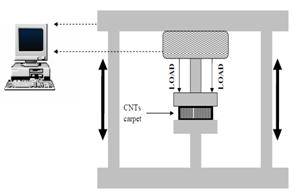

The test was performed on a universal testing machine (MTS Sintech).Recent test shows an improvement of this value over 2 GPa. The idea to use micro-tweezers to traction tests is on trial [3].

Fig.2: experimental set-up for mechanical compression of CNTs carpet.

The controversy about the hydrogen storage capability is mostly caused by insufficient characterization of the used samples. At the beginning the studies suggested a storage capacity of 60 % wt, but subsequently more realistic estimates reported a 8-10 % wt value. Anyway, it turned out that the hydrogen storage capacity of nanotubes is less than 1%, which is not enough to define CNTs as a material useful for realistic devices for hydrogen storage.

2.2 Experimental system

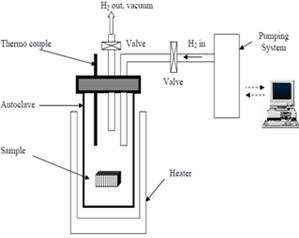

The experimental system consists of an autoclave where hydrogen gas (high purity grade, 99,99%) is pumped inside. A vacuum system is connected to the sample chamber. The number of mole, it was pumping into the autoclave before and after loading MWCNTs are monitored by a specific system controlled by a PC. Also temperature is monitored by a thermocouple. The system used for low temperature experiments is not recommended.

Fig.3: Experimental Setup of H2 Storage in CNTs.

3. RESULTS AND DISCUSSION

In absence of the electron scattering, the resistance of metallic SWNT was calculated to be 6.5 kΩ by using Landauer equation. The resistance is due to the quantum mechanical coupling of the two conducting subbands in the nanotubes with the connecting leads. This is unavoidable, and every interconnect made with perfect CNT would have at least similar resistance. It has been shown that the major contribution in conductance of carbon nanostructure comes from the π electrons and only a very small part from the σ electrons. The contribution of σ and the coupling of σ - π electrons were found to be significant only in the case of bent CNT.

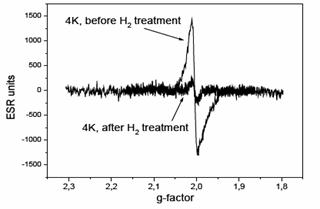

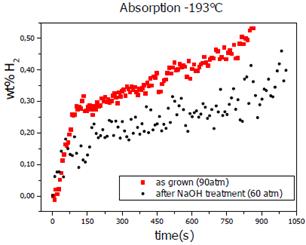

Best results of hydrogen adsorption have been obtained at 190°C using the first set of MWCNTs ( high area surface, 20-80 m2g-l) with a time exposure of 1 hour. In MWCNTs at low temperature, the quality is not so high (low area surface), and also the ones after NaOH treatment have not evidenced an increased area surface as it was expected. Also to put in evidence the different time exposure which could have been an key role in the amount of hydrogen storage. In order to evaluate the interaction between hydrogen and CNTs surface, an electron spin resonance spectroscopy (ESR) has been done on SWCNTs before and after hydrogen treatment. ESR spectroscopy is a technique use to study chemical species that have one or more unpaired electrons, such as organic and inorganic free radicals or inorganic complexes possessing a transition metal ion.

Fig.4: ESR spectrum of CNTs before and after the H2 exposure.

Fig.5: Hydrogen storage at low temperature in carbon nanotubes before and after NaOH treatment.

4. CONCLUSION

CNTs produced by CVD in our laboratory have a mm-thick and large carpet deposition area. This technique is simple, cost effective and easy to scale up, a way to rapidly produce great quantities of CNTs using low cost reagents. Since the capacitance is equal to C = A/d, materials with high surface area A give an obvious advantage, also yielding high power densities (directly proportional to C ). In addition, nanotubes provide better performance also than activated carbons by which it has been fabricated the first super capacitors, possessing the largest surface area of any other carbon and lower resistance, that leads to higher power density. At the moment CNTs/nanofibers are used to improve the conductivity and surface area of electrodes in Li-ion batteries, and fuel cells. By controlling the type and the size of the nanotube clusters, you can expect to regulate the tuning of the material for hydrogen sorption at the desired temperatures and pressures.

5. ACKNOWLEDGMENTS

This research was partially support by a grant from the Carbon Nanotubes Research Initiative Program of Nano sub-departments of DSSTRC and was also supported by the Faculty of Advance Technology Research was funded by the Ministry of Defense of Myanmar.

[2] W. Zhu, C. Bower, O. Zhou, G. Kochanski and S. Jin, “Large current density from carbon nanotube field emitters”, Appl. Phys. Lett., Vol. 75(6), pp. 873-875, (1999).

[3] N. Wang, Z.K. Tang, G.D. Li and J.S. Li, “Materials science - Single-walled 4 angstrom carbon nanotube arrays”, Nature, Vol. 408(6808), pp. 50-51, (2000).

Kyaw Myo Aung, Myo Thant, Kyaw Myat Thu, Kyaw Myo Zaw, Kyaw Zaw Ye Investigation of The Properties of CNT that was produced by Chemical Vapor Deposition System. International Journal Of Applied And Fundamental Research. – 2015. – № 2 –

URL: www.science-sd.com/461-24804 (28.02.2026).

PDF

PDF