About Us

Executive Editor:Publishing house "Academy of Natural History"

Editorial Board:

Asgarov S. (Azerbaijan), Alakbarov M. (Azerbaijan), Aliev Z. (Azerbaijan), Babayev N. (Uzbekistan), Chiladze G. (Georgia), Datskovsky I. (Israel), Garbuz I. (Moldova), Gleizer S. (Germany), Ershina A. (Kazakhstan), Kobzev D. (Switzerland), Kohl O. (Germany), Ktshanyan M. (Armenia), Lande D. (Ukraine), Ledvanov M. (Russia), Makats V. (Ukraine), Miletic L. (Serbia), Moskovkin V. (Ukraine), Murzagaliyeva A. (Kazakhstan), Novikov A. (Ukraine), Rahimov R. (Uzbekistan), Romanchuk A. (Ukraine), Shamshiev B. (Kyrgyzstan), Usheva M. (Bulgaria), Vasileva M. (Bulgar).

Engineering

Materials of conferences (Italy (Rome), 08-15 April 2018)

Priority areas of science, technology and engineering

During the drilling and operation of oil and gas wells, toxic wastes that contain a large number of chemical elements and compounds are included in the closest geographical areas of the hydrosphere and the lithosphere, where the environment is isolated. Industrial oil wastes will be after oil production and processing technology, transportation, repairs and emergencies. The most affordable way to isolate these wastes is to store them directly in the oil storages outside the drilling site or outside.

As a result of tests at the Akshabulak field, pollution of the atmosphere was caused by the evaporation of hydrocarbon gases. Their size was 3 mg / m3 from the opposite side to wind direction, 27 mg / m3 from the wind direction.

The research methodologies have been tested for aggressive components for a certain period of time in laboratory installations for strength and water impermeability. As a result of the test it is investigated the water impermeability and pressure of the polymerorganic material.

Advantages of the polymerorganic material are: the use of oil waste sludge pit, ease of production, unlimited working time, high water resistance and compression strength, resistance to aggressive components of oil wastes (corrosion resistance), low cost of work and environmental safety of this material. Increase of prospecting-exploration wells, as well as open pit mining operations are closely related to environmental degradation, environmental protection and subsoil protection have national economic importance. High toxicity of drilling waste has been proven by leading research institutes and scientists of the Republic of Kazakhstan.

During the operation of the wells, oil and condensate emissions occur. The entry of these substances into water bodies, soil, and groundwater is environmentally hazardous [1, 3; 2, 4].

During the construction and operation of wells, sludge pits barns are filled with drilling wastewater, drilling mud, formation water, well testing products, materials for preparation and chemical treatment of drilling and oil wells, fuel and lubricants, and the like. But pollutants contained in waste, due to their mobility and high penetrating ability, migrate to groundwater and pollute the environment [3, 2; 4, 3].

In publications [7, 40; 8, 15] drilling fluids, their types, purpose and chemical composition were investigated. Accordingly, these studies have identified the most common chemical components in the formulation of various drilling fluids, and their maximum possible concentration. These are chemicals with a high concentration in the formulations of drilling fluids: caustic soda (NaOH) - 2.8%, soda ash (Na2CO3) -4%, potassium chloride (KCl) - 15%. These chemicals are toxic and belong to the III-IV classes of environmental hazards. The samples were divided into four groups of 30 samples and placed in containers with the most aggressive components of drill cuttings and, for comparison, in a container with water:

- I group - water (H2O);

- II Group - 2.8% caustic soda solution (NaOH);

- III Group - 4% solution of soda ash (Na2CO3);

- IV group - 15% potassium chloride solution (KCl).

Tests of oily ground cement samples for water permeability were carried out in the process of aging in aggressive media and water after 30, 90, 180, 270, 360 days by the wet spot method on the UVF-61 unit. Before the test, the samples were kept in the laboratory room for 24 hours. Samples in the cage were installed in the sockets of the installation and reliably fixed. The water pressure was increased in steps of 0.2 MPa for 1 to 5 minutes and held at each stage for 16 hours. The tests were carried out until signs of water filtration in the form of drops or a wet spot appeared on the upper end surface of the sample. The water permeability of each sample is estimated by the maximum water pressure at which it does not yet leak through the sample.

The results of laboratory tests of oily ground cement samples for water permeability are given in Table 1, where the brand values for the waterproofness of soil cement samples are summarized, depending on the time and holding medium.

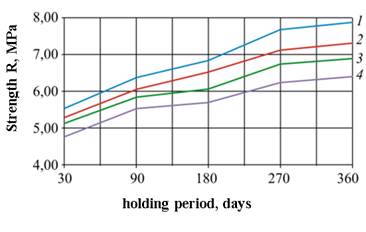

From the graph (see Fig.1) it can be seen that as the aging time in aggressive chemical solutions increases, the compressive strength of the oily ground cement has increased irrespective of the environment in which hardening of the oily ground cement took place.

