About Us

Executive Editor:Publishing house "Academy of Natural History"

Editorial Board:

Asgarov S. (Azerbaijan), Alakbarov M. (Azerbaijan), Aliev Z. (Azerbaijan), Babayev N. (Uzbekistan), Chiladze G. (Georgia), Datskovsky I. (Israel), Garbuz I. (Moldova), Gleizer S. (Germany), Ershina A. (Kazakhstan), Kobzev D. (Switzerland), Kohl O. (Germany), Ktshanyan M. (Armenia), Lande D. (Ukraine), Ledvanov M. (Russia), Makats V. (Ukraine), Miletic L. (Serbia), Moskovkin V. (Ukraine), Murzagaliyeva A. (Kazakhstan), Novikov A. (Ukraine), Rahimov R. (Uzbekistan), Romanchuk A. (Ukraine), Shamshiev B. (Kyrgyzstan), Usheva M. (Bulgaria), Vasileva M. (Bulgar).

Engineering

The work purpose - studying of physico-mechanical parameters polymeric binding: ED-20 epoxy and synthetic rubbers: butyl rubber (BQ) and siloksane rubber (SKT) with the modifying clays containing 45-55% of oxide of silicon and other oxides, additives and fillers, development of technology of receiving the glue mastics which are strongly sticking together bituminous and ruberoid or synthetic a roof or a sports covering to concrete or other basis and also a possibility of replacement of an expensive kaolin from Russia and Ukraine on clays of local regions of Kazakhstan.

Influence of the nature of fillers is studied: clays of the Turgaysky field of Kazakhstan with the high visco-elastic and knitting properties which are applied to production of a pottery.

In work are applied as binding: solid rubbers: butyl rubber (BQ), isoprene SKI-3, butadiene-styrene CKC-30-APKM-15; butadiene-nitrile SKN-26, butadiene SKD, ethylenepropylene (SKEPT-40), and liquid rubbers: siloksane SKT, nairitovy brands "A", epoxidized PEF-3A and epoxy-ED-20, additives: zinc oxide, a kaolin, aeroforce, stearin, kaptaks, peroxide dikumil, dinitrilazobisizomaslyany acid (DAK), teflon, dye - kubozol blue ''K'', phenolformaldehyde SF-010A pitch, waste of skin and rubber, fillers - various clays, natural Kira.

Hardener - polyethylenpoliamin (PEPA) and the vulcanizing agent - sulfur. Prepared 10% solution of butyl rubber (BR) in Galosh gasoline. Hardening of polymeric systems happened at the room temperature within 24 hours in special forms.

At production of samples on the basis of solid synthetic rubbers previously on laboratory rollers of LB-320 received rubber mixes with curing activators, then added the studied substances to these structures and made curing by sulfur in compression molds at high temperatures.

On the 100 weight. 10% BQ solution took a kaolin - 70, ED-20 - 30, PEPA - 3. The received solution was applied on sub-standard withdrawal - pro-masonry nonwoven fabric of the Kyzyl-Orda factory of nonwoven fabrics, the article 9355141, a drawing layer - 2 mm. In 48 hours prepared a standard sample in the form of shovels and tested by explosive R-500 car in accordance with GOST 2678-87 for determination of physico-mechanical properties and water absorption.

It is shown that this sample has the following physico-mechanical properties: strength on a gap - 6,92 MPas, relative lengthening - 20%, residual lengthening - 12%, and it can be used as a mastic roof.

At reduction of maintenance of a kaolin to the 20th weight part (w.p.) strength on a gap made 5,14 MPa, relative lengthening is equal to 140%, residual lengthening - 32%. Increase in maintenance of a kaolin up to the 130th weight part (w.p.) causes decrease in durability to 2,34 MPa, relative lengthening h - 120%, residual lengthening corresponds to 20%. It is established that with increase in maintenance of a kaolin from 20 to 130 weight part (w.p.) durability of a covering passes through the maximum falling on the 70th weight part (w.p.) kaolin. Relative lengthening also passes through a maximum.

