About Us

Executive Editor:Publishing house "Academy of Natural History"

Editorial Board:

Asgarov S. (Azerbaijan), Alakbarov M. (Azerbaijan), Aliev Z. (Azerbaijan), Babayev N. (Uzbekistan), Chiladze G. (Georgia), Datskovsky I. (Israel), Garbuz I. (Moldova), Gleizer S. (Germany), Ershina A. (Kazakhstan), Kobzev D. (Switzerland), Kohl O. (Germany), Ktshanyan M. (Armenia), Lande D. (Ukraine), Ledvanov M. (Russia), Makats V. (Ukraine), Miletic L. (Serbia), Moskovkin V. (Ukraine), Murzagaliyeva A. (Kazakhstan), Novikov A. (Ukraine), Rahimov R. (Uzbekistan), Romanchuk A. (Ukraine), Shamshiev B. (Kyrgyzstan), Usheva M. (Bulgaria), Vasileva M. (Bulgar).

Engineering

ABSTRACT

The article reveals the theoretical and scientific-methodological basis of appliaction of the drilling fluids in view of reservoir properties of the rocks in situations of the abnormally high formation pressure.

This line of research is very relevant for countries with a complex structure of oil-producing and gas-bearing rocks, with the frequently replaced structure of the layered structure of the oil and gas strata.

This study can also be interesting in the design of oil and gas structures with complex geological and technical characteristics.

KEYWORDS: Drilling fluids, abnormally high formation pressure, complex geological and technical characteristics, composition of drilling mud, oil and gas fields.I. Introduction. Formulation of the problem

Drilling Fluid.

As is known from the theoretical literature (eng. drilling fluid, drilling mud; ger. Spülung, Bohrschlamm, Spülflüssigkeit) - complex multicomponent system dispersed suspension, emulsion and aerated liquids used for cleaning the wells during drilling. The use of drilling fluids for drilling first proposed in 1833 by the French engineer Flovil who has being watched cable drilling operation in which the drilling unit came across the water, noticed that the gushing water is very effective in removing cuttings from the well. He invented apparatus, which was supposed to pump water at the drill rod, where the drill cuttings are washed out with water to the surface between the drill rod and the wellbore. The principle has remained unchanged ever since.

Function

The main functions of a drilling mud can be summarized as follows:

- Remove cuttings from well

- Suspend and release cuttings

- Control formation pressures

- Seal permeable formations

- Maintain wellbore stability

- Minimizing formation damage

- Cool, lubricate, and support the bit and drilling assembly

- Transmit hydraulic energy to tools and bit

- Ensure adequate formation evaluation

- Control corrosion (in acceptable level)

- Facilitate cementing and completion

- Minimize impact on environment

Composition of drilling mud

Water-based drilling mud most commonly consists of bentonite clay (gel) with additives such as barium sulfate (barite), calcium carbonate (chalk) or hematite. Various thickeners are used to influence the viscosity of the fluid, e.g. xanthan gum, guar gum, glycol, carboxymethylcellulose, polyanionic cellulose (PAC), or starch. In turn, deflocculants are used to reduce viscosity of clay-based muds; anionic polyelectrolytes (e.g. acrylates, polyphosphates, lignosulfonates (Lig) or tannic acid derivates such as Quebracho) are frequently used. Red mud was the name for a Quebracho-based mixture, named after the color of the red tannic acid salts; it was commonly used in 1940s to 1950s, then was made obsolete when lignosulfonates became available. Other components are added to provide various specific functional characteristics as listed above. Some other common additives include lubricants, shale inhibitors and fluid loss additives (to control loss of drilling fluids into permeable formations). A weighting agent such as barite is added to increase the overall density of the drilling fluid so that sufficient bottom hole pressure can be maintained thereby preventing an unwanted (and often dangerous) influx of formation fluids.

Properties of drilling fluids and its regulation

Efficiency of application of the drilling fluids depends on its properties, which include the density, viscosity, fluid loss, gel strength, structural homogeneity, gas content, sand content; thixotropic, the content of ions of Na, K, Mg.