This proves the possibility of its use for the construction of an anti-filtration screen of sludge pit. The oily ground-cement anti-filtration screen of the sludge pit provides effective protection of the environment and groundwater from toxic drilling waste and exploitation of oil and gas wells [5,4; 6,10].

Table 1 - Distribution according to groups of samples of soil cement, respectively, the soaking medium and the aging time for the determination of the brand by water permeability

|

sample retention medium |

Specimen holding time, the aging period of sample groups, the number of samples for testing, the brand of a group of oily ground cement samples for water resistance W |

|||||||||

|

30 days |

90 days |

180 days |

270 days

|

360 days |

||||||

|

№ |

W |

№ |

W |

№ |

W |

№ |

W |

№ |

W |

|

|

Н2О |

1-6 |

4 |

7-12 |

6 |

13-18 |

6 |

19-24 |

6 |

25-30 |

6 |

|

NaOH |

31-36 |

4 |

37-42 |

6 |

43-48 |

6 |

49-54 |

6 |

55-60 |

6 |

|

Nа2CO3 |

61-66 |

4 |

67-72 |

6 |

73-78 |

6 |

79-84 |

6 |

85-90 |

6 |

|

KC1 |

91-96 |

4 |

97-102 |

6 |

103-108 |

6 |

109-114 |

6 |

115-120 |

6 |

A new design of a sludge pit with an anti-filtration screen made of oily ground cement, where the walls of the trench of the sludge pit are insulated with a vertical anti-filtration screen from oily ground cement, using the technology of making oil and ground-cement elements in drilling-boring technology without excavation, and the bottom of the excavation is isolated by horizontal anti-filtration screen by applying a uniform layer of soil cement on the bottom of the foundation pit is mortar-pumped, which simplifies and reduces the cost of building a sludge pit.

Fig. 1- Graphs of the dependence of the strength of the oily ground cement on the period and the holding medium: 1 - water (Н20); 2 - 2,8% solution of caustic soda NaOH); 3 - 4% solution of soda ash (Na2С03); 4 - 15% solution of potassium chloride (KCl)

Conducted laboratory studies of the impact of aggressive components of drill cuttings on oily ground cement showed that over time the strength of oily ground cement has increased and, accordingly, its water permeability has increased (from W4 to W6), which indicates the stability of the oily ground cement to the drill cuttings.

Results of laboratory studies of physical characteristics of soil: density r = 1,64g / cm3; the humidity is natural: H = 0, 20; the density of the skeleton of the soil is rs= 1.37 g / cm3; humidity at the yield point Hy.p. = 0.3; the humidity at the rolling edge is Hr.e. = 0.17; the plasticity number is Np = 0.13.

2. Bisenov Kylyshbay, Abilbek Zhangyl, Tanzharikov Panabek,2016 . Research of the properties of materials based on the oil wastes.Journal of Scientific Research and Development, 3 (7), pp. 20-27.

3. Uliya Abdikerova, ZhangylAbilbek, AsylkhanShomantayev, KamalbekBaitasov, PanabekTanzharikov and NauryzbayAlibekov, 2016. Hydrotechnical Properties of Mastics on the Basis of Petroleum Bitumen Rocks (PBR). Research Journal of Applied Sciences, 11: 1623-1631

4. Shomantayev, A., Tanzharikov, P., Abdikerova, U., Abilbek, Z., Baitasov, K. Study on hydrotechnical properties of mastics on the basis of petroleum bitumen rocks(PBR)(2016) ARPN Journal of Engineering and Applied Sciences, 11 (21), pp. 12700-12704.

5. Bartolomey A.A., Brandl H., Ponomarev A.B. Fundamentals of designing the construction of waste storage facilities. - Moscow, ASV Publishing House, 2004.-144p.

6. Abilbek, Z., Tanzharikov, P., Yerimbetov, K., Abdikerova, U., Sarabekova, U.

Technology of preparation of the waterproofing material on the basis of asphalt-resin-paraffin deposits and polymer (2017) ARPN Journal of Engineering and Applied Sciences,12 (22) pp.6542-6548.

7. Testeshev A.A., Utilization of products of oil pipeline accidents for the construction of site facilities in Western Siberia, doctoral thesis, Tumen, 2001, pp.40-44.

8. Tanzharikov P. A., Abilbek Zh., A., Sarabekova U.Zh. Technology of preparation of waterproofing material based on asphalt-resin paraffin deposits and polymer // Bulletin of KazATK.-2017.- №2 (101) .- pp.18-26.

Tanzharikov P., Erken A., Abilbek Z. RESEARCH OF THE PROPERTIES OF OIL WASTE RESERVIOR WITH POLYMERORGANIC SCREEN. International Journal Of Applied And Fundamental Research. – 2018. – № 2 –

URL: www.science-sd.com/474-25386 (15.02.2026).

PDF

PDF