About Us

Executive Editor:Publishing house "Academy of Natural History"

Editorial Board:

Asgarov S. (Azerbaijan), Alakbarov M. (Azerbaijan), Aliev Z. (Azerbaijan), Babayev N. (Uzbekistan), Chiladze G. (Georgia), Datskovsky I. (Israel), Garbuz I. (Moldova), Gleizer S. (Germany), Ershina A. (Kazakhstan), Kobzev D. (Switzerland), Kohl O. (Germany), Ktshanyan M. (Armenia), Lande D. (Ukraine), Ledvanov M. (Russia), Makats V. (Ukraine), Miletic L. (Serbia), Moskovkin V. (Ukraine), Murzagaliyeva A. (Kazakhstan), Novikov A. (Ukraine), Rahimov R. (Uzbekistan), Romanchuk A. (Ukraine), Shamshiev B. (Kyrgyzstan), Usheva M. (Bulgaria), Vasileva M. (Bulgar).

Engineering

Summary

Analysis of existing methods of heat treatment of thin –walled products by the example of saw blades of cotton gins in Russia, the USA and Germany has been carried out. New technology of improving the service life of these products was developed . The influence of nano structure on the wear resistance has been found, calculation of stresses, arising during heat treatment of saw blades, has been done. Their wear resistance at treatment according to the new technology is 2 - 3 times greater than the wear resistance of saws, treated by the known (basic) technology. For the manufacture of saw blades instead of instrument steel 48Г it is possible to use the cheaper steel 65Г, reinforced according to new technology,. The new way to improve the service life of saw blades does not require capital expenditures for the purchase of special equipment and can be easily implemented on the now acting installations of high frequency current (HFC).

Keywords: strength, hardness, wear resistance, nanostructure, heat treatment, saw blades, stress, troostite, sorbite, bainite, phase transformations.

Introduction. The developed heat treatment technology has been applied to increase the service life of saw bladesof cotton cleaning machines and can be used in agricultural engineering (hardening of disks of tillage combines and sowing units), as well as in tool production (hardening of disk cutters) and in wood processing industry (hardening of circular knives). At cotton gin plants for processing the raw cotton the gin and linter toothed saw blades with outer diameter - 320 mm, internal - 61mm and a thickness of 0,95mm are widely used. The teeth of saw blades during operation are subjected to abrasive wear and get out of order while in service, that is why the annual production of gin and linter saw blades for cotton cleaning machines reaches several millions of pieces. To improve the service life these products are heat-treated.

At hardening saw blades thevolume and induction hardening (HFC) are applied. Carbon instrument steelsУ8Гwith hardness HRA 67-70are applied to manufacture these products. Despite increased hardness, the lifetime of saw bladesis insufficient. In connection with this annually for the manufacture of saw blades several hundred tons of extremely expensive steelУ8Гareused up. Further increase of wear resistance through the use of steel of higher hardness is not possible because of the difficulty of machining (cutting-out of discs, teeth notching).

Choice of material and technology of hardening to the required level of wear resistance, maintenance of flatness of saw blades during heat treatment and reduction of their cost is an actual problem.

Objective: increase of wear resistance of saw blades of cotton cleaning machines.

Tasks: - analysis of the existing heat treatment methods of saw blades inRussia, the USA andGermany;

-development of new hardening technology of thin-walled steel products

(saw blades);

- identification of the role of nanostructure on wear resistance of saw blades;

- calculation of stresses, generated during the heat treatment of saw blades;

-study of wear resistance of pre-hardened saw blades both according to basic and new technologies of heat treatment.

Materials and methods of study.

Saw blades made of steel У8Г and 65Г. Metallographic and X-raystructure analysis, test methods on wear resistance, computers to calculate the stresses,occurring from heat treatment of thin-walled steel products, are used.

Results of the work. During the operation of saw blades on the side surfaces of teeth the tracks of "plowing "areformed by hard abrasive particles, which results in blunting of edges and tips of saw teeth. Presence of abrasive particles is due to dustiness of raw cotton by particles of sand (silica) and alumina.(Fig.1).