The fluid loss of the drilling mud is characterized by mud filtrate volume of (2 to 10 cm³) separated from the mud through a filter surface (filter press) with a standard pressure differential ~ 120 PSI for 30 minutes. The thickness of the filter cake (filter cake) which is formed by determining the water loss varies in a range of 1-5 mm.

The solids content of the mud characterizes the concentration of clay (3-15%) and weighting agent (20-60%). To ensure that the drilling efficiency (depending on the specific geotechnical conditions) mud properties controlled by changing the content ratio of the dispersed phase and the dispersion medium and introducing it's to special materials and chemicals. To prevent the kick at abnormally high formation pressures its necessary increase the density of the drilling fluid through the introduction of special weighting agents (such as chalk up to 1500 kg / m³, barite and hematite up to 2500 kg / m or higher), or reduce it to 1000 kg / m³ by aeration mud or adding to it blowing agents (sulfanol, lignosulfonate). The solids content of the drilling fluid system is regulated by three-stage cleaning system on shale shakers; gaseous agents separated in degassers. In addition, for adjusting the solids content of the solution adding selective flocculants.

A special class of reagents are using for controlling the properties of oil-based solutions. They include emulsifiers (fatty acid soaps, and other emultal...), repellents (sulfanol, quaternary amines and organosilicon compounds), filtration reducer (organogumaty).

The mixing / preparing of the drilling fluids are performing prior starting drilling and while drilling process.

The raw material composition of drilling fluids

For prepare/mix drilling fluids are used fine, plastic clay with a minimum content of sand which can form a viscous, long settled suspension with water. The best properties have a significant alkaline (sodium) varieties montmorillonite (bentonite clays), clay powders, which are mainly used in drilling oil and gas wells and for the preparation of drilling fluids with low density.

The harmful impurities in the clays, deteriorates the stability of the mud are gypsum, soluble salt, limestone.

According to the specifications (TU U 39-688-81 [1]), the main indicator of the quality of raw clay and clay powder intended for the preparation of drilling fluids is to reach a solution - the number of cubic meters of solution (suspension) of a given viscosity, obtained from 1 ton of raw clay. In addition are regulated by the density of the solution and sand content.

Circulation of drilling fluids in the hole

Most drilling fluids in drilling operations are recycling to the following cycle:

- Drilling fluids are mixed and kept in special tanks

- Mud pumps pump the drilling fluid from the tanks into the wellbore through drill string

- Drilling fluid reach to the bottom through drill string where the drill bit break the formation

- Then, drilling fluid returns to the surface, carrying out drill cuttings, which were separated chisel.

The drilling fluid moves through annulus - the space between the walls of the hole and the drill pipe. The typical diameter of the drill pipe about 12.7 sm. The bottom of the deep hole, its diameter may be about 20 sm.

At the surface the drilling fluid passes through the return line - a pipe that leads to a vibrating sieve (shale shaker).

The sieve consists of a series of vibrating grids of metal, which are used for separating cuttings from the fluid. The fluid flows through the grate and back to the sump.

The particles of the cuttings fall into the trough for remove. Before release, they can be purified starting from environmental and other considerations. Some of the cuttings are taken by geologists to study the condition of the wellbore.

Variety of drilling fluids

Lignite alkaline drilling fluid - drilling mud into which adding a certain amount of lignite with alkaline in nature.

Lime-bitumen drilling fluid - oil-based mud dispersion medium which is a diesel fuel or oil, and the dispersed phase - highly oxidized bitumen, calcium oxide, barite, and a small amount of water required for slaking.

Lightened drilling fluid - drilling fluid, reduced in weight, light, which has a lower density. Thus is used for drilling and well killing in formations with low formation pressure.

Polymer drilling fluid - water based mud which has high molecular polymers of the linear structure; usually used for drilling hard rock [1-5].

1. Abnormal reservoir pressure

From the same theoretical scientific sources it becomes clear that the abnormal reservoir pressure (eng. Abnormal seam pressure; ger. Anomaler Flozdruck; french. Pression anomale des souches; spain. Presion anomal en capas) - the pressure acting on the fluids (water, oil, gas) contained in the pore space of rocks which value is different from the normal (hydrostatic).

