About Us

Executive Editor:Publishing house "Academy of Natural History"

Editorial Board:

Asgarov S. (Azerbaijan), Alakbarov M. (Azerbaijan), Aliev Z. (Azerbaijan), Babayev N. (Uzbekistan), Chiladze G. (Georgia), Datskovsky I. (Israel), Garbuz I. (Moldova), Gleizer S. (Germany), Ershina A. (Kazakhstan), Kobzev D. (Switzerland), Kohl O. (Germany), Ktshanyan M. (Armenia), Lande D. (Ukraine), Ledvanov M. (Russia), Makats V. (Ukraine), Miletic L. (Serbia), Moskovkin V. (Ukraine), Murzagaliyeva A. (Kazakhstan), Novikov A. (Ukraine), Rahimov R. (Uzbekistan), Romanchuk A. (Ukraine), Shamshiev B. (Kyrgyzstan), Usheva M. (Bulgaria), Vasileva M. (Bulgar).

Engineering

Introduction

Development of scientific basis of the electromagnetic method of mechanical activation in view of the provisions of the physico-chemical and energy theories of fracture of solids under the action of external loads - a problem of great practical significance. Evidence-based systematic approach to process optimization in EMMA allows significant savings in the design of the new model series devices to the specified output. Study patterns of mechanical activation is necessary for the design of new structures mechanical activators, determination of optimal conditions and increase the efficiency of their work, the choice of hardware and rational technological schemes of processing of raw materials into finished products [1,2,3].

The determining factors that characterize the process of grinding, mechanical activation of materials electromagnetically, are the energy costs of the process in experimental determination of the optimal mode of operation of the electromagnetic mechanical activators (EMMA), in which the finished product output has established technological requirements fineness at a high rate uniformity of its particle size distribution [4,5,6].

The objective of the work:

The object of research is a natural product processing in electromagnetic mechanical activator with justification energy efficiency of their work in the technology hardware and agribusiness lines.

The material and methods of the investigation:

Dependencies energy EMMA considering the physical and mechanical properties of the processed materials.

The results of the investigation and discussion about them:

As the dispersion characteristics of the product it is advisable to take a specific surface area, and as activator characteristics - the energy transferred to them per unit mass of material or energy consumption per unit of surface area formation of the ground product. According to studies [7,8,9], if the attribute of energy costs, running directly on the milling (energy consumed EMMA with a refining material, less energy consumed for the organization of the grinding force), the dependence of the specific surface of the solid components of the cost of such useful energy consumed is independent of the weight of the crushed product. Meanwhile, the absence of this relationship holds only if the impact force exceeds a certain grinding elements, the grinding material characteristic value minimally required to break the largest particles, that is, if EMMA works in optimal speed and electromagnetic modes [10,11,12] the crushed product.

The specific energy of grinding products in EMMA is determined by the formula [1]:

, (1)

, (1)

Where ![]() the total surface area of the processed product, m2 / kg;

the total surface area of the processed product, m2 / kg;

ЕМ - Bringing energy kJ / kg,

![]() , (2)

, (2)

where the organization of the working process РОБ - power grinding effort;

РПР - power grinding process components electromagnetically;

t - time of grinding, min.

The specific surface area of the material multifractional calculated by multiplying the surface area fraction corresponding to its number, followed by summing over all factions:

![]() , (3)

, (3)

where е1, е2,…еi specific surface separate monofractions;

![]() – percentage of mono fractions of crushed components.

– percentage of mono fractions of crushed components.

The surface area of the individual fractions is determined from the equation:

![]() , (4)

, (4)

where Ром - density of the processed product, kg / m3;

δ - size fractions, m.

For the mathematical description of the process of fine and ultra-fine grinding in EMMA energy theory holds Rittinger:

![]() ,

,

, (5)

, (5)

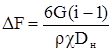

where ΔF- gain new surface, m2;

k - coefficient of proportionality, equal to the work expended on the formation of a new surface;

G - performance;

i - crushing;

ρ- bulk density of the powdered product;

χ- form particulate material factor (table value);

Di-initial size pieces.

To assess the energy efficiency of the proposed method of mechanical activation in the design type series of electromagnetic actuators is advisable to use a parameter of efficiency - the ratio of useful results achieved by milling the total energy costs, achieved in the working volume of the machine:

![]() ,

, ![]() ;

;![]() , (6)

, (6)

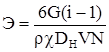

where V- mehanoaktivatora working volume, m3;

N - work expended per unit time, J.

Growth efficiency parameter indicates the new surface unit per unit volume per unit of work per unit time.

In view of formula (6.6) Energy efficiency:

, (7)

, (7)

![]() (8)

(8)

where  ,

, ![]() - a quality criterion.

- a quality criterion.

Display power efficiency (6.8) can be used to compare any kinds of milling equipment (assuming identical materials handling), if it lead to dimensionless form:

, (9)

, (9)

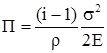

For comparison, the energy efficiency in the implementation of the electromagnetic method of mechanical activation in the presented formula introduced measure the strength of the material П:

![]() ,

, ![]() (10)

(10)

It should be noted that part of the value of the formula ![]() also indirectly characterizes the strength of the material:

also indirectly characterizes the strength of the material:

, (11)

, (11)

where ![]() - the work of destruction of the material volume Vм elastic deformation (σ-strength material Pa, E-Young's modulus, Pa).