Saw blades of different manufacturers (Russia, the USA, Germany) have been studied.

The structure of saws of American production is perlite, which differs by the degree of dispensability of cementite particles , hardness HRC 22-24. (Figure 2a).Analysis ofthe state of thematrix (of the base) of the saw blade has found that these products were subjected to cold plastic deformation (hammering harden) with higher level of dislocation density.

Structure of saw blades ofGermanyproduction consists of lamellarperlite with a small inclusion of ferrite. Such a structure is formed at normalization with hardness HRC26-28. (Fig.2б).

Structure of saw blades of Russian production has a troostite - sorbitol granulated structure, although there are areas of pearlite ofsheet-like nature, formed at the improvement (thermo hardening plus high-temperature temper). (Fig.2в).

The mentioned methods of hardening do not provide high abrasive wear resistance of products because of the low density of nanostructure (of dislocation).

For manufacture of saw blades instead of tool steel У8Г it is possible to use cheaper steel 65Г, hardened by known (Russian)technology and technology, developed by us.

New method of hardening is preliminary heating of saw bladesupto 400-450 ° C followed by 3-fold electro thermo cyclic treatment (ETCT) in the temperature range of 920-700 ° C, hardening and tempering at 250-300 ° C in a specially designed fitting-out [1, 2]. Heating upto 400-450 ° C was carried out in order to reduce heat stresses during subsequentETCT. Grinding austenite grains and increasing the dislocation density is achieved as the result of multiple phase transformationsat triple ETCT. After hardening from the last cycle of heating ETCT fine-needled marten site is formed with a maximum density of dislocation, which after tempering 200-250 ° C passes into bainite structure (hardness HRC 40-42) (Fig.2г) .

It is known that the increase of defects presence (dislocation) of metal lattice increases the wear resistance. Influence of the finestructure ofthe alloy (nanostructure) on wear resistance of steel is so significant that with increasing density of dislocations the abrasive wear resistance of surfaces of steel products increases [3].

a)  b)

b)

Fig 1. Microstructure of steel Y13

a – after hardening by HFC; b – after ETCT + IPT;

a)  b)

b)

Fig 2. Dislocation structure of steel Y13(found out by method of etch pits)

a – after ETCT b – after ETCT + IPT

a) b)

b)

Fig 3. Dislocation structure of steel Y13(electron microscopy)

a – after ETCT b – after ETCT + IPT

The density of dislocations was determined by X-ray diffraction along broad ending lines of interference of X-ray patterns, depending on the reflection angle (θ). To calculate the density of dislocations (ρ) the following ratio was used [4]:

ρ=β²/2b²×ctg²θ

Where: β– physical width of the X-ray lines;

b – Burgers vector (for VCCLб = 0.25mm);

θ- angle of reflection.

Saw blades, which have passed hardening both according to the basic and new technologies, were tested for wear resistance in a special unit, that simulates the products’ operationat cotton cleaning machines. The essence of the test is that a pile of saw blades is mounted on the shaft and imbedded by ¼ of the diameter of the saw blade into a sand bath. Theshaft speedis 750 rev / min and corresponds to the speed of rotation of saw blades in the cleaning machine, the test time is from 10 to 80 minutes. Before the test the measurements of height of the saw teeth in four mutually perpendicular directions to diameter were carried out. Wearrate was judged by difference in the heights of the saw teeth before and after the test. The results are presented in table1.

Density of dislocations, hardness, wearrate.

|

№ |

Steelgrade |

Type of hardening |

Density of dislocation ρ * 10¹¹1 /cm² |

Hardness HRC |

Wear, mm |

|

1

2

3

4

|

SteelУ8Г

Steel 65Г

SteelУ8Г

Steel 65Г |

Basic technology (hardening, high –temperature tempering)

Вasic technology (hardening, high temperature tempering)

New technology (preliminary heating, ETCT)

New technology (preliminary heating ,ETCT) |

2,15

2,10

3,60

3,55

|

34-36

32-34

42-44

40-42 |

0,36

0,40

0,15

0,20

|

From Table 1 it follows that steels У8Г and 65Г, which have passed hardening according to the new technology (pre-heated to 400-450 ° C and subsequent ETCT), have a higher hardness, dislocation density and low amount of wear compared to the basic technology (hardening HFC plus high-temperature tempering).

