About Us

Executive Editor:Publishing house "Academy of Natural History"

Editorial Board:

Asgarov S. (Azerbaijan), Alakbarov M. (Azerbaijan), Aliev Z. (Azerbaijan), Babayev N. (Uzbekistan), Chiladze G. (Georgia), Datskovsky I. (Israel), Garbuz I. (Moldova), Gleizer S. (Germany), Ershina A. (Kazakhstan), Kobzev D. (Switzerland), Kohl O. (Germany), Ktshanyan M. (Armenia), Lande D. (Ukraine), Ledvanov M. (Russia), Makats V. (Ukraine), Miletic L. (Serbia), Moskovkin V. (Ukraine), Murzagaliyeva A. (Kazakhstan), Novikov A. (Ukraine), Rahimov R. (Uzbekistan), Romanchuk A. (Ukraine), Shamshiev B. (Kyrgyzstan), Usheva M. (Bulgaria), Vasileva M. (Bulgar).

Engineering

Figure 1 - Rust and adhered soil

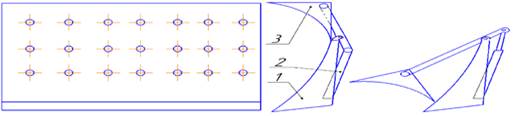

When working in soil conditions, appliances, namely working body interacts with the sticky soil (Figure 1). This phenomenon significantly reduces the reliability and performance [4]. The main part of the article is worth noting that the search for devices based on the earth-moving machine - the bulldozer, but the same methods can apply perfectly to other road building and transport engineering [5]. To solve this problem, inventors' certificates have been found (Figure 2).

.

1 – blade; 2 – cylinder; 3 – scraper.

Figure 2 - Blade with holes and depleted scraper

The first method - a blade with outlet openings for the liquid supply [1]. When included burial dump pump and a compressor, the feed liquid that flows through the outlet openings providing a sliding effect and reduced ground adhesion. The advantages include the diversity and speed of the liquid medium, which affects the efficiency of not sticking due to the selection of a specific chemical composition of the fluid to the desired category soil. The disadvantage of this method is the complexity of the design and manufacturing, as well the reliability and the need for additional hydraulic system. The second - a mechanical scraper [2]. Scraper from the upper position shifts lower and cuts the adhering soil. The disadvantages include a significant increase in the weight of the work equipment and installation of power equipment for cleaning.

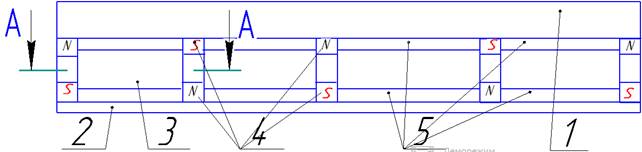

Due to fundamental science - physics, there is another way. This panel of opposite magnets [3]. The panel is between the frontal shield and a knife (Figure 3).

1 – blade; 2 – knife; 3 – panel; 4 – magnets; 5 - baffle

Figure 3 - Magnetic panel

When working with the ground with a knife cut a ground passes through the panel at this point on the ground affects the magnetic field generated by permanent magnets. As a result, the soil particles will be optional, anti-direction of the magnetic induction, magnetic moment arising due to the emergence of an additional current in an electron, because the particle is considered as a material point. In turn, the extra current arising due to precession (additional movement or rotation) generates one additional magnetic moment. When moving to the frontal shield the soil interacts with reduced tack, less connected due to the small adhesion forces between the particles, which is manifested in the form of lower sticking of soil and is better to go to the board surface. This increases the performance, reliability, performance and service life.