Reservoir pressures in excess of hydrostatic, it means that the column pressure of the fresh water (density 103 kg / m3), the height equal to the depth of the formation at the measuring point, called the abnormally high (AHRP) is less than the hydrostatic - abnormally low (ALRP).

Abnormally reservoir pressure exists in isolated systems. On the genesis of the anomalous reservoir pressure is no consensus. The main causes of abnormally reservoir pressure are considered the seal of clay rocks, the processes of osmosis, catagenetic transformation of the rocks and they contain organic matter, and the processes of tectogenesis and geothermal conditions of the subsurface. Each of these factors may predominate, depending on the geological structure and history of the region. However, according to some researchers, major, apparently, is the temperature factor, since the coefficient of thermal expansion of various fluids, enclosed in an isolated volume of rocks is much greater than the mineral components of the rocks.

Abnormal reservoir pressure mounted by drilling multiple wells on land and waters in the search, exploration and development of oil and gas deposits in the sediments from the Pleistocene to the Precambrian in a wide range of depths. More common AHRP, they are especially widespread at great depths (over 4 km). Usually AHRP exceed the hydrostatic pressure in the 1.3-1.8 times, much less in 2.0-2.2; thus they do not usually reach values of geostatic pressures exerted overburden weight. However, in a few cases at great depths were recorded AHRP equals or exceeds the value of geostatic pressure, which, apparently, due to the influence of other factors (f.e. as a result of manifestation of earthquakes, mud volcanism, growth hydrochloric dome structures). AHRP found in the Russian Federation in the Volga-Urals, the South Caspian, Dnieper-Donetsk, Western Siberia, the Afghan-Tajik, North Prev Carpathian and other oil and gas basins; abroad - in the basins of the Persian Gulf and the Gulf of Mexico, Sahara-Eastern Mediterranean, Central European, and others. ALRP can be artificially induced in oil, gas and water, if there is no replenishment taken from the reservoir fluids. Surface features such pressure reduction - surface subsidence. ALRP recorded in USSR in North Prev Carpathian, Dnieper-Donetsk, North Black Sea, Irkutsk and other oil and gas basins, known abroad in the San Juan Basin, Prev Appalachian, Denver and others.

Availability AHRP beneficial effect on reservoir properties of host rocks and increases the natural operation of oil and gas fields without the use of expensive secondary methods, increases the specific gas reserves and production per well is favorable to the preservation of hydrocarbon accumulations, indicates the presence of oil and gas basins in isolated areas and zones . The zones of AHRP developed at greater depths, especially where they are regional distribution, contain considerable resources of methane, which is in the dissolved state in the superheated (up to 150-200 ° C) water. Methane can be recovered and also use hydraulic and heat energy of the water. On the other hand, the AHRP are a source of accidents during drilling. The unexpected opening of the AHRP zones - the cause of many complications, the elimination of which leads to high material costs. When drilling in areas of AHRP the drilling fluid is increased to prevent ejections from the wells. But such a fluid can absorb layers with hydrostatic pressure and ALRP. Therefore, prior opening the overlying rocks with AHRP the overlying absorbing layers are overlapped with casing. If the pressure distribution in the rocks at depth is known, it is possible to choose the optimal design of the well, technology of the drilling and cementing and to prevent possible complications and failures. The availability of zones of the AHRP significantly increases the cost of wells. To predict AHRP are used mainly seismic exploration, drilling data, and various types of log (electrical, acoustic, gamma ray, neutron, and others).