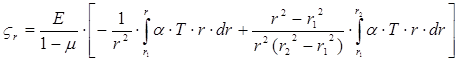

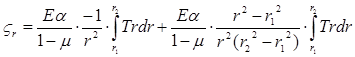

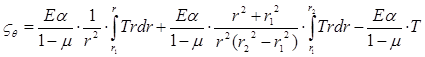

Calculation of thermal stresses was done according to well-known formulae for heavy-walled cylinders having different temperature of inner and outside surfaces. Since the thickness (height) of the cylinder is small (0,95mm) values of radial and circumferential (tangential) stresses were found according to equations:

(1)

(1)

. (2)

. (2)

In these formulae:

E -elasticity modulus

μ - Poisson's ratio,

r¹ - inner radius of the saw(holes) - 30 mm,

r² - outer radius of the saw - 160 mm,

α - temperature coefficient of linear expansion,

T –temperature of thesaw in the studied point of radius ,

r –shifting radius .

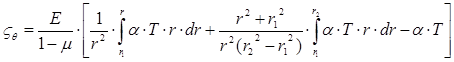

Necessary data for calculation about the parameters, properties of steels at various temperatures were taken from the reference manual [5]. Since a number of parameters and properties of steels at the change of temperature change quite significantly, the formulae (1) and (2) were rewritten in the form of :

, (3)

, (3)

. (4)

. (4)

Measurements of the temperature along the points of the saw radius showed that distribution of temperatures can be represented as a broken line. In general this corresponds to the adopted method of calculation, when the change of temperature from the hotter one, is considered approximately to be a linear one. So thegeneral definite integral in the formula (3.4)was calculated as the sum of ratios, limited by a certain section of right line of change of temperature, depending on saw radius. On each temperature section the changes of the elasticity modulus and coefficient of linear expansion were takeninto account. Structural and thermal stresses in the peripheral zone were calculated in accordance with the volume changes, caused by hardening cooling [6].

The occurring stresses(stress diagrams )were built according to data of computer calculations. The basic idea was to provide in the process of heat treatment the temperature conditions (outside the hard enable zone), excluding the occurrence of stresses above the flow limit.

Induction impulsive heating of saws at the saw gull let up to temperature of 900 ° C under linear distribution of temperatures along the radius, means that the total heating zone of the saw along the radius reaches 8mm from gullets. At the same time at the depth up to 2 mm the heating takes place above A3 (austenitic state), but at the depth of over 2 mm the temperature isbelow thepoint of phase transformation. The distribution of temperatures and occurring internal stresses are presented in tables (2,3). Integral Trdr is computer calculated , using numerical methods, in particular the methods of rectangles or trapezoids. [7]

Radial stresses in the sawframe at heating the peripheral zone by high frequency current (HFC).

Table 2

|

Radius from saw axis to periphery, mm |

Radial stresses σ, MPa |

Radius from sawaxis to periphery, mm |

Radial stresses σ, MPa |

||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||

|

70 |

90,06 |

145 |

105,64 |

|

75 |

92,70 |

150 |

105,94 |

|

80 |

94,86 |

152 |

106,13 |

|

85 |

96,62 |

154 |

94,57 |

|

90 |

98,09 |

156 |

69,48 |

|

95 |

99,37 |

158 |

45,66 |

|

100 |

100,45 |

160 |

0,00 |

Tangential stresses in the saw frameat heating theperipheral zone byinduction method