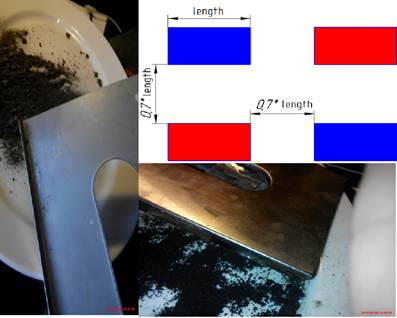

The study was carried out to find the optimal distance between the magnets in view of the fact that the ground in a heap will be taken as a material point particle, atom (cobalt, 59.93). The object of experience took loam moist soil category - 2. The metal plane has been used as the surface of the moldboard. On the plane, in a random position, installed magnetic elements with a certain distance. The total number of experimental tests for each distance - 40 pieces, except for the fifth position. There were five such provisions. First position – position without magnets. Second position - this position is close to the targeted one another eponymous poles. Third position - this is the position of the proximity of opposite magnets. Fourth position - the position of the large distance between the permanent magnets.

Figure 4 - The result of the optimal arrangement of magnets

The fifth position - a position of the optimal arrangement of the magnets (Figure 4).

Dm=![]() (22х5х9) (1)

(22х5х9) (1)

If the magnet will have a length, a width and a height of 22, 5 and 9 mm, respectively, the distance between magnets should be approximately Dm seventh of the length of the magnet. To bring real effect, also produces action "digging of soil". In this study, it showed positive result again. Thus, these studies have shown the effectiveness of magnets in the correct placement of the panel. And in general, it proved eksperemintalnym way, the theory of the precession of the magnetic moments in a magnetic field. Such an arrangement is appropriate and effective in the field of cleaning.

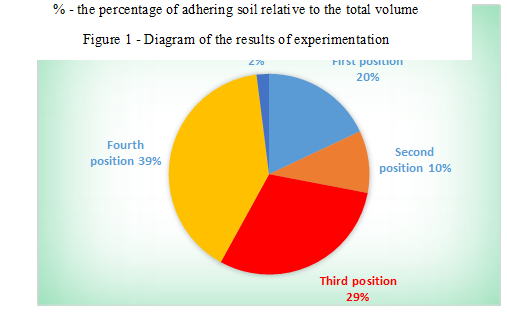

As a result of charting studies (Figure 5).

Conclusions: Under the conditions of the manufacturing process when dealing with cohesive soils dozer equipment, does not always meet the requirements of reliability, so the paper presents the development of the devices. The scientific and technical review of the methods of cleansing the surface of the moldboard is presented in the article. It outlines the main disadvantages of these methods. As it has been chosen and argued selection of the most optimal and efficient device. The following problems have been resolved to achieve the purpose of the article:

- patent search performed scientific inventions to solve problems;

- to calculate the main stress in the dangerous sections of the working equipment, taking into account the introduction of the device in order to reduce the adhesion of soil to the dump;

- explanations of the theoretical influence of the magnetic properties of the ground and the possible outcomes;

- calculated the effect of magnets and external magnetic fields on the elementary particles;

- implemented a scientific experiment on the article topics, thus proved the calculation and the theory of the object.

The big drawback is the complexity of the correct installation of the device in the equipment, taking into account the dimension of the power characteristics of the magnetic field.

The purpose and relevance of the topic are proved. It is therefore necessary to continue the study of this device and method for installing an operating bulldozer equipment, as well as pay attention to the electromagnets, to explore the impact and draw the necessary conclusions.

2. Copyright certificate the USSR № 141497 [electronic resource] – Access mode: http://patents.su/

3. Copyright certificate the USSR № 1518458 [electronic resource] – Access mode: http://patents.su/

4. Earth-moving working: Arinchenkov VI, Karpov VV, Garbuzov ZE, Batul AI, Don VM - M .: Higher School, 1982. - 335 p;

5. Earth-moving working: a textbook for university students in the specialty "Hoisting, building, road machines and equipment" / DP Volkov, V. J. Barker, PE Totlin etc .; under the total. Ed. DP Volkova. - M .: Engineering, 1992. - 448 pp, ill..

Maschenko V.N. DEVELOPMENT OF THE DEVICE TO IMPROVE THE RELIABILITY AND PRODUCTIVITY OF TRANSPORT AND ROAD-BUILDING MACHINES. International Journal Of Applied And Fundamental Research. – 2016. – № 5 –

URL: www.science-sd.com/467-25053 (28.02.2026).

PDF

PDF