About Us

Executive Editor:Publishing house "Academy of Natural History"

Editorial Board:

Asgarov S. (Azerbaijan), Alakbarov M. (Azerbaijan), Aliev Z. (Azerbaijan), Babayev N. (Uzbekistan), Chiladze G. (Georgia), Datskovsky I. (Israel), Garbuz I. (Moldova), Gleizer S. (Germany), Ershina A. (Kazakhstan), Kobzev D. (Switzerland), Kohl O. (Germany), Ktshanyan M. (Armenia), Lande D. (Ukraine), Ledvanov M. (Russia), Makats V. (Ukraine), Miletic L. (Serbia), Moskovkin V. (Ukraine), Murzagaliyeva A. (Kazakhstan), Novikov A. (Ukraine), Rahimov R. (Uzbekistan), Romanchuk A. (Ukraine), Shamshiev B. (Kyrgyzstan), Usheva M. (Bulgaria), Vasileva M. (Bulgar).

Engineering

Agricultural machines are multifunctional and complicate technological machinery, and a person, who contributed a lot to these researches, was one of the founders of theory of mechanisms and machinery Goryachkin P.V. This article is devoted to the history of appearance and development of rotary hiller – machines with active rotational working elements. They are produced for milling medium and heavy soils, and this process directs to weed out, to mix proportionally fertilizer with soil, to make small cloddy structure of distended layer. In this article, we solve the problem of detection of evolution stages and the main tendencies of their perfecting on the base of evolution law of technical systems.

1. Stages of rotary hiller’s development

The rotary hiller, as any other new technological contracture, appeared in definite stage of development of science and technology, when two main conditions were realized [1]: necessity in a system and solving the problem of its realization. As the rule, these conditions realize not at the same time, and usually the one stimulates the other. In this case, there is necessity to cultivate medium and heavy soils with required quality and high productivity from the one hand, and there is technology of metalworking and tilling by rotary hillers from the other hand. Their development, as the other systems, was going according to the S-law [1, 2, 3] (initiation, development, regress).

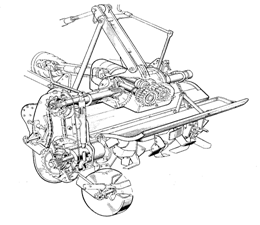

Initiation. New system is elementary enough at the stage of the initiation, and has many disadvantages, that is why this system needs the modernization. Effectiveness of the system is lowest at this stage, often negative, there is no benefit, and expenses are high. One of these causes is the contradiction between new content and old form, where they realize. At the first stage, the main motive force of technical system’s development is personal interest of its creators. The main development of the system is to decrease hazards (increase the safety, failsafe, convenience of using). When the society understands the usefulness, and hazards decrease, it is the beginning of a new stage of its development. Therefore, the rotary hillers have more than the hundred years’ history of utilization. At the beginning of the XX century, different countries produced a great number of variant constructions. Nevertheless, all of these machines worked on steam-power, their constructions were huge and complicated, unhandy for service and unreliable at operation. In 1850 Frenchmen Guibal and Thénard, Englishman Haskins were projected machines with rotary working elements. Later Englishmen Derby in 1865 and Cooper in 1875 were trying to create a machine with forked working elements and with forcing actuator from the steam engine.

Development [2].The main content of this stage is fast, reminding a chain reaction, development. The specific feature of this stage is active expansion of a new system, which was forcing out other obsolete models from the production niches, and it helped to create a quantity of new modifications and variants, adapted to different conditions and aims. The main driving force at this stage was social need, which was like the demand to the system from the side of the environment. On the second stage, the technological system became profitable and the effect was permanently increasing.

Continuing the theme of rotary hiller, a prototype of their modern constructions was the rotary hiller with spring working elements on the base of a tractor with the internal-combustion engine of the 5 horsepower, which was made by Meyenburg in 1910 in Switzerland. For the first time Siemens-Schuckert company arranged their repetition work. After that, began to create and modernize constructions of rotary hillers all over the world: Howard, Australia; (Косзеджи) Hungary; and others. Imperfection of rotary hiller’s constructions posed a problem for researcher to make theoretical and experimental investigations. Switzerland, Germany and the USA started these investigations. The aim was to determine the most rational, constructional parameters of working elements, providing the best agricultural and technical indexes, and to check their efficiency in comparison with the other kinds of rotary hillers. Analyzing working elements of tree types (cutting, friable, hoe-mattock), Gallwitz and Breitfuss determined that cushioning S-cutters have less duty. W. Adams concluded that largely the surface speed of knife’s points of working elements affects on the power capacity amount, required for milling. German scientists, (В. Zоnе) and R. Til studied fifteen kinds of working elements and the geometry of chips according to the angular velocity of the roller and the speed of progressive motion of the aggregate. They also proved experimentally the scheme of placing working elements on the roller, providing the stability of amount of resisting moment. S. Gaveles studied some questions of rotary hiller’s kinematics and influence of working elements on the amount of spent energy. Theoretical and experimental researchers of milling process present the important interest. German scientist W. Myrchem, English scientist С. Volfe, Japanese scientist Matsuo, Polish scientist G. Bernatsky, made these researchers.

