About Us

Executive Editor:Publishing house "Academy of Natural History"

Editorial Board:

Asgarov S. (Azerbaijan), Alakbarov M. (Azerbaijan), Aliev Z. (Azerbaijan), Babayev N. (Uzbekistan), Chiladze G. (Georgia), Datskovsky I. (Israel), Garbuz I. (Moldova), Gleizer S. (Germany), Ershina A. (Kazakhstan), Kobzev D. (Switzerland), Kohl O. (Germany), Ktshanyan M. (Armenia), Lande D. (Ukraine), Ledvanov M. (Russia), Makats V. (Ukraine), Miletic L. (Serbia), Moskovkin V. (Ukraine), Murzagaliyeva A. (Kazakhstan), Novikov A. (Ukraine), Rahimov R. (Uzbekistan), Romanchuk A. (Ukraine), Shamshiev B. (Kyrgyzstan), Usheva M. (Bulgaria), Vasileva M. (Bulgar).

Phisics and Mathematics

A problematic feature of any hardening heat treatment is the warping of parts, exceeding the allowance for subsequent processing in the size of the mating surfaces by grinding. Among the many reasons causing buckling, the chemical heterogeneity or segregation along the cross section of the part that is essential for the diffusion saturation of the surface layer with adsorbate is essential [1-3].

The purpose of the work is to determine the internal stresses arising during hardening of heavily loaded parts of machines with a variable chemical composition over the cross section during the heat treatment.

The algorithm for solving the elastoplastic problem for finding the thermally stressed state of a steel cylinder with a constant chemical composition was proposed by Timofeev VN, Samoilovich Yu.A. [4].

Using this algorithm, a technique for calculating internal stresses is proposed, when the chemical composition across the section is variable. In calculating internal stresses, a cylinder of steel 12ХН3А with a diameter of 56 mm was used, which was subjected to chemical-thermal treatment. Thermophysical characteristics of specific layers of the product with different chemical composition were taken into account:

- heat transfer coefficient α;

- coefficient of thermal conductivity λ;

- coefficient of thermal diffusivity a;

- coefficient of linear expansion of β.

Calculation of internal stresses during cylinder heating and cooling was performed in the MathCad program. In the computer program for calculating thermal stresses during heating and cooling of parts, the main thermophysical properties of steels were introduced, taking into account their layer-by-layer variation along the cross-section.

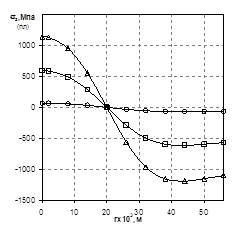

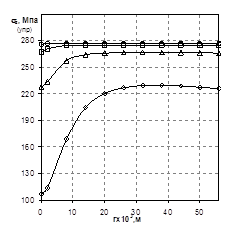

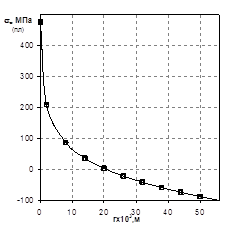

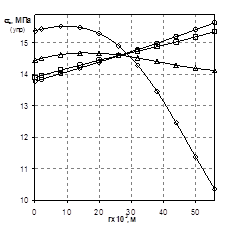

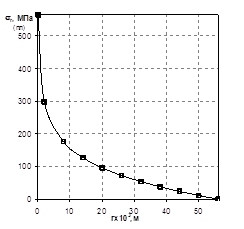

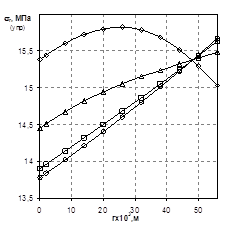

Based on the calculation results, the dependences of the main elastic and plastic stresses are constructed during heating and cooling of a steel cylinder. Figure 1 shows the distribution of elastic and plastic stresses σупр and σпл at a distance r from the center of the cylinder when cooled in oil:

a)

a) b)

b)

c)

c) d)

d)

e)

e) f)

f)

Fig. 1. Change in stresses s as a function of the distance to the surface of the cylinder r during quenching in oil: ο -7 min; □ -4 min; Δ-2 min; ◊-30 seconds. a - dependence of axial plastic stresses σzпл; b - dependence of axial elastic stresses σzупр; c - dependence of plastic tangential stress σtпл; d - dependence of elastic tangential stresses σtупр; e - dependence of plastic radial stresses σrпл; f - dependence of elastic radial stresses σzупр.

Analyzing the obtained results we find that some components of elastic and plastic stresses have extremely high values, which correspond to the current technological process of manufacturing the shaft-gear part from steel 12ХН3А consisting in the following: - cementation, t = 910°С, heating 1 hour, holding 13 hours , cooling in air to 20°C.

2. Zinchenko V. M. surface Engineering of gear wheels by methods of himiko-thermal processing. – Moscow: iz-vo MGTU im. N. Uh. Bauman, 2001. 303 p.

3. Rozhkov, I. I., Mylnikov V. V. Assessment of the sensitivity of steels to cracking in heat treatment processes // international journal of applied and fundamental research. 2013. No. 10 (part 2). Р. 244.

4. Timofeev V. N., Samoilovich Yu. a. estimation of the effect of plastic deformation on thermal stresses during heating of the steel cylinder // Combustion, heat transfer, heating processes: collection of scientific works vniimt. – Sverdlovsk: vniimt, 1963. No. 10. P. 68-80.

Mylnikov V.V., Rozhkov I.I., Pronin A.I., Kondrashkin O.B. CALCULATION OF THERMAL STRESSES DURING HEATING AND COOLING OF PARTS WITH REGARD TO THERMOPHYSICAL PROPERTIES. International Journal Of Applied And Fundamental Research. – 2017. – № 3 –

URL: www.science-sd.com/471-25293 (28.02.2026).

PDF

PDF