Ashutsky (Turgaysky's) clays (of the field Arkalyk) are used yellow, green and boksitosimilar (red). Composition of mix (in weight part (w.p.): 10% - the BQ solution 100, clay - 40, ED-20 - 50, PEPA - 5, sulfur – 2 р. Strength on a rupture of the mastics containing yellow and green clays in structure practically coincide and 3,8 and 4,2 MPa, relative lengthening - 120%, residual lengthening - 30% are equal, respectively. The structure containing boksitosimilar clay has durability of 1,11 MPa, but higher values of relative and residual lengthenings of 160 and 80%, respectively.

It is found that yellow and green clays promote increase in durability of rubbers. The crushed waste of skin and rubber are studied, it is established that at their equal contents, they cause the following physico-mechanical properties of glue mastics: strength at a gap, respectively, makes 2,98 and 2,28 MPa, relative lengthening: 40 and 70%, residual lengthening - 24 and 12%.

Adhesion of glues to a concrete surface of good 1-3 MPa. It is shown that the glue mastics including as fillers of clay of various fields of Kazakhstan instead of a kaolin, have high physicomechanical rates: strength at a gap makes 3,8-4,2 MPa, relative lengthening - 120-160% that is characterized positively, and it is caused by the knitting properties of clays. Additives of waste of skin and rubber slightly lower strength indicators of mastics, but lead to reduction of values of relative lengthening up to 40 both 70%, and to increase in water absorption that is explained by their low natural knitting and viscoelastic properties.

In Kazakhstan there are large supplies natural Kirov (oilbitumene rocks, 950-1000 million t.), containing natural bitumen in the structure, instead of imported bitumens which can find application in various branches of the construction industry and road construction as the knitting basis for production of facing tiles, bricks, hydrophobic additives, pavings of anticorrosive, warm and waterproofing mastics [7], for creation of the glue mastics and bituminous and ruberoid roofing materials stacked in 4-5 layers. It is known that the bituminous and ruberoid roof possesses low operational characteristics: becomes fragile in the winter, in the summer melts and flows.

As additives are used ED-16 epoxy with PEPA hardener, the SKT siloksanovy rubber, with K-18 hardener - laurilkaprilaty tin, polyethilsiloksanovy liquid (PES-5) - the surface-active substance (SAS), a filler - a rubber crumb. It should be noted that epoxy with siloksanovy pitch practically do not mix up that presents certain difficulties therefore the modifying additives and softeners are necessary.

In work the epoxy composition is use split at 180 ° C Kirov including also SKT, a rubber crumb and softener was received.

This structure has the following physico-mechanical properties: strength at a gap - 1,3 MPa, relative lengthening - 120%, residual lengthening - 20%, water absorption - 0,9% can be also applied as glue mastics and jellied roofing coverings with values of strength on a gap not less - 1 MPa and water absorptions no more than 1% that will be coordinated with requirements of state standard specifications.

The glue mastics applied in construction practice have strength at a rupture of 0,3-1,0 MPa, relative lengthening - 30-50%. High values of relative lengthening also characterize positively properties of mastics as they come nearer to synthetic on the basis of various rubbers.

Compositions of glue mastics and on the basis of synthetic rubbers are developed SKI-3, CKC-30-APKM-15, SKN-26 and the epoxidized PEF-3A rubber which is turning on various modifiers, softeners, additives, hardeners and the vulcanizing agents.

Physico-mechanical properties of this composition No. 20 following:

- strength at a rupture of 4,5-4,6 MPa

- relative lengthening of 462-780%

- hardness on Shora And, 50-55 conventional units.

- elasticity on a rebound, 35-38%

Temperature of curing is 150 °C, time - 45 minutes.

This composition No. 20 at additional introduction of peroxide dikumil, epoxidized rubber, a hardener does not worsen strength indicators, apparently, the synergy effect of peroxide of a dikumil in reaction of initiation and hardening on epoxy groups is shown. Good compatibility of epoksidirovaniy rubber with solid synthetic rubbers is shown.