The main attention of foreign scientists directed to experimental researchers of rotary hillers, proving their constructive and kinematic parameters. Nowadays there are many working elements of different types for rotary hiller’s constructions, which are satisfied soil and climate conditions for each country. Four types of springs for working elements were created for lawn-and-garden and farms in the USA, and it was arranged the issue of ripper and cutting knives for field conditions. In Germany, the most popular working elements are of S-form, in Holland, Italy – L and T-form f knives, in Japan more applied vertical rotary hillers with smooth bend and spiral turn of knives relatively to the plane of rotation. The experience of productive exploitation of rotary hillers revealed their agricultural, technical and economic advantages, which helped to organize the manufacture of these machines. At present many countries, produce rotary hillers of different capacity from one to 250 kW.

The rotary

hiller “Rotavator” had a wide distribution on the preplant work in countries of

Western Europe. Howard Company, which produces more than 10 modifications for

different purposes, made this kind of rotary hiller; there are four series

depending on tractor capacity and type of soil (table 1). German company, «Kuhn»,

also produces a wide range of rotary hillers meaning for various work

conditions: series EL and DK – horizontal placing of the roller

(table 1).

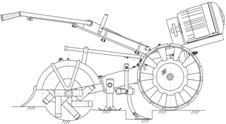

Furthermore, for working inside hothouses and on lots near houses many of foreign countries (USA, Italy, Japan, England and others), and also Russia produce compact self-propelled rotary hillers (table 1) with driving wheels and without them.

High intensity of working parts and units of machine, high speed of interaction with soil, tendency to decreasing power intensity and specific quantity of metal demand from scientists to create more precise methods of calculations of working elements and parts of transmission, taking into consideration statistic and dynamic loads.

«Old age» and «death» of technical system. The main content of this stage is regulation of system parameters. At the beginning of the stage, we can see not great gain, and then it became practically insignificant, in spite of the fact that embedding of force and means were increases. The complexity and scientific work are quickly increasing, and even little improvement of parameters demands of serious researching. At the same time system efficiency is still high, because even little improvement multiplies by mass issuing, can be effective. Driving force at this stage is social need. However, for some systems, it could be satisfied by achieved level and it would not

Table 1 – Basic structure of tillage cutters

|

Name, manufacturer |

General view of the machine |

Note |

|

Cutter "Rotavator" P-Series Manufacturer: Company «Howard», United Kingdom |

|

Pre-sowing treatment in Western Europe |

|

Cutter DK series with horizontal frezbarabanom manufacturer: firm «Kuhn», Germany |

|

Pre-sowing treatment in Western Europe |

|

Self-propelled motofreza peremeschaemae by the reaction of cultivated soils, producer: Russia |

|

Milling of medium and heavy soils in personal subsidiary, farm, greenhouse and other farms |

|

Self-propelled motofreza moved by the drive wheels, the manufacturer: Russia |

|

Milling of medium and heavy soils in personal subsidiary, farm, greenhouse and other farms |

have the necessity to be improved. In this case, social expenses decrease, as they connect with trying the perfection. The reproduction of the system could be cheap enough, and what is more, expenses on it would decrease due to increasing the general level of technology.

Rotary hillers, according this analyze [12], which presents here partially, are at the second stage of above-mentioned law of development of technological systems.