- the work of destruction of the material volume Vм elastic deformation (σ-strength material Pa, E-Young's modulus, Pa).

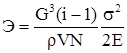

Then the criterion taking into account the increase in the surface area of the crushed material and its strength is:

,

, ![]() (12)

(12)

In the light of the effectiveness of the formulas option is as follows:

. (13)

. (13)

The conclusion

Parameter efficiency grinding process in electromagnetic mechanical activator will be the higher, the larger the surface of the growth will be achieved for a more durable materials with lower energy costs and a minimum working volume of the machine [13,14]. Presented in the article criterial dependences allow to optimize the process of industrial milling on laboratory benches, simulating electromagnetic forming method of dispersing efforts magnetoliquefied ferrotel layer [15,16].

2. Bezzubtseva M.M, V.S.Volkov, V.A.Ruzhev Classification of electromagnetic mills // International Journal of Experimental education - 2015. - № 9. pp.103-104.

3. Bezzubtseva M.M, Intensification of food grinding process // International journal of experimental education. -2016. -№ 5-3. -FROM. 356-357.

4. Bezzubtseva M.M, Obukhov KN The energy parameters characterizing the operation of the electromagnetic mehanoaktivatorov // International journal of experimental education. -2015. -№ 8-1. -FROM. 134-135.

5. Bezzubtseva M.M, Obukhov KN Electromagnetic method of reducing the energy intensity of production in the milling stage // International journal of experimental education. -2015. - № 8-3. -FROM. 399-400.

6. Bezzubtseva M.M, VS Volkov, AV Kotov An innovative way of electromagnetic mechanical activation ferromagnetic elements in magnetic liquefied layer overview // Scientific Review. Technical science. - 2016. - № 2. pp 8-13.

7. Bezzubtseva M.M, On the issue of studying the kinetics of grinding materials in electromagnetic mehanoaktivatorah (EMMA) // International Journal of Experimental Education. - 2016. - № 9-1. - S. 81-82.

8. Bezzubtseva M.M, The equations of the kinetics of dispersion processes in electromagnetic mehanoaktivatorah (EMMA) // International Journal of Experimental Education. - 2016. - № 9-1. - S. 83-84.

9. Bezzubtseva M.M, Energy Efficiency Working conditions of electromagnetic mehanoaktivatorov // International journal of experimental education. - 2016. - № 9-1. - S. 84-85.

10. Bezzubtseva M.M, Volkov V.S, Obukhov K.N, Kotov A.V Determination of forces and moments acting on the grinding system of ferromagnetic elements in a cylindrical shape magnetic liquefied layer overview of the working volume of the electromagnetic mechanical activators // Basic Research. - 2014. - № 11-3. - pp. 504-508.

11. Bezzubtseva M.M, Ruzhev V.A, Volkov V.S Theoretical studies of the deformed magnetic field in the working volume of the electromagnetic mechanical activators with magnetic liquefied layer grinding elements cylindrical form // Basic Research. - 2014. - № 6-4. - pp. 689-693.

12. Bezzubceva M. M., Ruzhyev V.A., Yuldashev R. Z. Electromagnetic mechanoactivation of dry construc-tion mixes. International Journal Of Applied And Fundamental Research. – 2013. – № 2 – URL: www.science-sd.com/455-24165 (16.11.2013).

13. Bezzubtzeva M.M., Volkov V.S., Gubarev V.N. The physical and mechanical processes study in ferro-bodies’ magneto – liquefied layer of electromagnetic mechano – activators (emma) . International Journal Of Applied And Fundamental Research. – 2013. – № 2 – URL: www.science-sd.com/455-24425 (16.11.2013).

14. Bezzubtseva M.M., Volkov V.S. The issue research reliable operation of the with magnetic liquefaction layer. International Journal Of Applied And Fundamental Research. – 2016. – № 1 – URL: www.science-sd.com/463-24972 (20.07.2016).

15. Bezzubtseva M.M, Scientific substantiation of introduction of import substitution method electromagnetic mechanical activation in hardware technology systems chocolate production // International journal of experimental education. - 2016. - № 5-3. - S.351-352.

16. Bezzubtseva M.M, On the question of scientific substantiation of introduction of import substitution method electromagnetic mechanical activation in hardware and technology APC system. In: Scientific support of agricultural development in the conditions of import collection of scientific works of the international scientific-practical conference of the faculty. The Ministry of Agriculture of the Russian Federation, St. Petersburg State Agrarian University. - 2016 -C. 339-343.

Bezzubceva M.M. ASSESSMENT OF ELECTROMAGNETIC ENERGY MECHANICAL ACTIVATORS. International Journal Of Applied And Fundamental Research. – 2016. – № 2 –

URL: www.science-sd.com/464-25168 (11.02.2026).

PDF

PDF