About Us

Executive Editor:Publishing house "Academy of Natural History"

Editorial Board:

Asgarov S. (Azerbaijan), Alakbarov M. (Azerbaijan), Aliev Z. (Azerbaijan), Babayev N. (Uzbekistan), Chiladze G. (Georgia), Datskovsky I. (Israel), Garbuz I. (Moldova), Gleizer S. (Germany), Ershina A. (Kazakhstan), Kobzev D. (Switzerland), Kohl O. (Germany), Ktshanyan M. (Armenia), Lande D. (Ukraine), Ledvanov M. (Russia), Makats V. (Ukraine), Miletic L. (Serbia), Moskovkin V. (Ukraine), Murzagaliyeva A. (Kazakhstan), Novikov A. (Ukraine), Rahimov R. (Uzbekistan), Romanchuk A. (Ukraine), Shamshiev B. (Kyrgyzstan), Usheva M. (Bulgaria), Vasileva M. (Bulgar).

Phisics and Mathematics

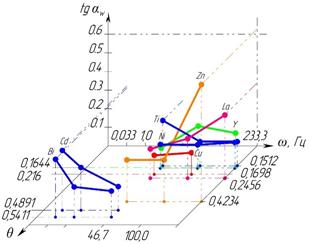

The study was subject to cylindrical samples with a diameter of 2 and 5 mm from metals with different crystal lattice type and the values of the homologous temperature (θ) on fatigue in a wide range of frequency of loading (ω) according to the scheme of the rotating bending specimen. Surface damage was assessed by changes in the microstructure of the material under the action of alternating stresses. As evaluation characteristics were the slip bands emerging at the thin section sample from the area of the greatest stresses [1]. Quantitative evaluation of fatigue resistance was the slope of the left branch of the curve to the axis of the loops (tg αw) [2-3].

The homological temperature is determined by the ratio:

Θ =  , (1),

, (1),

where Топ = tоп+273 оС, - the temperature of the experience, i.e. the temperature at which the experiment was conducted, К; Тпл = tпл+273 оС - the melting point of the metal, К.

Tests were carried out at room temperature, so according to (1) at the same temperature of the experiment, the homologous temperature of various metals would be significantly different.

With increasing frequency cycles (ω) increases with strain rate. Speed effect, under the condition ω2 > ω1, the stress σω2 is always greater than σω1 (except for cases related to deformation aging), is observed for all metals tested, but to different degrees [4]. The higher homologous test temperature (Θ), the stronger should be pronounced speed effect, i.e. change of frequency of cyclic loading is more significant impact on performance of fatigue resistance. With increasing temperature the density of bands of slip increases (speed is enhanced), i.e. the lateral slip increases. The slope of fatigue curves with increasing temperature is increasing. However, one should bear in mind that at the pre-melting temperature the effect of speed on the voltage may become weaker. In this case, the durability is determined by the creep, which involves, as you know, over time, not with the number of loading cycles.

Fig. 1. Communication of an index of resistance of a fatigue (tgαw) at change of frequency of cycles of a loading (ω) and homologous temperature (Θ)

Figure 1 shows the experimental results of the tested metals with different types of crystal lattice in the form of dependence of change of resistance of the fatigue slope of the left branch of the fatigue curve, frequency of loading cycles and homologous temperature. The comparison of values of the homologous temperature change resistance to fatigue and cyclic loading frequency gives the opportunity to characterize the effect of (Θ) is more or less predictable (tgαw) only in the region of values of about 0.5 in the low frequency range. In the field values below 0.4 are obviously ambiguous appearance (Θ) due to the competing physical processes within the material structure.

2. Mylnikov V.V., Shetulov D.I., Chernyshov E.A. Variation in faktors of fatigue resistance for som pure metals as a function of the freguensy of loading sycles // Russ. J. Non-Ferr. Met. 2010. Vol. 51. P. 237–242.

3. Shetulov D.I., Kravchenko V.N., Myl’nikov V.V. Predicting the Strength and Life of Auto Parts on the Basis of Fatigue Strength // Russian Engineering Research. 2015. Vol. 35. P. 580–583.

4. Mylnikov V.V., Shetulov D.I., Chernyshov E.A. Speed Effect upon Varying the Cyclic Loading Frequency for Certain Pure Metals // Russ. J. Non-Ferr. Met. 2015. Vol. 56. No. 6. P. 627–632.

Mylnikov V.V., Shetulov D.I., Pronin A.I., Kondrashkin O.B., Chernyshov E.A. THE INFLUENCE OF THE HOMOLOGOUS TEMPERATURE ON THE PARAMETERS OF FATIGUE RESISTANCE OF METALS. International Journal Of Applied And Fundamental Research. – 2017. – № 3 –

URL: www.science-sd.com/471-25295 (11.02.2026).

PDF

PDF