2. Main tendencies of rotary hiller’s development

Insside each stage of development, technical systems develop according their laws. These laws were discovered by some scientists [3]. Genrich Altshuller, he formulated 8 conditions of development of technological systems, which he divided into three groups: statistics, kinematics and dynamics. Е. P. Balashev formulated regularity of perfecting the functional and structural organization of technical system; law of relational and temporal solutions of contradictions in anthropogenic systems; regularity of increasing functional, structural, energy, information integrity of system; principle of multi-functional systems; regularity of adequate and structural organization of system; regularity of associativity of system’s qualitative factors. А. E. Polovinkin formulated principle of excessiveness of technical solutions; principle of correspondence between functions and technical solutions; principle of relative existence of functions and technical solutions; principle of constructive evolution; principle of inertia in the manufacturing field; general accordance between functions and structure of technical objects; hypothesis about progressive constructive evolution of technical objects. Hereinafter we hold to laws by Genrich Altshuller, as the most justified, objective and recognized by reseach community.

Statistics laws, including: 1) the law of complement of system parts; 2) the law of system «power conduction»; 3) the law of rhythmic concordance of system parts.

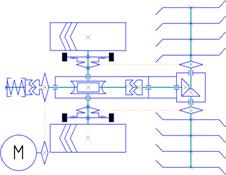

1. The law of complement of system parts consists of necessity to keep conditions of principle viability of technical system – presence and minimal working capacity of main system parts. Each technical system has to include four basic parts: engine, transmission mechanism, working element and operating control. If we take a rotary hiller, even the first models fully completed this law (engine, gears, knives and operating control).

2. The law of system «power conduction» includes the necessity to keep conditions of straight-through power passage along all system parts. Any technical system is a transformer of power. The necessity of power transfer from an engine through transmission to working elements is evident. The transfer of mechanical motion from engine to knives and traversing wheels realize by driving gear.

3. The law of rhythmic concordance of system parts, according to the rhythmic (frequency of oscillation, periodicity), all system parts are realized in a rotary hiller as the work synchronism of all parts (engine, driving gear, knives and traversing wheels).

Kinematics laws (the law of increasing a degree of an ideal system, the law of uneven development of system parts, the law of the transfer to the super system).

4. The development of all systems directs to increasing the degree of the ideality. An ideal technical system is a system, weight, volume and surface of which vanishes, but its capability to work does not decrease. In other words, an ideal system – when there is not any system, and its function keeps and realizes. Applying to the rotary hiller, efforts of antecedent, present and future researchers direct to the solution of these problems.

5. The law of uneven development of system parts. The development of system parts is uneven, if a system is more complicated, it means, its part development is more uneven. It can be a cause of an origin of technical and physical contradictions, and then inventor tasks. There are some examples of the law demonstrations in the development of rotary hillers. The first is decreasing total weight of its construction, which can be a cause of unstable motion of a machine, and as the consequence – worsening of tillage quality. The second is modernization of engines, driving gear and all mechanical parts, the lack of operating working modes, adapted to the environment (soil state).

6. The law of the transfer to the super system. Exhausted potentialities of development, a system is included in the super system as one of its part; and following development will be at the level of the super system. So, rotary hillers with a steam engine was improved to rotary hillers with an internal combustion engine, and then to rotary hillers with electric and hybrid engines.

Dynamics laws consist of: 7) the law of development in the direction of increasing a degree of controllability; 8) the law of increasing a degree of breakage, dispersibility of working elements; the law of increasing a degree of OBACT (object and action). The development of technical systems passes from macro level (of systems, consisting of complex subsystems, parts of complex form) to micro lever (systems, using physical effects, connected with substance construction). In accordance with these laws, the development of technical systems is passing in the following turn:

– from a system with constant parameters to systems with parameters, changing due to changes of its work modes, providing its optimal functioning (rotary hillers with manual, manual-automatic and automatic changes of work modes [4, 5, 6, 15, 18] (table 2), depending on changes of soil state);

– from narrow functional systems, intended to solve concrete problems, to wide functional systems, permitting to change functions of rearrangement, for example, combined rotary hillers can have some technical operations [11, 12, 13, 14]: milling-harrowing, tillage-planting, tillage-fertilizer application, tillage-harvesting and others;

– to systems with differential inside conditions. There is the rotary hiller’s division of power current from the engine [4, 5, 18] on the rotation of knives and running wheels (table 2) and others. At the time when conditions on «enter» and «exit» of a system are determined by the environment and the human (changes of physical and mechanical characteristics of soil, features of the area and others);

– to systems with increasing parameter of freedom, flexible, elastic, for example, transfer from fixed knives to knives with regulated cutting angle [4, 5, 8, 9, 10, 16] (table 2), providing decrease of power intensity of cutting process up to 30 % and others;

– to systems with changing connections between elements, knives with changing grasp width [17], depending on soil state (table 2), providing the decrease of productivity 1,5 times and others;

– from systems with statistic stability to systems with agile stability, that is only due to operation, for example, using flywheel accumulator energy in a rotary hiller [13] (table 2), providing not only stability of its action, but also regularity of work, etc.;

– for using self-programming, self-studying, self-recoverable systems, using adaptive rotary hillers with automatic regulation of work modes, depending on soil consistence [14, 18] (table 2), providing regularity of rotary hiller’s load, increasing its productivity and decreasing work power intensity and others. Consequently dynamic and controllability of technological systems develop objectively and upward, from lesser to bigger.