Given all of the above it is evident that, system design calculations of the characteristics of the geological section, requiring the analysis of objectively existing, identified in practice, qualitative and quantitative relationships between the different characteristics that affect the process of drilling, survey and identify relationships between geological, geophysical, mechanical and technological characteristics of the layer. Study of lithological-capacitive characteristics of the rocks of the geological layer is one of the most important tasks of the exploration drilling, the solution of which allows timely to develop and adjust the program to build the wells. Usually while assessing lithological-capacitive properties and lithological breakdown of the layer uses the results of analysis of the cutting, as well as the interpretation of the GIS. However, in cutting metrical studies the accuracy of the quantitative estimates depends on the conditions of transport of the cuttings in the wellbore, the intensity of moving, as well as a number of subjective factors. The use of GIS to study the lithological features of the layer allows you to more accurately produce the dismemberment of the rocks. But this information cannot be obtained during drilling. More efficient for purposes of the operational lithological breakdown of the rock during drilling is a method based on the analysis of the rate of penetration (ROP) as an indicator of the strength of unsealed deposits, and forms the basis of the geological-technological researches (GTR). Strength properties of the rocks, in turn, depend on the lithology, structural and textural features, as well as the magnitude of the resultant vector of the stress created on the bottom of the well. Ceteris paribus, the value of the critical stress (tensile strength of rocks) is directly proportional to the strength of coupling between the individual particles of the rock and magnitude of the differential pressure at the bottom of the well. Thus, the rate of penetration increases with increasing the graininess and a breakdown in communication between the individual components of the rock under the influence of pore pressure or while a weak cementation of sediments. Drilling data also allow us to promptly assess pore pressure both qualitatively and quantitatively, which is very important when making decisions while drilling. The efficiency of the forecast estimates increases with the integrated use of technology as well as geological and geophysical information.

As the analysis of the literature devoted to assess the performance of the well sections, as well as patterns of change in the rate of penetration with depth, the presence of such relationships allows more deeply explore the geological section, assess the geological characteristics that were not previously evaluated, as well as improve the accuracy of the previously estimated characteristics.

Therefore, to assess the geological characteristics of the rocks that form the incision of the filed (lithology, filtration-capacitive parameters, mechanical properties, as well as baric formation characteristics of the formation), in various studies used data that were subjected to statistical analysis.

The analysis of the research, as well as drilling results show that the actual levels of the characteristics of the process fluctuate and are random, which is used in the methods and systems are not taken into account. Therefore, the obtaining accurate estimations of characteristics of the geological section substantially impeded. On the other hand, as noted in a number of papers, in particular, this circumstance brings substantial difficulties in some cases while establishing the position of the line of the normal seal of the clays from drilling and related definitions transition intervals to the zones of the increased pressure. In such cases, the data smoothing is usually performed. The essence of the various methods by which the smoothing is the replacement of the actual levels of a number of settlement having a significantly lower volatility than the original data.

In actual use of the results of the drilling the wells is necessary to obtain some, having a place in this case regularity, even in the case of pother in them. Therefore there is a need to study some random processes compared to other (pulsed interference). This fact was taken into account by the authors in the preparation of the program that has been used by us during the calculations. In this case, while processing was used the method of automatic selection.

Changing statistics of the automatic selection allows you to judge whether the considered system is homogeneous, i.e. you can define uniform intervals by its value calculated for the index of the drilling.

Comparison of mechanical logging data with the data from other methods that reflect the lithology shows that the rate of penetration in sandstones is 3-5 or more times higher than the rate of drilling in clay rocks. In work it is shown that between the index of lithology, which is adopted as a relative parameter aпс and mechanical speed there is a strong positive relationship: the higher the value of the aпс, the higher the mechanical speed.

To improve the drilling of the rocks with increasing parameter aпс also indicated in work.

A relationship between lithology and rock drilling capacity allows create lithological dismemberment of the section according to drilling data, as well as solve the inverse problem in the case of necessary prediction of the drilling regarding geological and geophysical information.

Thereby in some works based on a large amount of geological-geophysical and technological information obtained from drilling wells in Russia, Azerbaijan, Kazakhstan and others attempted to obtain dependencies between parameters representing specified information arrays.

According to drilling and well logging performed statistical analysis and built according to the difference of the parameter sigma logging, numerically equal to the ratio of points on the scope of the sigma-logging to a large value, and "drilling strength" (drilling index) regarding sigma logging on the parameter aпс on example of the section of the one of the field.

