About Us

Executive Editor:Publishing house "Academy of Natural History"

Editorial Board:

Asgarov S. (Azerbaijan), Alakbarov M. (Azerbaijan), Aliev Z. (Azerbaijan), Babayev N. (Uzbekistan), Chiladze G. (Georgia), Datskovsky I. (Israel), Garbuz I. (Moldova), Gleizer S. (Germany), Ershina A. (Kazakhstan), Kobzev D. (Switzerland), Kohl O. (Germany), Ktshanyan M. (Armenia), Lande D. (Ukraine), Ledvanov M. (Russia), Makats V. (Ukraine), Miletic L. (Serbia), Moskovkin V. (Ukraine), Murzagaliyeva A. (Kazakhstan), Novikov A. (Ukraine), Rahimov R. (Uzbekistan), Romanchuk A. (Ukraine), Shamshiev B. (Kyrgyzstan), Usheva M. (Bulgaria), Vasileva M. (Bulgar).

Engineering

In modern conditions of tough competition engineering enterprises seek to maximize the opportunities of computers in solving problems of design and production. To automate these tasks use CAD/CAM/CAE system.

The aim of this work is to produce a rapid analysis of the part "shell", which consists in assessing the strength of the developed design of allowable stresses, determine the most weaknesses design, the ability to make necessary changes (optimize) the product.

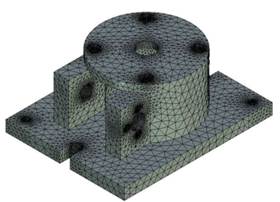

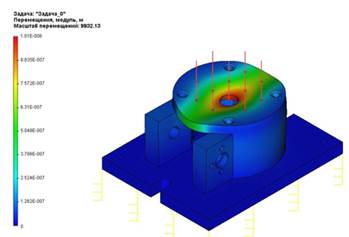

As object of research used 3D model of the part "body". For a rapid analysis of the details of the "case" was used T-FLEX Analysis is integrated with T-FLEX CAD environment finite element calculations. The module calculates the response of a structure under the action applied to the system of forces. The result of the work of the developer in the module is to obtain estimates of the strength of the designed structure of allowable stresses, determination of weak points of the design and change of design of the product i.e. its optimization.

а

а

b

b

Fig. 1. a) - tetrahedral finite element model of the product with generation of the grid of the 3-D model; b) - are the largest displacements

For strength calculation were specified boundary conditions. The function of the boundary conditions in the static, perform fastening and is attached to the system impact forces. Created by a force evenly distributed on these faces of the part. Force is directed perpendicular to the loading faces of the part.

From figure 1,a,it is seen that the largest module move will have the edges of the upper part of the body, and the maximum equivalent stresses occur in the hole located in the center of the upper part of the product. Were the numerical values of displacements and stresses, allowing you to change the dimensions of the body, achieving the required strength and stiffness of the part. In this case, after the choice of the safety factor for equivalent stresses determined that the margin of safety should be determined by the yield strength of the component material. From the analysis results it can be concluded that the case is not much loaded, and has a significant reserve. From this it follows that it is possible to perform optimization details to strengthen weak areas and reduce the weight of parts, by reducing the unloaded areas.

Valko D.А., Pronin A.I., Kondrashkin O.B., Mylnikov V.V. EVALUATION OF STRENGTH DETAILS WITH USING CAM / CAM / CAE SYSTEM. International Journal Of Applied And Fundamental Research. – 2017. – № 3 –

URL: www.science-sd.com/471-25289 (11.02.2026).

PDF

PDF