Table 2 – The manifestation of the laws of dynamics on the example of the PF

|

№ p/p |

Name, manufacturer |

General view of the machine |

Note |

|

1 |

PF prototype with manual speed control through a V-belt CVT (patent number 144732 Russian Federation "self-propelled cutter tillage" |

|

Operation mode is selected speed control milling using a V-belt CVT |

|

2 |

Prototype tillage cutter with automatic speed control (patent number 2,340,134 of the Russian Federation "Cultivation elektrofreza" |

|

Operating mode is selected automatically control the speed of the cutter using the tracking device |

|

3 |

Utility model patent of the Russian Federation № 134 731 "Self-propelled combined tillage machines" |

|

When working mills combined tillage passive (cultivators paws) and active (milling) working bodies |

|

4 |

The prototype multi-mode PF with a working body with a constant cutting angle (patent number 2,519,883 of the Russian Federation "working body tillage cutters") |

|

In tillage cutter provides optimal conditions of soil cutting chips due to the constancy of the cutting angle |

|

5 |

Prototype milling cultivators with adaptive working body (utility model patent of the Russian Federation № 142444 "working body milling cultivators") |

|

By controlling the width of milling working by installing or removing the working sections provide the most full load engine |

|

6 |

Patent the invention of the Russian Federation Number 2243633 "Cultivation cutter" |

|

Work flywheel energy storage provides stabilization of the engine cutter, and there are reactive time improves the stability of the working bodies of the milling depth |

9. The law of increasing a degree of OBACT. Genrich Altshuller [1] formulated this law. OBACT means interaction a substance and a field (different field, for example – gravity, magnetic, power and others), here regularity displays in the development of systems, which directs to increase of a degree of OBACT, in this case – additional using in rotary hiller vibration, electromagnetic and other fields).

3 Conclusion

Consequently, accomplished analyze of rotary hiller’s history allows us: first, to determine the stage of development of rotary hillers, this is a second stage, which assists the necessity in subsequent modernization and expansion of their usage. Secondly, it helped to uncover directions of its development in the historical perspective: 1) modernization of driving gear (steam, internal combustion engine, electrical, hybrid, others); 2) modernization of working elements (optimal form of knives, controllability of gasp width, controllability of cutting angle and others); 3) functional increasing (providing movement stability, using flywheel accumulator of power, operating cutting modes, adaptation to changes of environment , combination of technological process and others). Thirdly, it stimulated to find perspective directions of rotary hiller’s perfection due to adaptive approach when we choose optimal constrictive and technical parameters and working modes of rotary hillers according to soil conditions and required quality of soil cultivation.

2. Naumkin N. I. Fundamentals of engineering creativity: the textbook / N.I. Naumkin, E.P. Groshev, A.N. Lomatkin, V.F. Kupryashkin; under the total. Ed. P.V. Senin, N. I. Naumkina. - Saransk: Publishing House of the muzzle. University Press, 2009. - 188 p

3. Basis of innovative engineering / N.I. Naumkin, E.P. Groshev, A.N. Lomatkin, N.N. Shekshaeva; edited by P.V. Senin and N.I. Naumkina - Saransk Univ Mordovians. Univ. - 2012. - 276 p.

4. A.S. Knyazkov Improving the efficiency of tillage cutters by changing the angle of attack of the knife / A.S. Knyazkov, V.F. Kupryashkin, N.I. Naumkin, E.A. Bobrovskaya .// Journal of the Kyrgyz-Russian Slavic University. - 2013. - T.13. - № 7. - pp 47-53.

5. Kupryashkin V.F. Improving the efficiency of the self-propelled cutter compact tillage optimization design and technological parameters (for example, milling FS-0.85): Author. dis. ... Cand. tehn. Science / V.F. Kupryashkin. - Saransk, 2011. – 20 p.