Marked dependences approximated as follows: the differential parameter of the sigma logging

Δσ=0,62αпс1,94 (1)

The index of the drilling regarding sigma logging

(2)

(2)

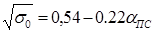

The analysis showed that the differential parameter is also closely associated with argillaceous rocks. From drawing 1, which shows this dependence, it is seen that with the increase of the differential parameter of the sigma logging the value of the argillaceous rocks decreases, obeying an exponential law:

С=78,6exp(-4,18Δσ) (3)

The presence of these relationships allows you to use the differential parameter of the sigma logging for solve various geological, geophysical and technological problems.

Relationship between the values of the differential parameter of the sigma logging and parameter aпс and clay content is the basis for assumptions about its possible connection with the continuity of the rocks, which was proposed in work as the characteristics necessary for a more complete accounting

Figure1. Dependence on clay from lithological characteristics of a set of indicators for the classification of rock properties of the section on drilling

Continuity, according to describes the whole range of violations of the surface of the rocks pore system, cavities and cracks, penetration enhancer mud into the rock. There are four categories of rocks on continuity: from highly fractured, porous, permeable rocks (I category) to dense, argillaceous rocks and anhydrite (IV category). Comparing the categories of continuity of the rocks with the values of the differential parameter shows, that in the range of the values Dsε [0; 0.11) are placed the rocks of the fourth category of the continuity at Dsε [0.11; 0.26) - third, but at Ds³0.26 - second and first.

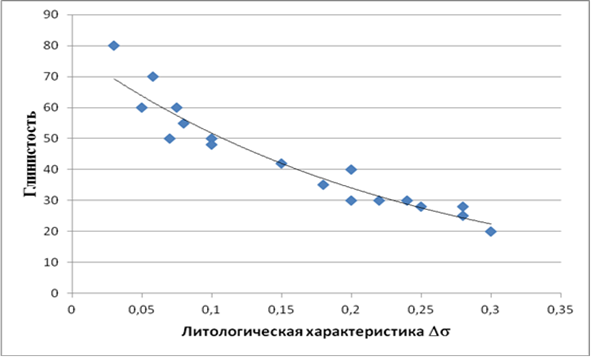

With this correlation it is possible to link the main evaluated characteristics of the geological section with the parameters determined from drilling wells. At the same time, the evaluation allowing carrying out quantitative calculations, carried out by expressing the results of the analysis using categories, the number of which captures a certain type of the rock. However, the analysis showed a close relationship between such characteristics as sand content and the double relative characteristic of the sigma logging, which is obtained by dividing the current values of the relative difference of the parameter of the sigma logging to its maximum value in the context of the well. This dependence is linear, and in change there are two characteristics of the considered dependence (Fig. 2): at the values of the dual relative parameter from 0.042 to 0.75 (Fig. 2,a):

П = 56,88 Ds` + 17,35; (4)

At Δσ` = 0,75... 1:

П = 59,31Δσ` - 26,85; (5)

Where П is the sand content, %; Δσ`- dual relative parameter of the sigma logging

Geological and technological information obtained during drilling of the wells, can be used not only to make a decision in the drilling process. The accumulation of such information may be used to generalization of the results of the drilling to classify geological section on drilling, as well as estimates of reservoir characteristics. Consequently, one of the most promising is to find relationships between geophysical and technological characteristics of the section that would allow some transformations to create the linking of these data with indicators assessed in the process of drilling a well.

Such communications are also necessary in order to while drilling enable to evaluate the characteristics identified by the well logging data, especially in those intervals section where they are not carried out or carried out in a limited volume.

Figure2. Dependence of the sand content of the rocks from double relative parameter of the sigma logging: a) at values

Δσ`=0,05...0,75; b) at values Δσ` =0,75...1

In other words, the presence of these relationships allows according drilling data to have an idea about the lithology, receive information on clay and sand content and other characteristics of the geological section, required to deal with both geological and technological challenges. This is very important, especially in the conduct of drilling operations in areas where according the section of the drilled well there is no information or there is a limited extent.