High elasticity of this structure is caused by the nature of epoxidized rubber which improves the main physico-mechanical characteristics. This structure is optimum for racetracks and can be recommended for laying at stadiums as sports covering [8].

Depending on the nature of clay and addition of the initiator of polymerization of dinitrilazobisizomaslyany acid (DAC) of composition No. 6 and No. 7 on a basis butadiene-nitrile SKN-26 rubber such characteristics, respectively have:

- strength at a gap 1,2-2,1 MPa

- relative lengthening 307-813%

- hardness on Shora And 40-44 conventional units.

- elasticity on a rebound 48-52%.

These compositions No. 6 and No. 7 can be also applied as sports coverings and racetracks [8]. Apparently, oxide of iron is the curing activator along with oxide of zinc and causes passing of an additional stitching on nonlimiting communications of rubber, and DAC promotes polymerization reaction initiation.

It is necessary to assume that only the small part of oxide of iron, being in clay No. 1 and clay No. 2 provides curing of rubber mix, together with other active ingredients: oxide of zinc and sulfur.

The highest durability of 11,6 MPa is reached for mix of SKI-3-100 rubbers weight part (w.p.) and SKS-30 APKM-15-20 w.p. (sample No. 8). The additive of teflon causes decrease in durability to 1,9 MPa, almost by 6 times, decrease in relative lengthening to 550% and increase of elasticity on a rebound from 22 to 70%. Apparently, high durability is explained by the identical nature isoprene and butadiene-styrene rubbers, and process of curing goes with a high speed and selectivity and is not complicated by passing of reaction of hardening on nitrile groups, as in case of SKN-26. Values of hardness of rubbers No. 8 and No. 9, respectively, 47 and 58 conventional units.

Teflon gives compositions on the basis of SKI-3 and SKS-30-APKM-I5 highly elastic properties. The polyethylene additive to isoprene SKI-3, SF-010A rubber and increase in amount of sulfur (sample No. 13) influences strength at a rupture of 0,9 MPa and relative lengthening of 476% as well as addition butadiene-nitrile SKN-26 rubber in isoprene rubber (sample No. 1).

It is established that, despite the lack of a kaolin in composition No. 13 the same durability as at a sample No. 1 is reached, apparently, phenolformaldehyde pitch causes additional curing of rubber mix. CKC-30-APKM-I5 additive in a sample No. 1 causes increase of strength properties to 4,8-5,2 MPa, relative lengthening to 482-550% of value of hardness - 48 and elasticity - 34 (a sample 3). It is found that values of relative lengthening depend on curing time.

Compositions No. 10 and No. 12 on the basis of SKEPT-40 have such high values of durability at a rupture of 2,5-3,0 MPa and relative lengthening of 850-902%. The additive of SF-010A does not influence these properties (sample No. 12). CKC-30-APKM-15 sharply lowers strength properties by 4-5 times to 0,6 MPa and relative lengthening to 60-80%. Apparently, bad compatibility ethylenpropylene is observed here and butadiene-styrene rubbers, negatively influences physico-mechanical parameters.

Compositions with good visco-elastic properties: hardness - 45, elasticity - 50 it is possible to receive on the basis of nairitovy rubber brands "A" at addition of fosforacid aluminum (crystalline hydrate) and clay with the content of oxide of iron of 13% (sample No. 16).

Mix butadiene and butadiene-nitrile rubbers provides high physico-mechanical properties to structures No. 17 and No. 21. So, for example strength at a rupture of a sample No. 16 makes 2,7-3,0 MPa, relative lengthening - 210-374%. The composition No. 21 on the basis of synthetic rubbers is optimum: SKD, SKN-26 including dye-kubozol blue ''K'' and the vulcanizing agent sulfur.

Physico-mechanical properties of this structure (No. 21 composition) following:

- strength at a gap, MPA 2,9

- relative lengthening of %, 452

- hardness across Shoru A 57-66

- elasticity on a rebound 28-42

This composition No. 21 has optimum physico-mechanical parameters for racetracks and can be recommended as sports coverings [8].

