About Us

Executive Editor:Publishing house "Academy of Natural History"

Editorial Board:

Asgarov S. (Azerbaijan), Alakbarov M. (Azerbaijan), Aliev Z. (Azerbaijan), Babayev N. (Uzbekistan), Chiladze G. (Georgia), Datskovsky I. (Israel), Garbuz I. (Moldova), Gleizer S. (Germany), Ershina A. (Kazakhstan), Kobzev D. (Switzerland), Kohl O. (Germany), Ktshanyan M. (Armenia), Lande D. (Ukraine), Ledvanov M. (Russia), Makats V. (Ukraine), Miletic L. (Serbia), Moskovkin V. (Ukraine), Murzagaliyeva A. (Kazakhstan), Novikov A. (Ukraine), Rahimov R. (Uzbekistan), Romanchuk A. (Ukraine), Shamshiev B. (Kyrgyzstan), Usheva M. (Bulgaria), Vasileva M. (Bulgar).

Engineering

It is known that the cutting edge machining of workpieces with a hardness of 40...50 HRC the most difficult. Cutting ceramics in the processing of such workpieces quickly wear out. The reason is that due to insufficient hardness of the material on the front surface of the tool formed by the build-up that causes chipping of the cutting edge at the breakdown.

To prove this hypothesis, an experiment was conducted with the objective to compare resistance of the plate of wok-60 with different hardness of quenched workpieces made of steel 45 and to determine its mechanism of wear.

Processing was carried out on a lathe 16К20Ф3С32. For the experiment, two billets of cylindrical shapes were hardened to a hardness of 45 HRC and 54 HRC.

The nature of the wear and the structure of the plates was studied with the HITACHI S3400N electron microscope, which was able to perform micro-X-ray spectral analysis.

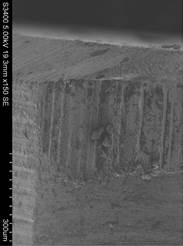

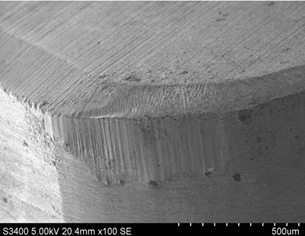

It is established that the plates in the experiments wear out mainly along the rear surface. The wear had the character of notch. .

a)

a)

b)

b)

Fig. 1. The microstructure of the plates VOC 60, worn on a back surface when machining hardened steel 45: a) - HRC45, b) - HRC54

From the photos you can see that the number and volume of growth on the back surface of the wafers processed workpiece hardness HRC 45 is much larger than on the rear surface of the plate, producing processing of the workpiece with a hardness of HRC 54. The results of x-ray analysis show that the present growth of the oxides FeO, Fe2О3 is, as well as connections FeAl2О4, FeSiО4. The etching outgrowth revealed that at the sites of wear are cracks with signs of microscrew. Microanalysis of the worn pad has allowed to establish that build-up causes the formation of pores, which is then distributed into and concentrate in the form of microcracks, which subsequently leads to microscale. The formation of microcracks at the grain boundaries due to the pore formation and creep them into plates under the influence of vibration of the tool leads to chipping of the cutting edge.

2. Pronin A.I., Mylnikov V.V., Chernyshоv E.A. Causes of poor working capacity of plates from cutting ceramics at hard turning // Materials Science. 2014. No. 5. Р. 13-15.

3. Pronin A.I., Mylnikov V.V., Shchelkunov E.B., Vinogradov S.V. Application of orthogonal central compositional planning of experiments to optimize the turning of hardened steel 40X with cutting ceramics // Bulletin of Machine Building. 2016. No. 8. P. 43-48.

Pronin A.I., Mylnikov V.V., Shchelkunov E.B., Kondrashkin O.B., Chernyshov E.A., Valko D.A., Vinogradov S.V. THE CHARACTER OF WEARING AND STRUCTURE OF PLATES FROM CUTTING CERAMICS AT TURNING PROCESSING. International Journal Of Applied And Fundamental Research. – 2017. – № 3 –

URL: www.science-sd.com/471-25286 (11.02.2026).

PDF

PDF