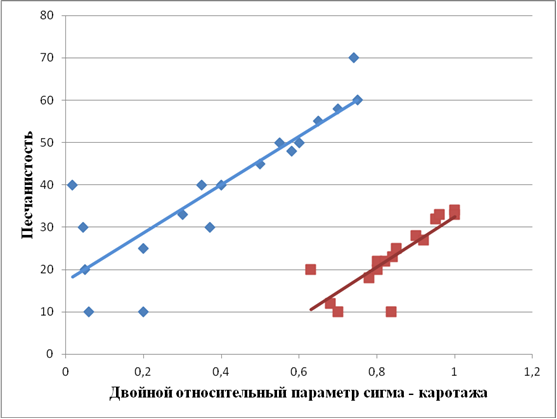

Change of the sand content with the depth on the example of one of the wells is shown in figure 3.

Figure 3. The change of percentage of clays, sandstones, siltstones, and others rocks with depth

Sandstones; Clay; Siltstone, other rocks;

According to the complex geological and technological research in the process of the drilling one of the fields received lithological and filtration-capacitive characteristics, presented in Figure 4.

Numerous observations indicate that during drilling in normal conditions and constant values of relative mode parameters the rate of penetration decreases with the depth. This is due to the increase in density with depth (and related hardness) of rocks. However, in the transition zones and zones of elevated reservoir (pore) pressure the penetration rate increases. The present circumstance the researchers explain the pore sealing of the rocks, leading to an increase in their porosity, thereby reducing the hardness, and they are drilled with a relatively high speed. At the same time, while drilling as is known the differential pressure influence on the mechanical speed, i.e. the difference between the hydrostatic pressure of the mud column and the reservoir pressure. Reducing this pressure is also a reason for the increase of mechanical speed [6-10].

These regularities formed the basis for allocation of zones of abnormally high reservoir (pore) pressure on ROP. On their basis, created and in recent years improved the various methods composing the main part of the geological and technological research in the drilling process.

Thus, comprehensive information about the drilling allows you to get the regularities necessary for the study of the geological section in the drilling process.

Results of the GTR allow reliably identify the zones of the higher pressures zone in real time, now .

As noted in work, the results of the GTR agreed with measurements of reservoir pressure and well behavior during their carrying out in Western Siberia.

Geophysical and petro physical characteristics of the Upper Jurassic deposits of the Western Siberia complicate the application of traditional approaches for assessing pore pressures as per GTR, in spite of a fairly complete set of these researches.

In work it is noted that the complex of developed programs allows rapid assessment of pressure on mechanical logging, core parameters, cuttings and GTR data. Also, there are made an adjustment density and well design.

"The integrated methodological approach" according to, developed in "Kubangazgeofizik" allows to estimate pore pressures, build and refine the line of the normal seal (plugging), evaluate stability of the borehole and the recommended density of the drilling fluid and through any specified period of time to assess the degree of plasticity of clays and the category of hazard of collapse of the casing.

In general, many works in this direction show ever increasing interest of researchers to this sphere, which is currently one of the main stages of the drilling of wells, provided by leading companies.

As per review of the various researches, the most accurate estimate of the characteristics of the geological sections on technological data of the drilling is possible with a deep analysis of data and identification of the different models that form the basis of relevant programs, to the really considered conditions [6-12].

III. Results

As a result of development of the research abstract, you can draw the conclusions as per below:

In general, numerous works towards the development of the scientific foundations of reservoir properties of the rocks located in abnormally high pressure show ever increasing interest of researchers in this sphere, which is at present one of the major in drilling of oil and gas wells.

As per review of the various researches, the most accurate estimate of the characteristics of geological sections on technological drilling data available:

1. With deep analysis of information and the identification of the different models that form the basis of relevant programs, to really considered conditions;

2. With deep research of parameters of the sigma logging and their connection with the lithological characteristics of the section;

3. In the need to identify dependencies, allowing as per process data to assess lithology in the drilling process;

4. In the need to use the scheme of calculations and methods for determining the pore pressures.

Mahmudov T.A. DEVELOPMENT OF SCIENTIFIC BASIS OF APPLIACTION OF THE DRILLING FLUIDS IN VIEW OF RESERVOIR PROPERTIES OF THE ROCKS IN SITUATIONS OF THE ABNORMALLY HIGH FORMATION PRESSURE. International Journal Of Applied And Fundamental Research. – 2017. – № 2 –

URL: www.science-sd.com/470-25214 (11.02.2026).

PDF

PDF