6. Kupryashkin V.F.-propelled small-sized cutter // V.F. Kupryashkin Rural mechanic. - 2013. - № 12. - S. 4 - 7.

7. Kupryashkin V.F. Optimal mode milling soil / V.F. Kupryashkin, N.I. Naumkin, A.V. Bezrukov // Rural mechanic. - 2010. - №11. – S. 8 -10.

8. Naumkin N.I. Synthesis of planetary mechanisms of high-tech agricultural machines by their identification with lever / N.I. Naumkin, V.F. Kupryashkin, A.V. Princelings // Volga Niva. - № 4 (17). - 2010. P. 45 47.

9. Naumkin N.I.. Theory of mechanisms and machines and its application in agriculture: the Textbook / N.I. Naumkin, V.F. Kupryashkin, N.V. cancers; under the total. Ed. P.V. Senin, N. I. Naumkina. - Saransk: Publishing House of the muzzle. University Press, 2012. - 220 p.

10. Naumkin N.I. The effectiveness of tillage cutters with adjustable angle of attack of the knife / V.F. Kupryashkin, N.I. Naumkin., A.S. Princelings // Tractors and farm machinery. 2013.- № 10. - S. 36-38.

11. Surin E.V. Combined working bodies in small machines / E.V. Surin, V.F. Kupryashkin, N.I. Naumkin, A.V. Bezrukov, A.S. Mitin // Rural mechanic. - 2011. - №6. - P. 6-7.

12. Surin E.V. Use of combined working organs in small self-propelled tillers / E.V. Surin, N.I. Naumkin, V.F. Kupryashkin, M.N. Chatkin, A.V. Bezrukov // Tractors and farm machinery. - 2012. - №10. - S. 11 -13.

13. Patent 2243633 Russian Federation, IPC A 01 B 33/00, 33/08. Cultivation cutter / M.N. Chatkin, V.F. Kupryashkin, N.P. Panfilov, N.I .Naumkin; applicant and patentee Mordovia State. Univ. - № 2003103179/12; appl. 03.02.2003; publ. 10.01.2005, Bull. № 1. - 4. : Ill.

14. Patent 2340134 Russian Federation, IPC A 01 B 33/02. Cultivation elektrofreza / V.F. Kupryashkin, N.I. Naumkin, A.V. Bezrukov; patentee VPO "Moscow State University N.P. Ogareva. "- № 2007117644/12; appl. 11.05.2007; publ. 10.12.2008, Bull. № 34. - 5 seconds. : Ill.

15. Patent 134731 Russian Federation, IPC A 01 B 39/10. Self-propelled combined tillers / V.F. Kupryashkin, A.V. Mitin, N.I. Naumkin, A.G. Kapustin, M.A. Kupryashkin, I.V. Eremkin; patentee VPO "Moscow State University N.P. Ogarev. "- № 2013129838/13; appl. 28/06/2013; publ. 27.11.2013, Bull. № 33. - 2. : Ill.

16. Patent 2519883 Russian Federation, IPC A 01 B 33/08. The working body tillage cutter / N.I. Naumkin, A.S/ Knyazkov, V.F. Kupryashkin; patentee VPO "Moscow State University N.P. Ogarev. "- № 20131205923/13; appl. 05/06/2013; publ. 20.06.2014, Bull. № 17. - 7c. : Ill.

17. Patent 142444 Russian Federation, IPC A 01 B 33/00. The working body of the milling cultivators / V.F. Kupryashkin, A. G. Kapustin, N.I. Naumkin, A. F. Ulanov; applicant and patentee VPO "Moscow State University. N.P. Ogarev. "- № 2014106691/13; appl. 21/02/2014; publ. 27.06.2014., Bull. № 18. - 2. : Ill.

18. Patent 144732 Russian Federation, IPC A 01 B 33/02. Self-propelled cutter tillage / V.F. Kupryashkin, N.I. Naumkin, A.F. Firstov patent VPO "Moscow State University N.P. Ogarev. "- № 2014117593/13; appl. 04/29/2014; publ. 27.08.2014, Bull. № 24. - 2. : Ill.

Kupryashkin V. F., Naumkin N. I., Grocheva E.P., Panyushkina E. N. HISTORY OF DEVELOPMENT OF TILLAGE CUTTERS. International Journal Of Applied And Fundamental Research. – 2015. – № 2 –

URL: www.science-sd.com/461-24928 (28.02.2026).

PDF

PDF