Thus, on the basis of the conducted researches an opportunity of regulation of necessary physico-mechanical properties for the purpose of receiving optimum composite materials which can be used as sports coverings is had: racetracks, tennis courts, volleyball and basketball courts.

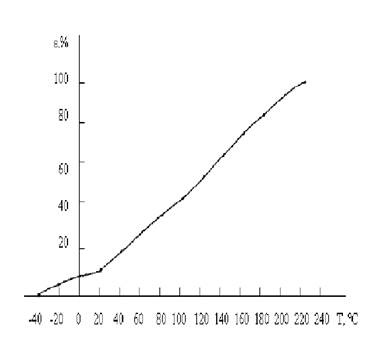

The thermomechanical curve of decomposition of glue mastic No. 30 for gluing of an armogidrobutil is given in drawing.

Apparently from drawing, the softening of composition begins at - 40 °C after +20 °C collapse on rectilinear dependence on loading. 100% loss of durability are reached at + 22 °C.

The area of highly elastic deformation is absent. Apparently, it is connected with presence of epoxy as binding, and butyl rubber plays an additive role.

CONCLUSIONS

1. The possibility of receiving glue mastics on the basis of butyl rubber and ED-20 epoxy with various additives is shown: kaolin and clays of various fields of Kazakhstan.

2. It is found that when replacing a kaolin by yellow and green clays the possibility of development of glue mastics with high values of tensile strength and relative lengthening is also caused.

3. The modifying influence of polymeric binding is established: epoxy and siloksane rubber on natural Kira (bitumeneconsist breeds), the glue mastics increasing durability.

4. The possibility of receiving glue mastics and sports coverings is shown.

Drawing - the thermomechanical curve of decomposition of the glue mastic No. 30 for gluing of an armogidrobutil including 10% - the BQ solution in Galosh gasoline, a kaolin, ED-20 and PEPA.

2. Abdikarimov M.N., Zhubanov B.A., Kusainova A.Sh., Nikonov V.S., Turgumbayeva R.Kh., Turarbayev K.T. Technology of receiving roofing materials on the basis of synthetic rubbers with fillers - clays of various fields of Kazakhstan. Interuniversity collection of scientific works "Problems of Technology and Economy of Construction Materials", Kaz GASA, Almaty, 1999. – P. 107-117.

3. Abdikarimov M.N., Vyshtayev I.I. In sb. "Rational use of industrial wastes in the region", Karaganda, 1989. – P. 89-90.

4. Abdikarimov M.N., Abdykadyrova Z.D., Kusainova A.Sh. In sb. "Rational use of production with application of environmentally clearly technologies in textile and tanning and shoe branches of light industry. Jambyl, on June 4-6, 1990. – P. 69-70.

5. Abdikarimov M.N., Zhubanov B.A., Baybolov S.M., Turgumbayeva R.Kh., Sabyrbayeva Sh.A., Sadchikov I.Ya. Processes of pyrolysis and development of polymeric composite materials as sports coverings - the Interuniversity collection of scientific works "Problems of Technology and Economy of Construction Materials", Kaz GASA, Almaty, 1999. – P. 89-100.

6. Abdikarimov M. N. Monolithic coverings on the basis of modified rubber - epoxy connections for plane sports constructions//Works of the III International scientific and practical conf. "Natural humanities and their role in implementation of the program of industrial and innovative development of the Republic of Kazakhstan". - Almaty, 2007. – P. 121-123.

7. Nadirov N.K. Oil and gas of Kazakhstan. Almaty, 1995. P. 2. - 400 p.

8. Baybolov S.M. Special materials for sports construction. Alma-Ata: Kazakhstan, 1980. - 128 p.

Abdikarimov M.N., Turgumbaeva R.Kh. PHYSICAL AND MECHANICAL PROPERTIES OF POLYMER COMPOSITE MATERIALS, INCLUDING PRODUCTION WASTES. International Journal Of Applied And Fundamental Research. – 2016. – № 4 –

URL: www.science-sd.com/466-25027 (11.02.2026).

PDF

PDF