Table 3

|

Radius from saw axis to periphery, mm |

Tangential stresses, σ MPa |

Radius from saw axis to periphery, mm |

Tangential stresses, σ MPa |

|

30 |

220,79 |

105 |

119,36 |

|

35 |

191,49 |

110 |

118,58 |

|

40 |

172,48 |

115 |

117,89 |

|

45 |

159,44 |

120 |

117,30 |

|

50 |

150,13 |

125 |

116,71 |

|

55 |

143,18 |

130 |

116,22 |

|

60 |

137,98 |

135 |

115,83 |

|

65 |

133,86 |

140 |

115,44 |

|

70 |

130,63 |

145 |

115,05 |

|

75 |

128,09 |

150 |

114,75 |

|

80 |

125,93 |

152 |

144,66 |

|

85 |

124,16 |

154 |

-793,01 |

|

90 |

122,59 |

156 |

-1909,23 |

|

95 |

121,42 |

158 |

-1990,62 |

|

|

|

160 |

-3776,92 |

In the heating area the tangential stresses by fargo beyond the yield strength of steel both in the area of austenitic state and in the area of temperatures below the phase transformation. In the austenitic area relaxation of stresses must take place, although as it will be shown below, a very fast impulsive heating during 0,8sec leaves stresses 250-450 MP aun relaxed. If to take into account that at 240-350 ° C the yield strength of steel У8Г in the state as received does not exceed 1000 MPa, it turns out that at the depth of up to 6 mm from the gullets the stresses exceed the yield strength . Consequently, plastic deformation and stress relaxation will take place. After hardening cooling the reduction of volume occurs due to the martensitic transformation. At other depths there is no such compensation and during cooling contractions are inevitable. The experiments confirmed the calculations – all saws after such heat treatment had a "bend in the form of adish "up to 3-4 mm.

Subsequent straightening of saws is also unlikely because it is only possible during tempering of chilled steel under stress at sufficiently high temperature. In tempered or hot- rolled state (i.e. in areas deeper than 2 mm from saw gullets)thesteelsУ8Гare difficult to straighten. In case of treatment of saw blades according to new technology thestresses do not exceed the yield strength of steel У8Г (1000MPa) and deformation (contraction) of products is in significant and is with in the pink limit.

Conclusion.

1. The principles of hardening saw blades of various countries-manufacturers (Russia, the USA and Germany) have been studied.

2. Calculations of stresses, occurring from the electro thermal treatment of saw blades,arepresented.

3. A new technology of wear resistance increase and manufacture of defect-free saw blades of cotton cleaning machines have been developed.

4. Wearresistance of saw blades, subjected to processing according to the new technology is 2-3 times higher than the wear resistance of saw blades, treated according to basic technology

5.To manufacture saw blade instead of instrument steel У8Гit is possible to use cheaper steel 65Г, hardened according to the new technology.

6. The new method of hardening saw blades does not require expensive special equipment and can be easily implemented on the now existing induction units (HFC).

2. Islamkulov K.M., Kolmykpayev B.H.An apparatus for induction hardening. RK patent for invention, number 18630, Bull. № 5, 2010y.

3. DyachenkoS.S.Heeredity in phase transformations: mechanism of the phenomenon and influence on properties .// Metal science. Heat Treatment of Metals ,2000, №4, pp.14-19.

4. IvanovA.N., Klimanek L., Polyakov A.M. Research of substructure of metalsby X-ray method. // Metal science. Heat Treatment of Metals 2000, № 8, pp.7-10.

5. Reference book in engineering materials. MashkizM., 1979y, Volume 1, p.507.

6. Zenkin A.S., ArsentyevB.M.Fit-up of fixed joints by thermal methods.M., Mechanical Engineering, 1987, p.125.

7. Bermant A.F.,Aramanovich I.G. Short course of mathematical analysis. Nauka, Moscow, 1973, p.712.

Islamkulov K.M., Myrkhalykov Zh.U., Aymenov Zh.T., Suvorov A.S. IMPROVEMENT OF SERVICE LIFE OF THIN-WALLED STEEL PRODUCTS BY THE EXAMPLE OF SAW BLADES. International Journal Of Applied And Fundamental Research. – 2016. – № 1 –

URL: www.science-sd.com/463-24975 (31.01.2026).

PDF

PDF